Polymer-coating silicon/lithium metasilicate cathode material and preparation method thereof

A lithium metasilicate and negative electrode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of no very effective method and poor cycle stability of micron-scale silicon-based negative electrode, and achieve high specific capacity and easy operation. and industrial production, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

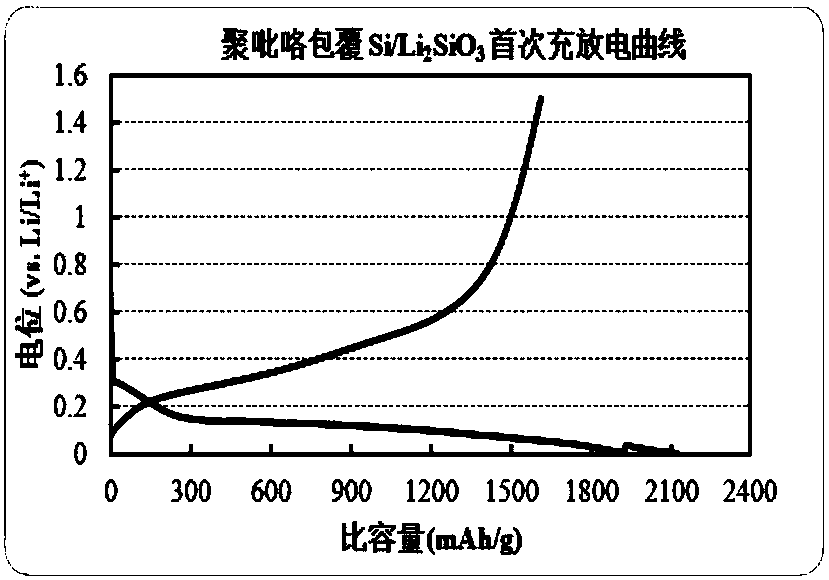

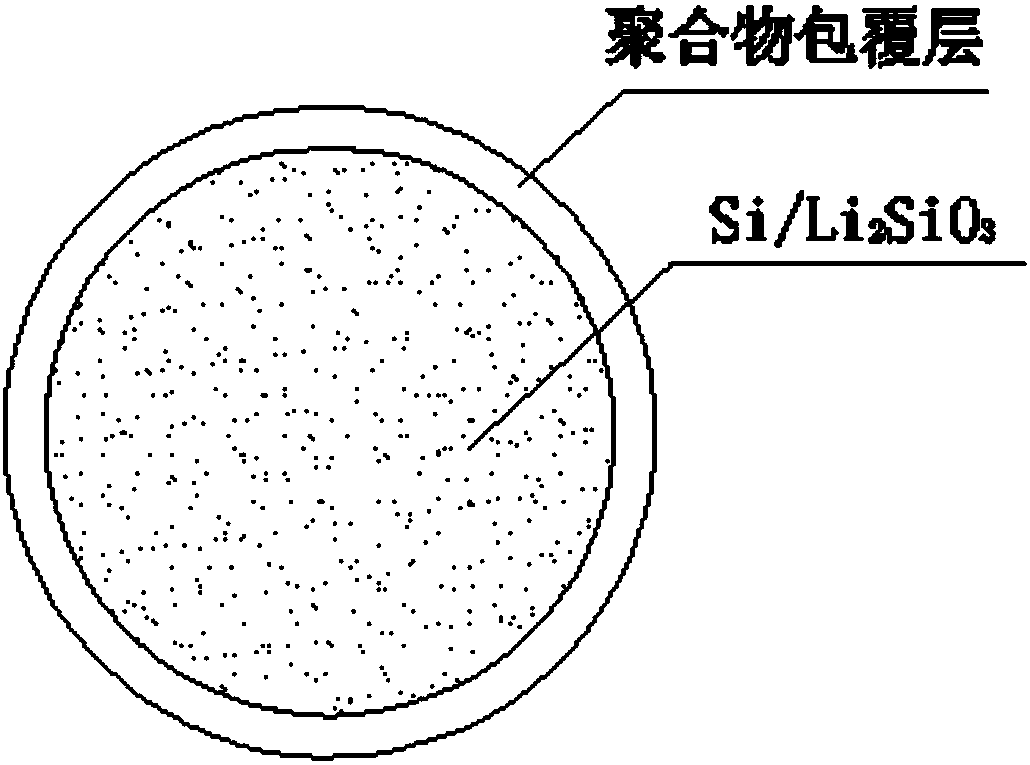

[0026] A kind of polymer coated silicon / lithium metasilicate negative electrode material that present embodiment proposes, it is made of silicon / lithium metasilicate composite material (Si / Li 2 SiO 3 ) and a polypyrrole coating layer (P) coated on the silicon / lithium metasilicate composite material, wherein the silicon / lithium metasilicate composite material accounts for 95% by weight, and the polypyrrole coating layer The percentage by weight is 5%, and its composition is [Si / Li 2 SiO 3 ] 0.95 / P 0.05 ;

[0027] A preparation method of the polymer-coated silicon / lithium metasilicate negative electrode material proposed in this embodiment comprises the following steps:

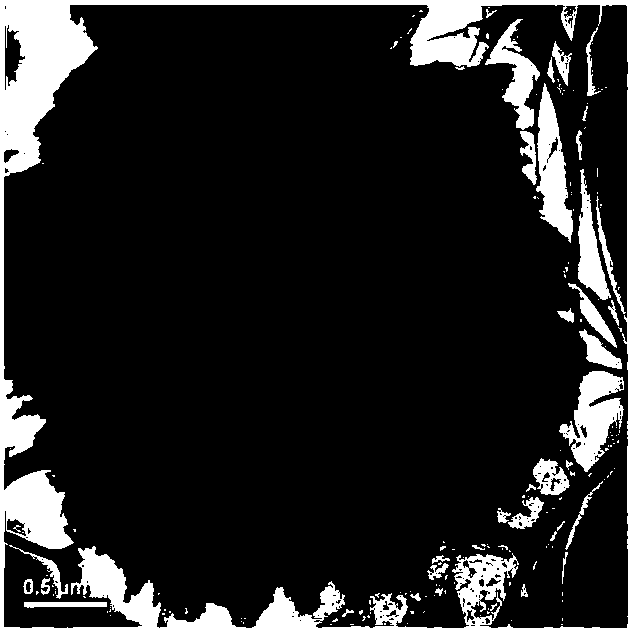

[0028] S1. Preparation of silicon / lithium metasilicate composite material Si / Li 2 SiO 3 : 5.0g of silicon oxide and 0.5g of metal lithium powder were mechanically ball milled and mixed for 1h under an argon atmosphere to obtain a silicon / lithium metasilicate composite material Si / Li 2 SiO 3 ;

[0029...

Embodiment 2

[0034] A kind of polymer coated silicon / lithium metasilicate negative electrode material that present embodiment proposes, it is made of silicon / lithium metasilicate composite material (Si / Li 2 SiO 3 ) and a polyaniline coating layer (P) coated on the silicon / lithium metasilicate composite material, wherein the silicon / lithium metasilicate composite material accounts for 95% by weight, and the polyaniline coating layer The percentage by weight is 5%, and its composition is [Si / Li 2 SiO 3 ] 0.95 / P 0.05 ;

[0035] A preparation method of the polymer-coated silicon / lithium metasilicate negative electrode material proposed in this embodiment comprises the following steps:

[0036] S1. Preparation of silicon / lithium metasilicate composite material Si / Li 2 SiO 3 : 5.0g of silicon oxide and 0.5g of metal lithium powder were mechanically ball milled and mixed for 1h under an argon atmosphere to obtain a silicon / lithium metasilicate composite material Si / Li 2 SiO 3 ;

[0037...

Embodiment 3

[0040] A kind of polymer coated silicon / lithium metasilicate negative electrode material that present embodiment proposes, it is made of silicon / lithium metasilicate composite material (Si / Li 2 SiO 3) and a polypyrrole coating layer (P) coated on the silicon / lithium metasilicate composite material, wherein the silicon / lithium metasilicate composite material accounts for 98% by weight, and the polypyrrole coating layer The percentage by weight is 2%, and its composition is [Si / Li 2 SiO 3 ] 0.98 / P 0.02 ;

[0041] A preparation method of the polymer-coated silicon / lithium metasilicate negative electrode material proposed in this embodiment comprises the following steps:

[0042] S1. Preparation of silicon / lithium metasilicate composite material Si / Li 2 SiO 3 : 5.0g of silicon oxide and 0.5g of metal lithium powder were mechanically ball milled and mixed for 0.5h under an argon atmosphere to obtain a silicon / lithium metasilicate composite material Si / Li 2 SiO 3 ;

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com