Preparation and application methods of Cu2O-AC (activated carbon) photocatalyst

A photocatalyst and activated carbon technology, applied in the fields of photocatalysis and comprehensive utilization of resources, can solve the problem of high production cost, and achieve the effects of short reaction time, simple operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The Cu 2 The preparation method of O-AC photocatalyst, its concrete steps are as follows:

[0025] Step 1. First put the discarded activated carbon (the activated carbon is 150 mesh, and the methylene blue value is 30 mg / g) in distilled water, wash it with a 50W ultrasonic wave at room temperature for 60 minutes, and then dry it at 105°C for 12 hours;

[0026] Step 2. Mix the waste activated carbon cleaned in step 1 with CuO powder at a mass ratio of 4:1, and roast for 20 minutes under the conditions of an inert gas (nitrogen) pressure of 3 MPa, a microwave power of 400 W, and a roasting temperature of 700 ° C to prepare Cu 2 O-AC photocatalyst.

[0027] The above Cu 2 O-AC photocatalyst application, the Cu 2 O-AC can be used to adsorb dye wastewater and photocatalyze the degradation of malachite green dye.

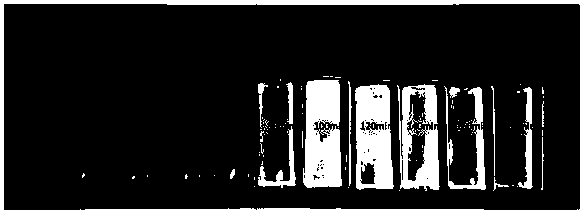

[0028] Cu prepared by the above steps 2 The methylene blue value of the O-AC photocatalyst was 150 mg / g, and the degradation rate of malachite green with an i...

Embodiment 2

[0030] The Cu 2 The preparation method of O-AC photocatalyst, its concrete steps are as follows:

[0031] Step 1. First put the discarded activated carbon (the activated carbon is 200 mesh, the methylene blue value is 45mg / g) in distilled water, wash it with ultrasonic power of 100W at room temperature for 180min, and then dry it at 105℃ for 12h;

[0032] Step 2. Mix the waste activated carbon cleaned in step 1 with CuO powder at a mass ratio of 5:2, and roast for 30 minutes under the conditions of an inert gas (nitrogen) pressure of 3 MPa, a microwave power of 400 W, and a roasting temperature of 800 ° C to prepare Cu 2 O-AC photocatalyst.

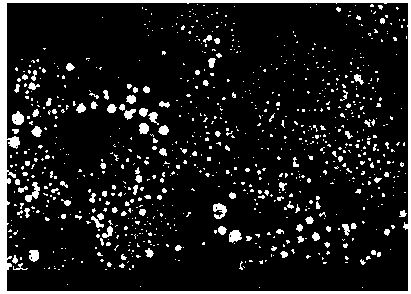

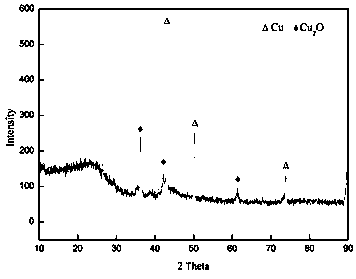

[0033] The Cu prepared in this example 2 The scanning electron microscope image of O-AC is as follows figure 1 shown, from figure 1 It can be seen that the modified activated carbon is supported by the formed metal microcrystals, the surface of activated carbon has less collapse phenomenon, and the Cu on the surface of activated carbo...

Embodiment 3

[0038] The Cu 2 The preparation method of O-AC photocatalyst, its concrete steps are as follows:

[0039] Step 1. First put the discarded activated carbon (the activated carbon is 300 mesh, the methylene blue value is 60mg / g) in distilled water, wash it with an ultrasonic wave with a power of 80W at room temperature for 120min, and then dry it at 105°C for 12h;

[0040] Step 2. Mix the waste activated carbon cleaned in step 1 with CuO powder at a mass ratio of 3:2, and roast for 30 minutes under the conditions of an inert gas (nitrogen) pressure of 2 MPa, a microwave power of 200 W, and a roasting temperature of 300 ° C to prepare Cu 2 O-AC photocatalyst.

[0041] The above Cu 2O-AC photocatalyst application, the Cu 2 O-AC can be used to adsorb dye wastewater and photocatalyze the degradation of malachite green dye.

[0042] Cu prepared by the above steps 2 The methylene blue value of the O-AC photocatalyst was 135 mg / g, and the degradation rate of malachite green with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com