Method for quantitatively measuring organic matter content in gypsum

A technology for quantitative measurement and organic matter, which is applied in the field of quantitatively measuring the content of organic matter in gypsum, can solve the problems of measuring organic matter in natural gypsum and desulfurized gypsum, etc., and achieve the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A gypsum in Example 1 is natural gypsum clinker from Shandong, B gypsum in Example 2 is desulfurized gypsum clinker from Hebei, and C gypsum in Example 3 is desulfurized gypsum raw meal from Shandong .

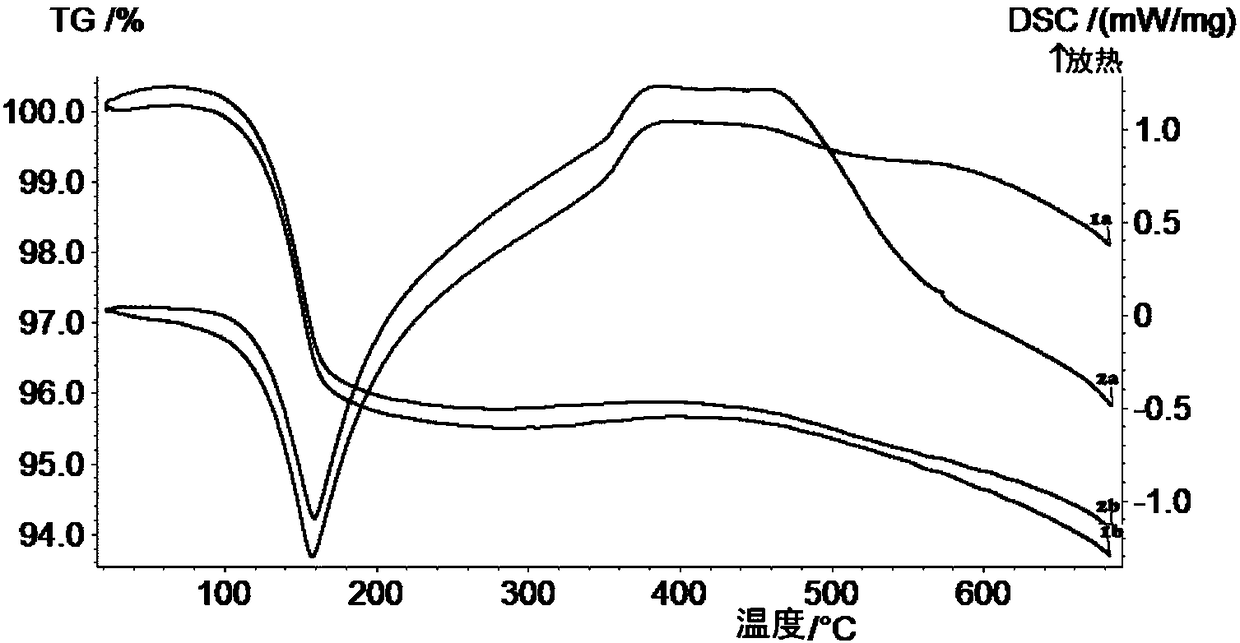

[0027] Example 1

[0028] Weigh two samples of A gypsum clinker with a mass of 21.17 mg, and use a synchronous thermal analyzer (the instrument model is NETZSCH STA 449C) to perform DSC-TG thermal analysis measurements in nitrogen and oxygen atmospheres respectively, from room temperature at a speed of 5min / °C (25°C) to 700°C. The thermal analysis curve of A gypsum clinker sample under nitrogen and oxygen atmosphere is as follows figure 1 1a and 2a represent the DSC curves under nitrogen and oxygen atmospheres, respectively, and 1b and 2b represent the TG curves under nitrogen and oxygen atmospheres, respectively.

[0029] It can be seen from the figure that the thermal analysis curves under the two atmospheres are basically the same. An endothermic peak appeared at...

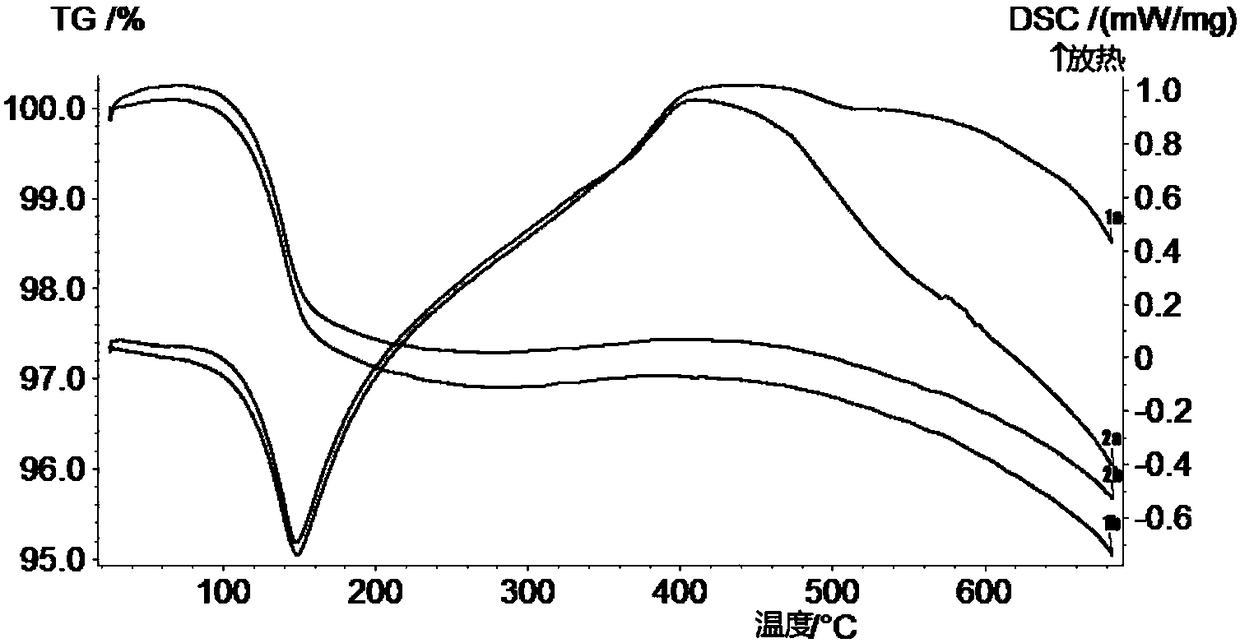

Embodiment 2

[0031] Weigh two samples of B gypsum clinker with a mass of 21.79 mg, and use a synchronous thermal analyzer (instrument model NETZSCH STA 449C) to perform DSC-TG thermal analysis and measurement in nitrogen and oxygen atmospheres respectively, from room temperature at a speed of 5min / °C (25°C) to 700°C. The thermal analysis curve of B gypsum clinker sample under nitrogen and oxygen atmosphere is as follows figure 2 1a and 2a represent the DSC curves under nitrogen and oxygen atmospheres, respectively, and 1b and 2b represent the TG curves under nitrogen and oxygen atmospheres, respectively.

[0032] It can be seen from the figure that the thermal analysis curves under the two atmospheres are basically the same. An endothermic peak appeared at 149°C, accompanied by obvious weight loss, which was caused by the dehydration of hemihydrate gypsum; an exothermic peak appeared at about 403°C, but no weight loss occurred, which is type AIII anhydrous gypsum Caused by conversion to...

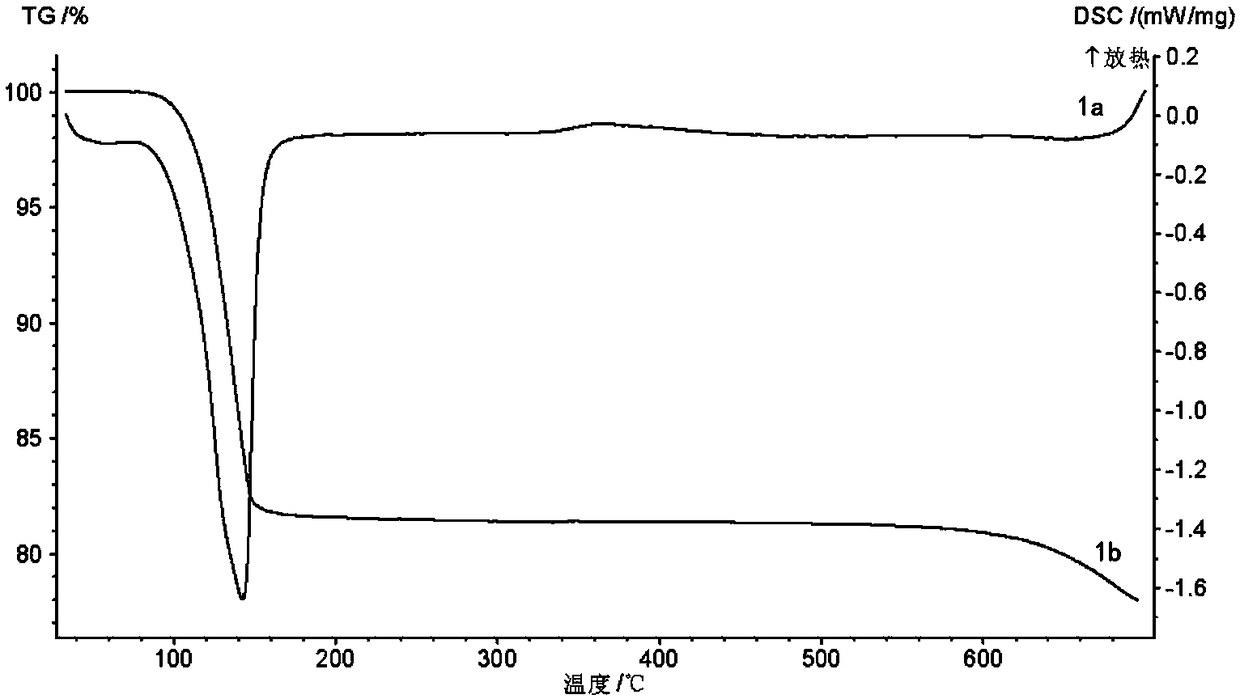

Embodiment 3

[0034] Weigh two 21.22 mg C gypsum raw material samples, and use a synchronous thermal analyzer (the instrument model is NETZSCH STA 449C) to perform DSC-TG thermal analysis measurements in a nitrogen atmosphere and DTA-TG thermal analysis measurements in an oxygen atmosphere. For analysis and measurement, the temperature was raised from room temperature (20°C) to 700°C at a rate of 5min / °C. The thermal analysis curves of C gypsum raw meal samples under nitrogen and oxygen atmospheres are as follows Figure 3(a) and 3(b) 1a and 1b represent the DSC curve and TG curve under nitrogen atmosphere, respectively, and 2a and 2b represent the DTA curve and TG curve under oxygen atmosphere, respectively.

[0035] It can be seen from Figure 3(a) that a broad endothermic peak appeared at 142°C under nitrogen conditions, accompanied by obvious weight loss, which was caused by the dehydration of dihydrate gypsum and hemihydrate gypsum; at 363 There is an exothermic peak around ℃, but no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com