Metal air battery, battery pack and device applying the same

A metal-air battery and battery cell technology, which is applied to fuel cell-type half-cells, primary battery-type half-cells, and hybrid battery components, etc. Limitations and other problems, to achieve the effect of easy centralized management and maintenance, uniform chemical reaction of the battery, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

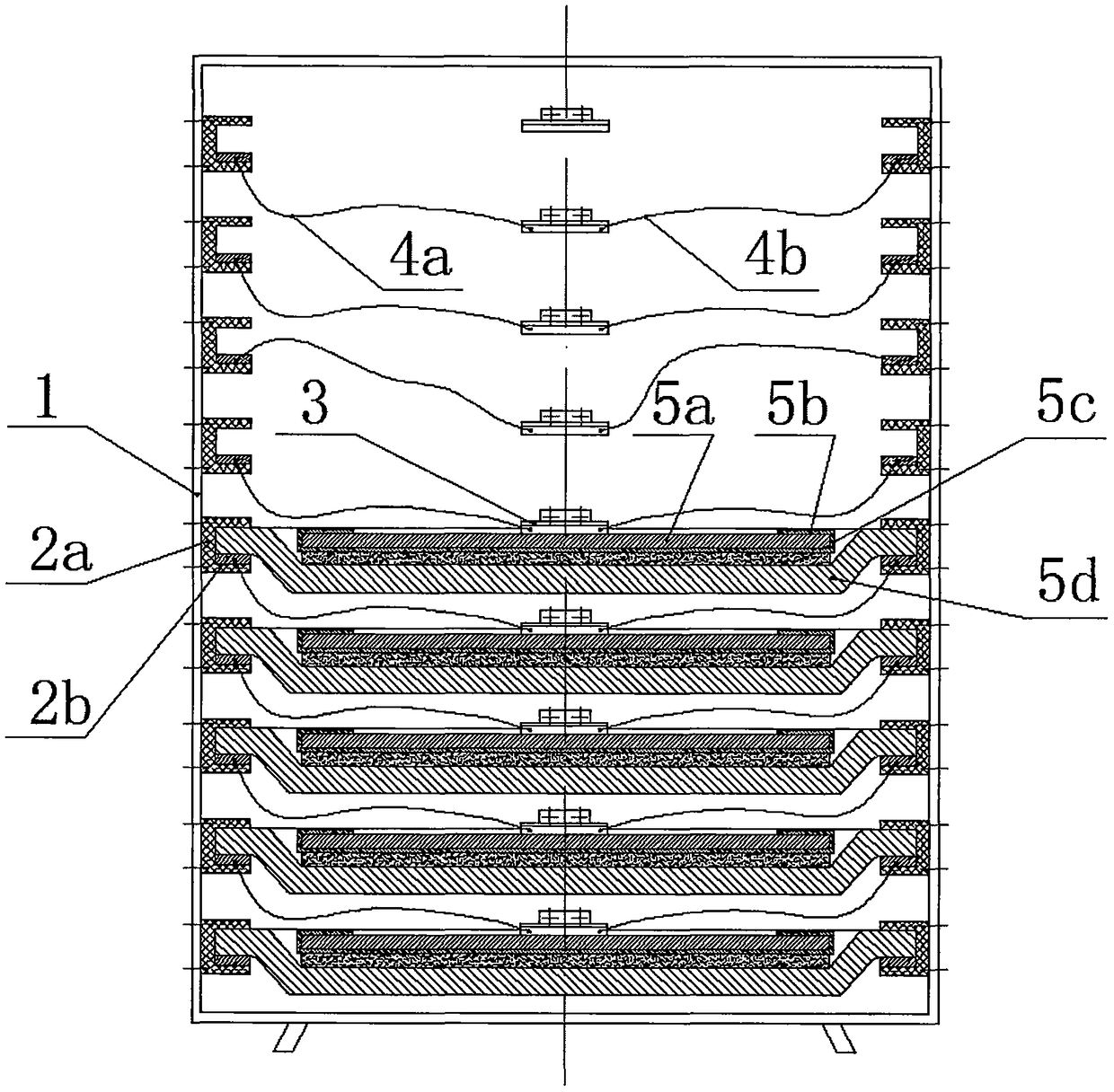

[0030] figure 1 Is a schematic cross-sectional view of the overall structure of the battery cell units connected in series according to an embodiment of the present invention, figure 1 In the instrument box (1), multiple symmetrical slots (2a) are provided on the left and right sides, and conductive elements (2b) are provided in the symmetrical slots (2a). The conductive elements (2b) also serve as the positive output. It is insulated from the meter box (1) and connected to the positive current collector layer (5d).

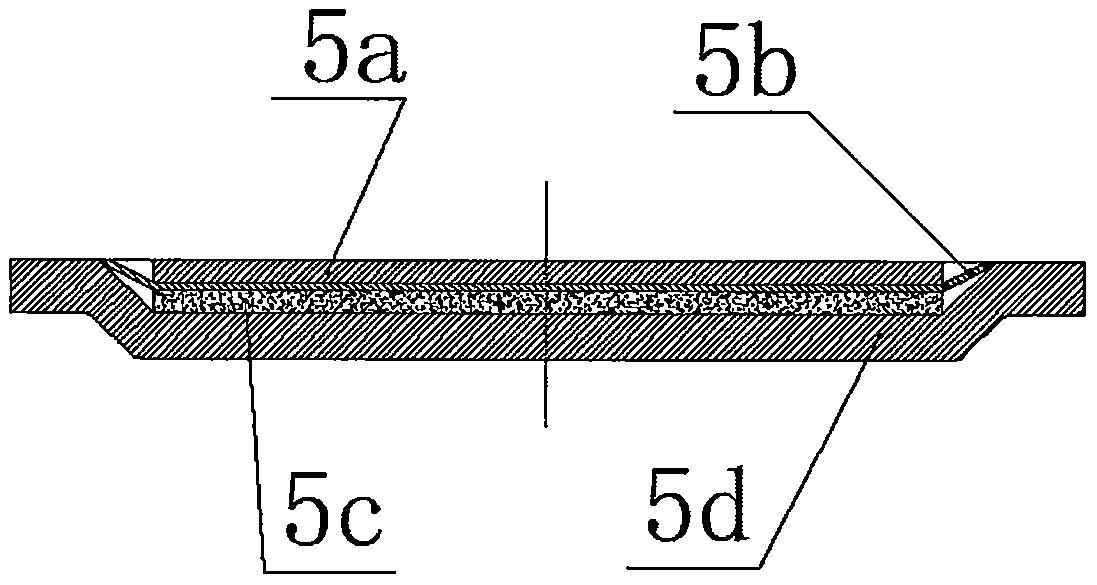

[0031] The battery core unit is composed of a metal negative electrode layer (5a), a separator layer (5b), an air positive electrode layer (5c), and a positive electrode current collector layer (5d) sequentially stacked from top to bottom.

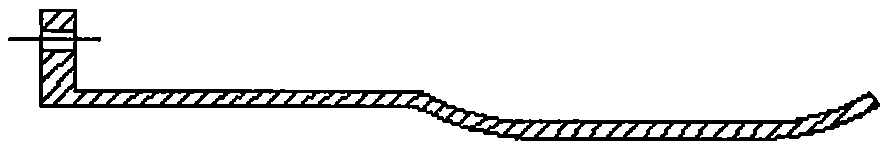

[0032] The elastic member (3) is a conductive material, which also serves as a negative output, and is fixed on the inside of the back of the meter box (1). The other end of the elastic member (3) is pressed against the metal negat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com