Color bleaching agent and preparation method thereof

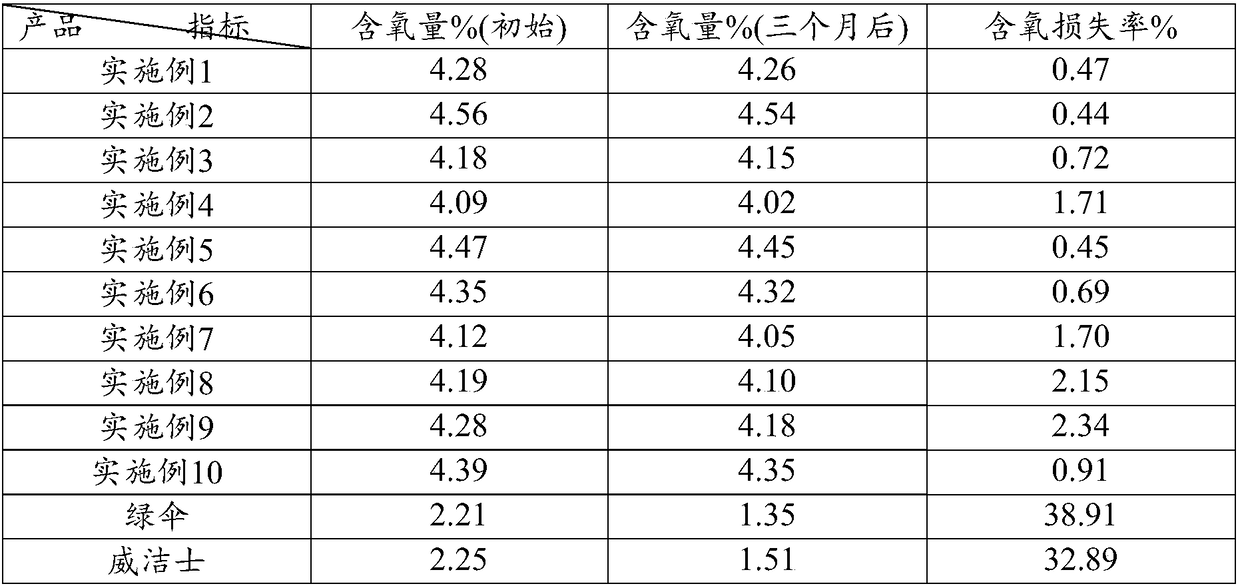

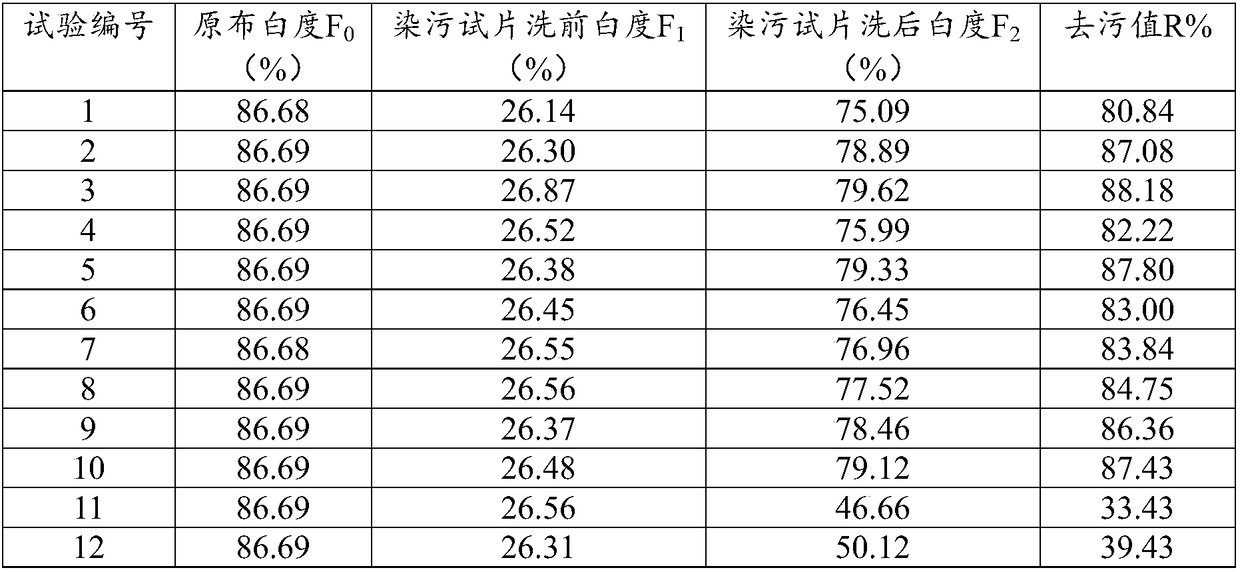

A color bleaching and active agent technology, applied in chemical instruments and methods, detergent compositions, detergent compounding agents, etc., can solve the problems of poor oxygen-containing stability, poor rinsing effect, and low oxygen content, etc. Good stability, good color protection, high oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The formula of a kind of color bleaching agent is as follows: by weight, comprises following component: nonionic surfactant (fatty alcohol polyoxyethylene ether 2%); Hydrogen peroxide 28%; Hydrogen peroxide stabilizer (tetrasodium iminodisuccinate 3% ); enzyme preparation (protease 0.3%, amylase 0.1%, cellulase 0.6%), a total of 1%; chelating agent (disodium edetate 0.3%); pH regulator (citric acid 0.2%); Alcohol ether surfactants (alkanol ether surfactants 609 2%); the balance is deionized water.

[0058] In an embodiment of the present invention, the preparation method of the above-mentioned color bleaching agent comprises the following steps:

[0059] Step 1: Weigh each component according to the above-mentioned color bleaching agent formula, and set aside.

[0060] Step 2: Add part of the deionized water into the batching pot; preferably, add 50%-60% (by weight) deionized water into the batching pot.

[0061] Step 3: Add the nonionic surfactant and the alkyl alc...

Embodiment 2

[0066] The formula of a kind of color bleaching agent is as follows: by weight, comprises following component: nonionic surfactant (fatty alcohol polyoxyethylene ether 5%); Hydrogen peroxide 30%; Hydrogen peroxide stabilizer (tetrasodium iminodisuccinate 4% ); enzyme preparation (protease 0.3%, amylase 0.2%, cellulase 1%), a total of 1.5%; chelating agent (disodium edetate 0.5%); pH regulator (citric acid 0.3%); Alcohol ether surfactants (alkanol ether surfactants 609 3%); the balance is deionized water.

[0067] In the embodiments of the present invention, the preparation method of the color bleaching agent is the same as in Example 1.

Embodiment 3

[0069] The formula of a kind of color bleaching agent is as follows: by weight, comprises following component: nonionic surfactant (fatty alcohol polyoxyethylene ether 3%); Hydrogen peroxide 28%; Hydrogen peroxide stabilizer (tetrasodium iminodisuccinate 3% ); enzyme preparation (protease 0.5%, amylase 0.7%, cellulase 0.8%), a total of 2%; chelating agent (disodium edetate 0.5%); pH regulator (citric acid 0.2%); Alcohol ether surfactants (alkanol ether surfactants 609 3.5%); the balance is deionized water.

[0070] In the embodiments of the present invention, the preparation method of the color bleaching agent is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com