Heat preservation type inner wall plastering anhydrite and method

A technology for plastering plaster and interior walls, applied in the field of plaster plastering, which can solve the problems of not being too thick, poor water resistance, easy cracking, etc., and achieve the effects of less overcooling or overheating, good reversibility, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

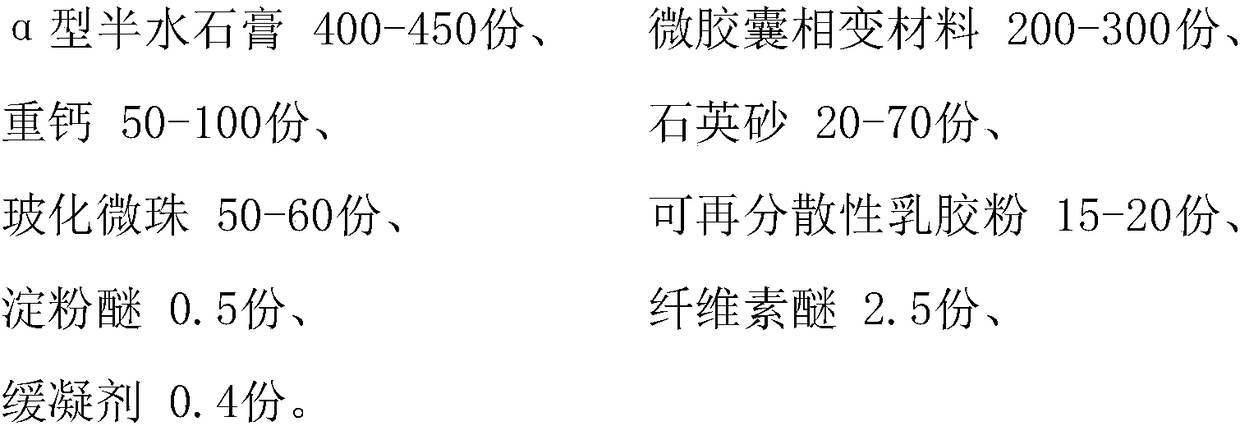

[0036] A heat-preserving plaster for interior walls, which consists of the following substances in parts by weight:

[0037]

[0038] The preparation method of above-mentioned stucco plaster is:

[0039] 1. Prepare raw materials:

[0040] Weigh the following materials in order according to parts by mass: 400 parts of α-type hemihydrate gypsum, 300 parts of microcapsule phase change material, 50 parts of 325 mesh heavy calcium, 70 parts of 70-140 mesh quartz sand, vitrified microparticles with a particle size of less than 1.5mm. 50 parts of beads, 20 parts of redispersible latex powder, 0.5 parts of starch ether, 2.5 parts of cellulose ether, and 0.4 part of retarder; among them, the whiteness of 325 mesh heavy calcium is 95%, and the content of calcium carbonate is 98%.

[0041] 2. Mixed production:

[0042] After the raw materials are ready, add the above-mentioned α-type hemihydrate gypsum, microcapsule phase change material, heavy calcium, quartz sand, and vitrified mi...

Embodiment 2

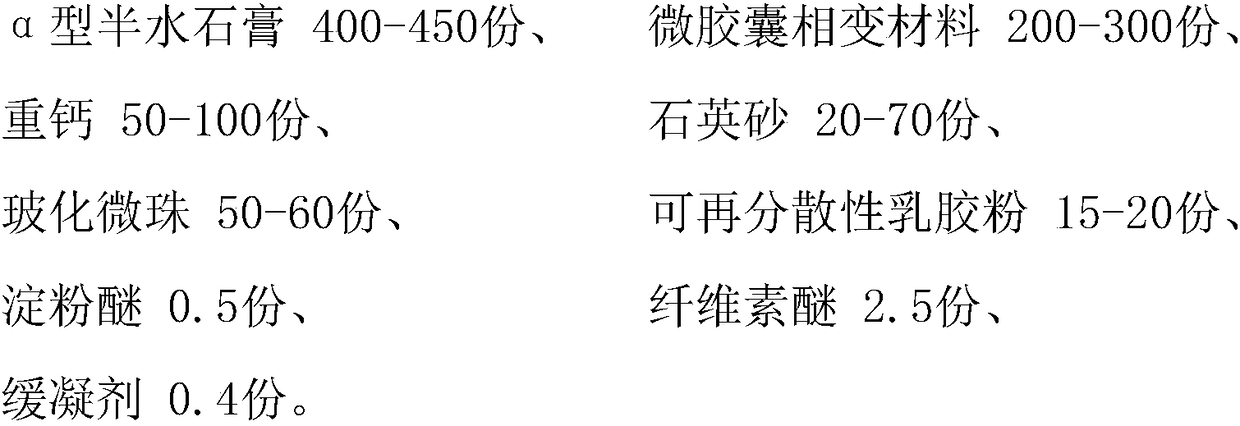

[0052] A thermal insulation type interior wall plastering plaster, which is composed of the following parts by weight:

[0053]

[0054] Except for the different parts of raw materials, the manufacturing method and using method of plastering gypsum in this embodiment are the same as those in the first embodiment.

[0055] It has been verified that the product performance of this product meets the technical indicators of GB / T28627-2012, and the main technical parameters are shown in Table 2.

[0056] Table 2

[0057] parameter

Embodiment 3

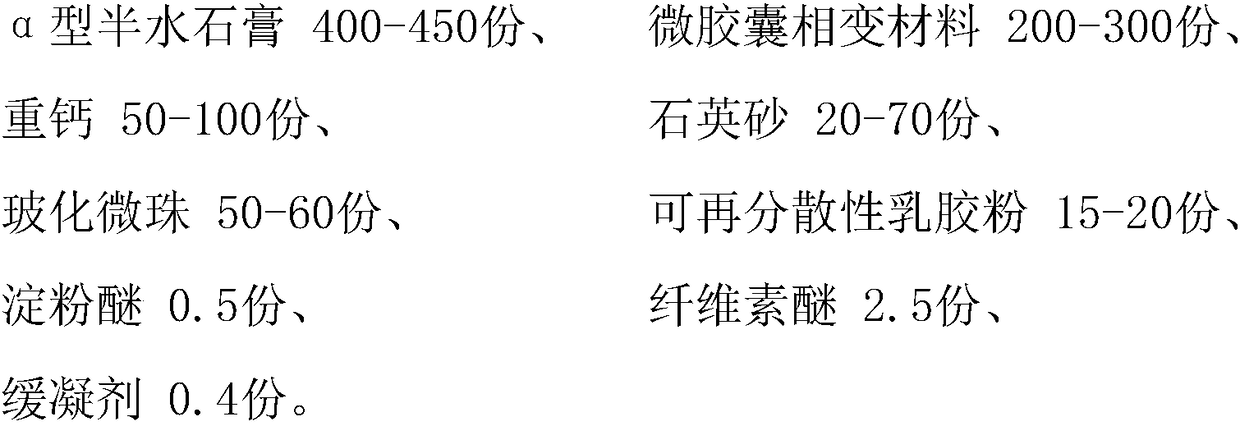

[0059] A thermal insulation type interior wall plastering plaster, which is composed of the following parts by weight:

[0060]

[0061] Except for the different parts of raw materials, the manufacturing method and using method of plastering gypsum in this embodiment are the same as those in the first embodiment.

[0062] It has been verified that the product performance of this product meets the technical indicators of GB / T28627-2012, and the main technical parameters are shown in Table 3.

[0063] table 3

[0064] parameter

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com