Equipment and production process for producing camphor by continuous gas phase dehydrogenation of isoborneol

A gas-phase dehydrogenation and isoborneol technology, which is applied in the direction of dehydrogenation preparation, carbon-based compound preparation, organic compound preparation, etc., can solve the problems of catalyst erosion and affecting the service life of catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

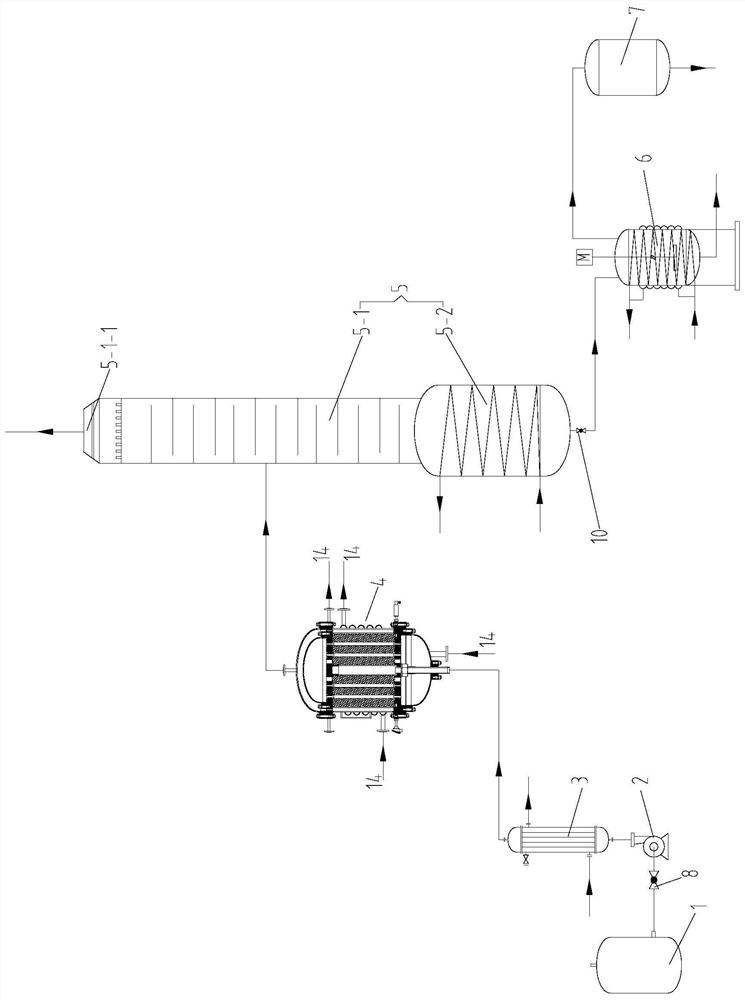

[0056] Such as figure 1 , 3 As shown, a kind of camphor equipment of continuous gas-phase dehydrogenation of isoborneol according to the present invention comprises feeding pump 2, vaporizer 3, heat exchange type radial flow dehydrogenation reactor 4, continuous rectification tower 5, sublimation Kettle 6 and desublimation chamber 7; the feeding pump 2 is connected with the liquid storage tank 1 containing the isoborneol organic solvent solution after the hydrolysis reaction, and between the feeding pump 2 and the liquid storage tank 1 The connecting pipeline is provided with a first control valve 8; the feed port of the vaporizer 3 is connected with the feeding pump 2 for inputting the isoborneol organic solvent solution after the hydrolysis reaction pumped through the feeding pump 2 into the vaporizer 3 for vaporization;

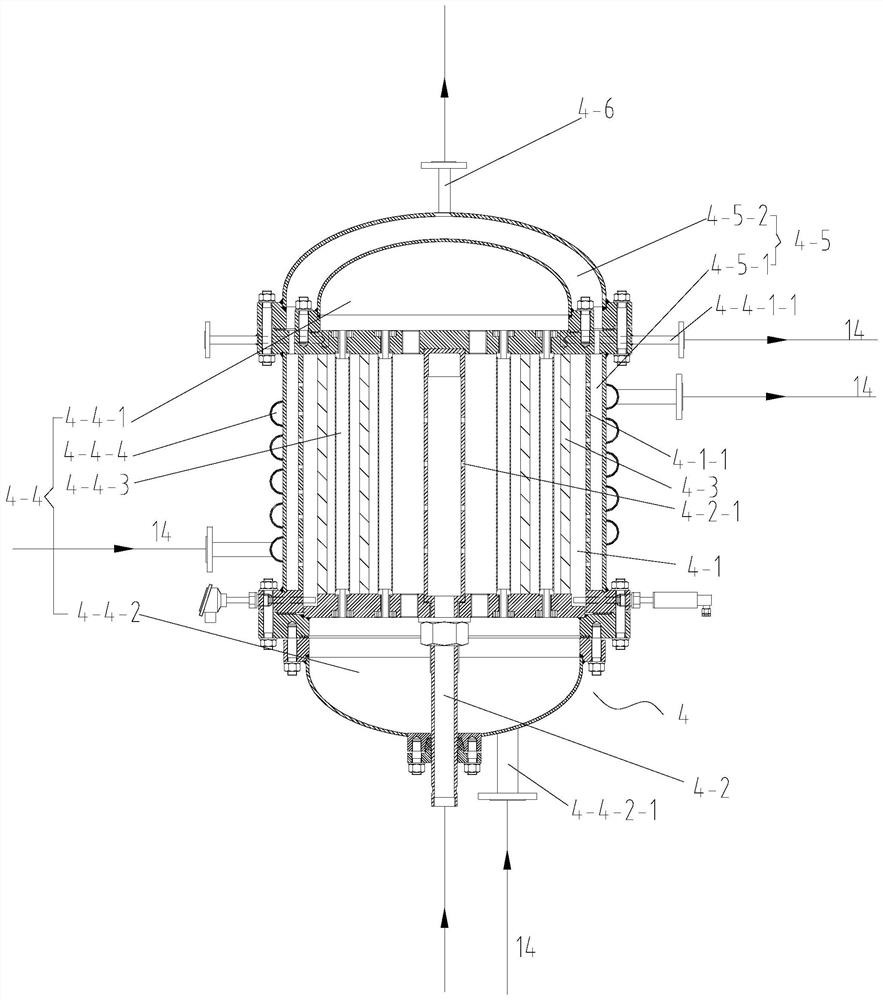

[0057] The heat exchange type radial flow dehydrogenation reactor 4 includes a dehydrogenation reaction chamber 4-1 for carrying out a dehydrogenation r...

Embodiment 2

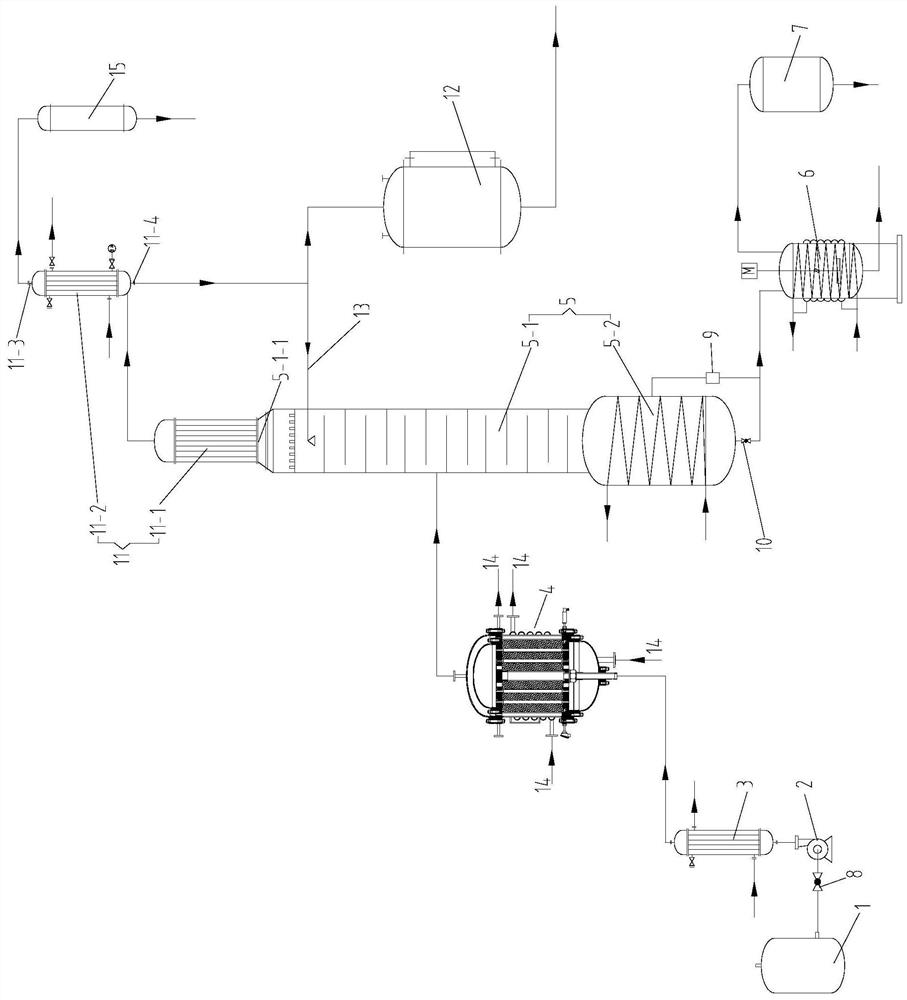

[0073] Such as Figure 2-3 As shown, a kind of camphor equipment of continuous gas-phase dehydrogenation of isoborneol according to the present invention comprises feeding pump 2, vaporizer 3, heat exchange type radial flow dehydrogenation reactor 4, continuous rectification tower 5, sublimation Kettle 6 and desublimation chamber 7; the feeding pump 2 is connected with the liquid storage tank 1 containing the isoborneol organic solvent solution after the hydrolysis reaction, and between the feeding pump 2 and the liquid storage tank 1 The connecting pipeline is provided with a first control valve 8; the feed port of the vaporizer 3 is connected with the feeding pump 2 for inputting the isoborneol organic solvent solution after the hydrolysis reaction pumped through the feeding pump 2 into the vaporizer 3 for vaporization;

[0074] The heat exchange type radial flow dehydrogenation reactor 4 includes a dehydrogenation reaction chamber 4-1 for carrying out a dehydrogenation rea...

Embodiment 3

[0096] Such as Figure 2-3 As shown, a kind of camphor equipment of continuous gas-phase dehydrogenation of isoborneol according to the present invention comprises feeding pump 2, vaporizer 3, heat exchange type radial flow dehydrogenation reactor 4, continuous rectification tower 5, sublimation Kettle 6 and desublimation chamber 7; the feeding pump 2 is connected with the liquid storage tank 1 containing the isoborneol organic solvent solution after the hydrolysis reaction, and between the feeding pump 2 and the liquid storage tank 1 The connecting pipeline is provided with a first control valve 8; the feed port of the vaporizer 3 is connected with the feeding pump 2 for inputting the isoborneol organic solvent solution after the hydrolysis reaction pumped through the feeding pump 2 into the vaporizer 3 for vaporization;

[0097] The heat exchange type radial flow dehydrogenation reactor 4 includes a dehydrogenation reaction chamber 4-1 for carrying out a dehydrogenation rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com