Difunctional electrocatalyst

An electrochemical and catalyst technology, which is applied in the field of dual-functional electrochemical catalysts, can solve problems that do not meet the energy development strategy, low earth content, and low catalytic activity, and achieve excellent electrocatalytic oxygen reduction performance, improved electrocatalytic activity, Mo resource rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

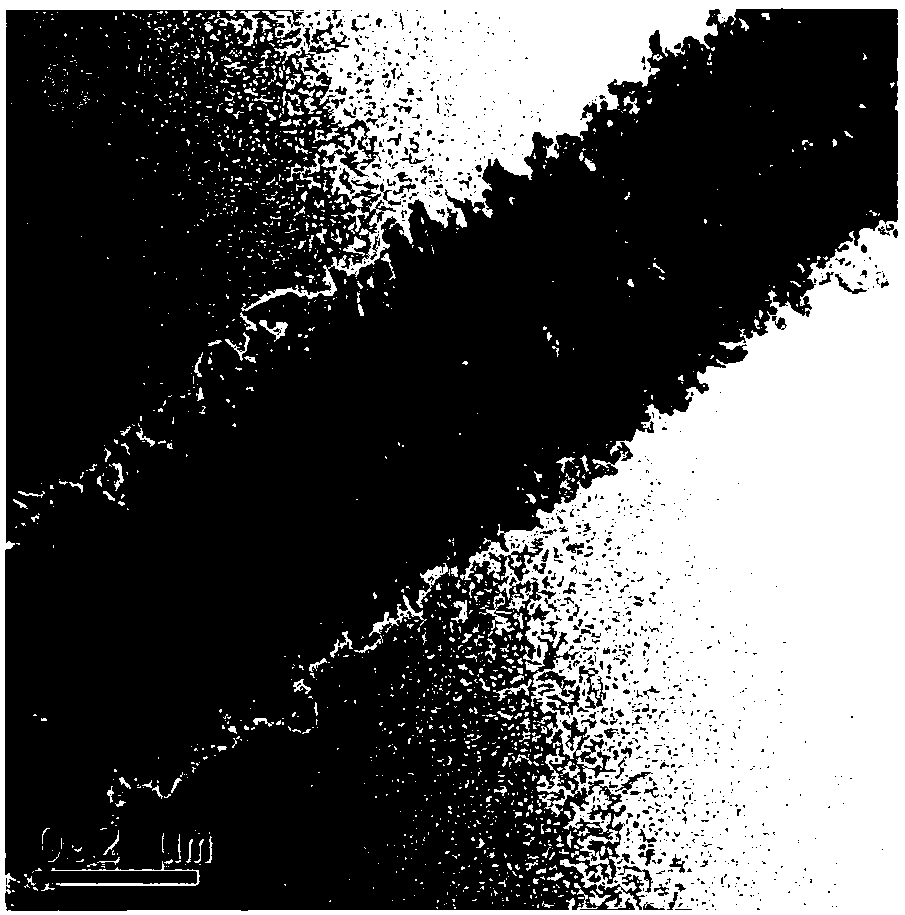

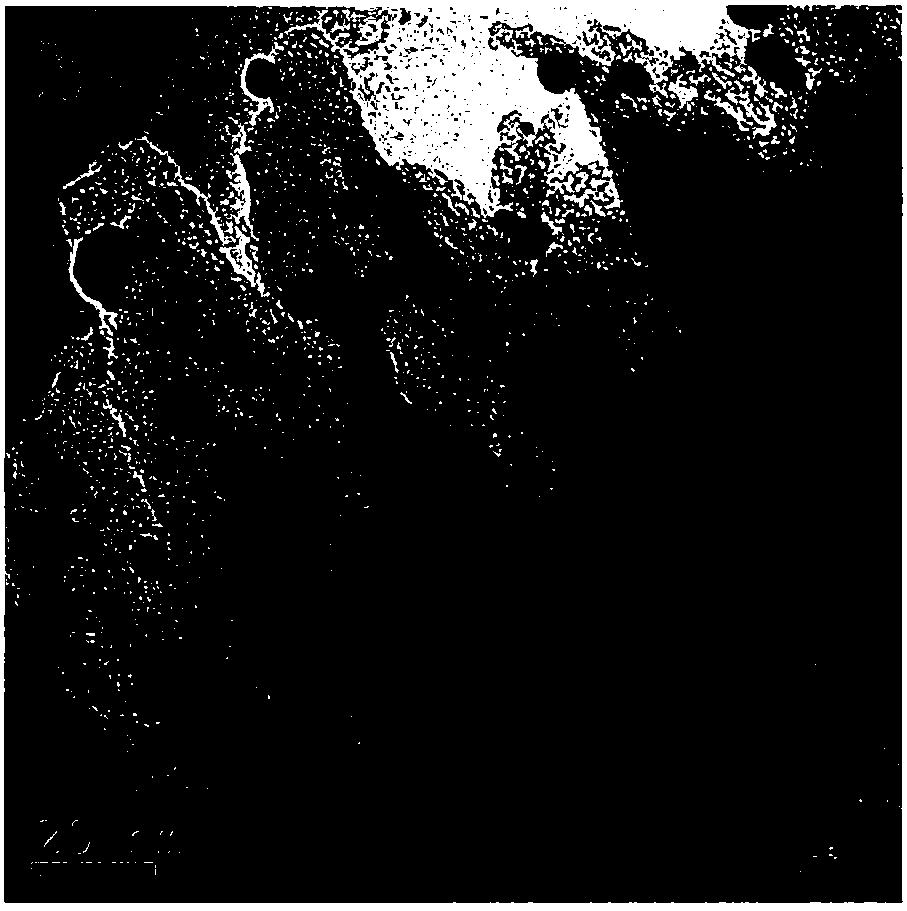

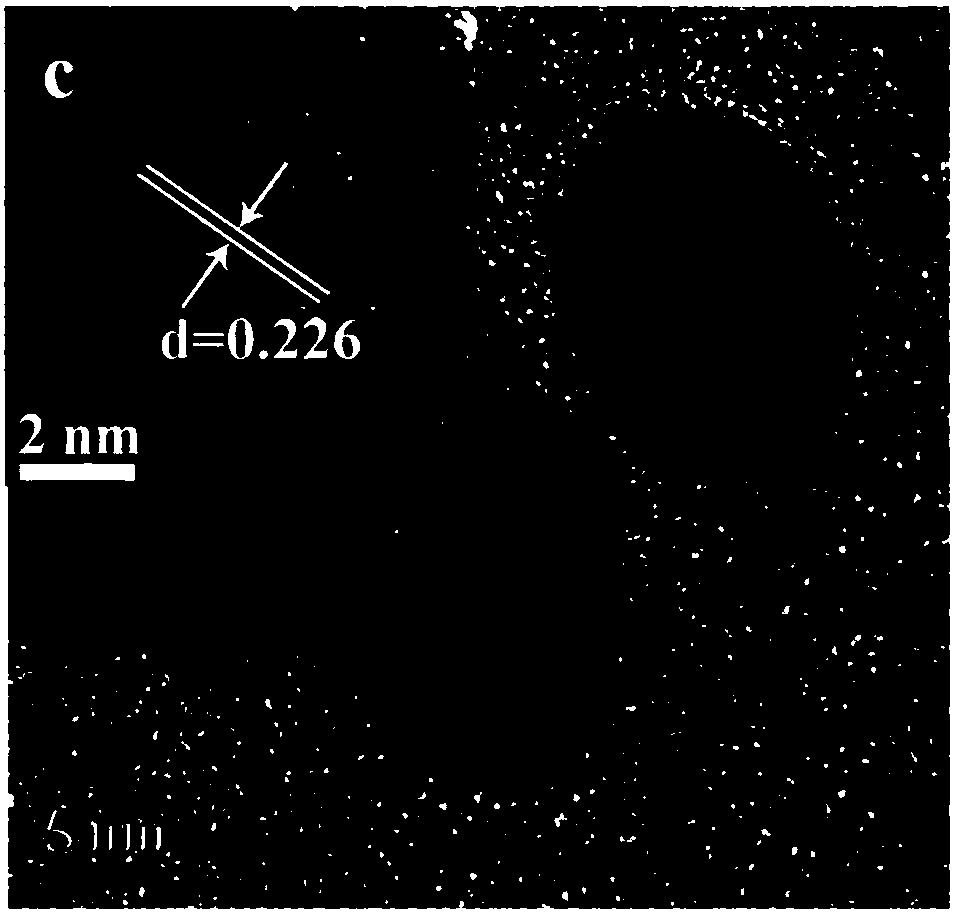

Image

Examples

Embodiment 1

[0043] Table 1

[0044]

β-Mo 2 The mass ratio of C to element Pd

β-Mo 2 C-Pd-9%

1:0.09

β-Mo 2 C-Pd-6%

1:0.06

β-Mo 2 C-Pd-3%

1:0.03

β-Mo 2 C-Pd-12%

1:0.12

[0045] 1. Preparation of β-Mo with different Pd contents as shown in Table 1 2 C-based composite catalyst with β-Mo 2 C-Pd-9% as an example, the following is its specific preparation process:

[0046] 1) Add 20mL of HNO with a volume ratio of 1:5 3 (65%) and the mixed solution of deionized water are poured in the 100mL beaker, add 700mg ammonium heptamolybdate tetrahydrate, obtain the first mixed solution after dissolving completely; The first mixed solution is transferred in the 50mL autoclave, in Perform heating reaction at 200° C. and keep for 20 hours; centrifuge, wash the filter cake with deionized water for 3 to 5 times, and dry the product in a vacuum oven at 50° C. to obtain the first precursor.

[0047] 2) Take 200mg of the first precursor and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com