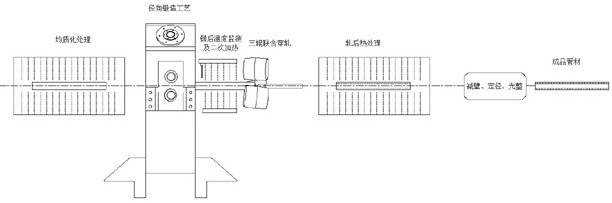

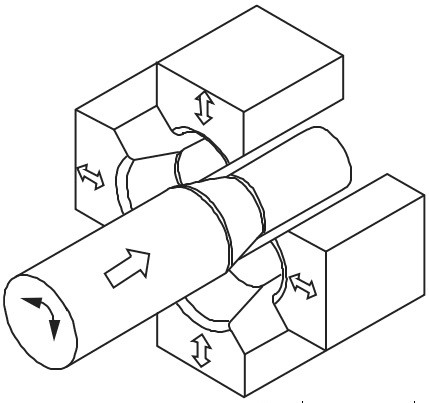

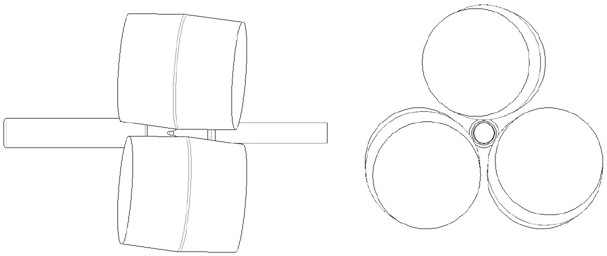

A magnesium alloy seamless pipe diameter forging piercing rolling process

A magnesium alloy and seamless pipe technology, applied in the field of magnesium alloy seamless pipe preparation, can solve the problems of difficulty in achieving three-dimensional compressive stress on the inner wall of the pipe, affecting the process performance of the pipe, and low yield of the pipe, avoiding the chilling phenomenon, The effect of improving the internal microstructure and high efficiency of pipe penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the present invention will be clearly and completely described below in conjunction with specific embodiments of the present invention. Based on the solutions in the present invention, all other solutions obtained by those of ordinary skill in the art without creative work, All belong to the protection scope of the present invention.

[0025] The magnesium alloy material used in this example is as-cast AK60, and its chemical composition is shown in Table 1 according to the inspection standard GB / T 13748.20-2009. The size specification of the magnesium alloy bar raw material is Φ142×780.

[0026] chemical composition ZN Zr Fe Cu Ni mn Al be Si Mass fraction / % 5.35 0.57 0.0026 0.0011 0.0017 0.012 0.004 0.0001 0.0025

[0027] Firstly, the surface of the bar is ground and polished on a grinding machine, and the grinding allowance on one side is 1mm. After the ground bar is cleaned by a high-speed blower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com