Closed type forging technology of light and thin type conjunction gear

A closed-type forging and closed-tooth-type technology, which is applied in the field of light and thin type combined with closed-tooth forging technology, can solve problems such as unsuitability for rolling and expansion molding, achieve good hardenability and carburizing ability, improve utilization rate, and improve quenching. The effect of permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

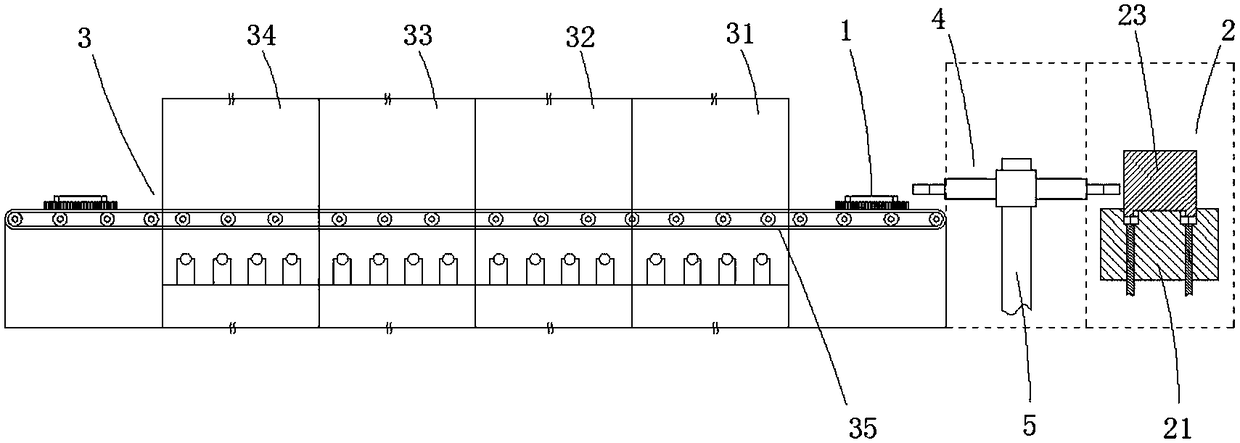

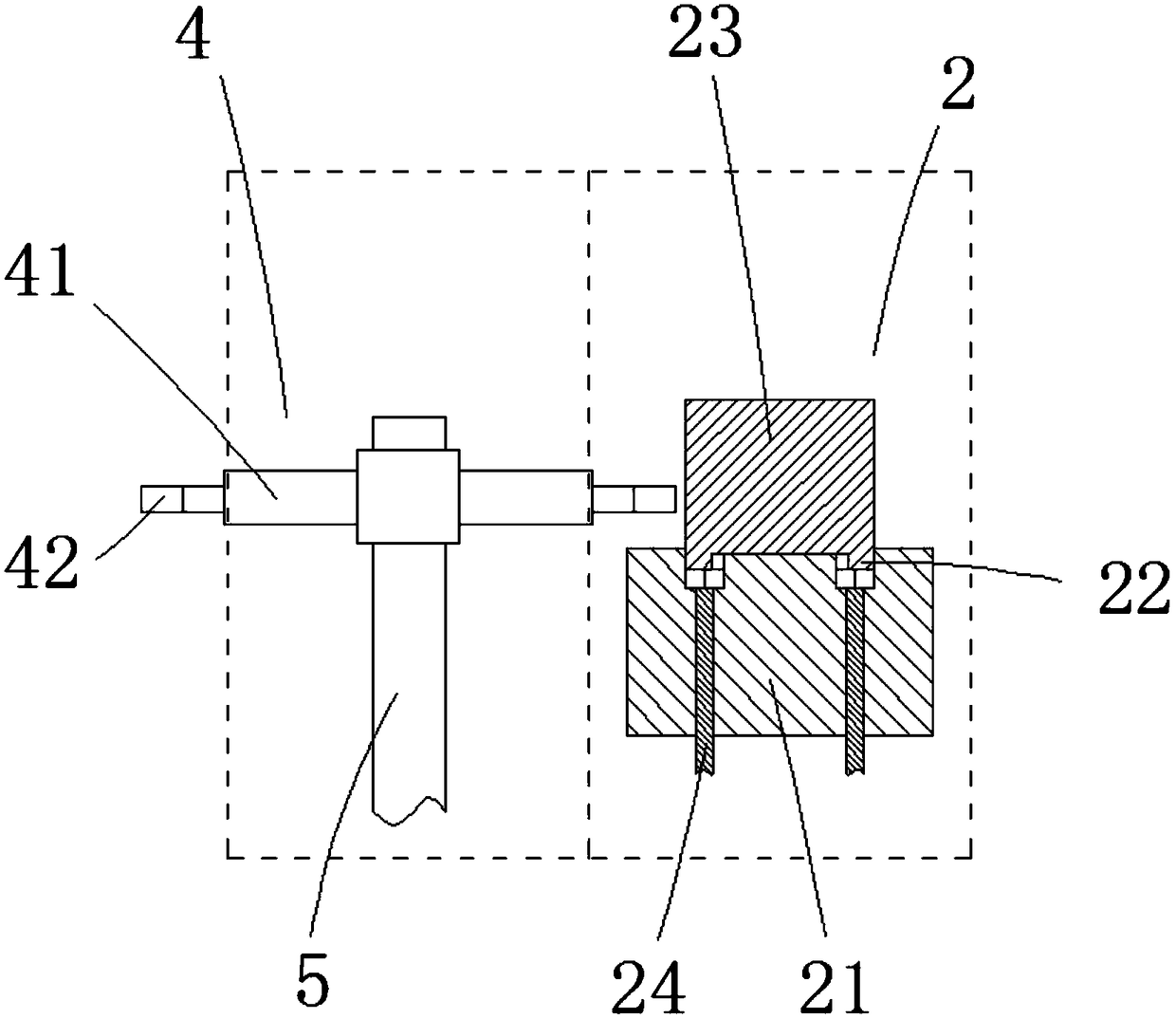

[0026] A light and thin combined tooth closed forging process of the present invention, such as Figure 1 to Figure 3 shown, including the following steps:

[0027] 1) Feeding; the raw material is carburized steel, and the mass percentage of its composition is: C: 0.25%~0.3%, Si: 0.15%~0.35%, Cr: 0.15%~0.5%, Mn: 0.3%~1.2%, Ni : 2%~3%, Mo: 0.5%~0.75%, V: 0.05%~0.15%, W: 0.8%~1.2%, Ti: 0.035%~0.05%, B: 0.001%~0.005%, Rem: 0.01 %~0.015%, S≤0.02%, P≤0.02%, the balance is Fe;

[0028] 2) Pre-forging;

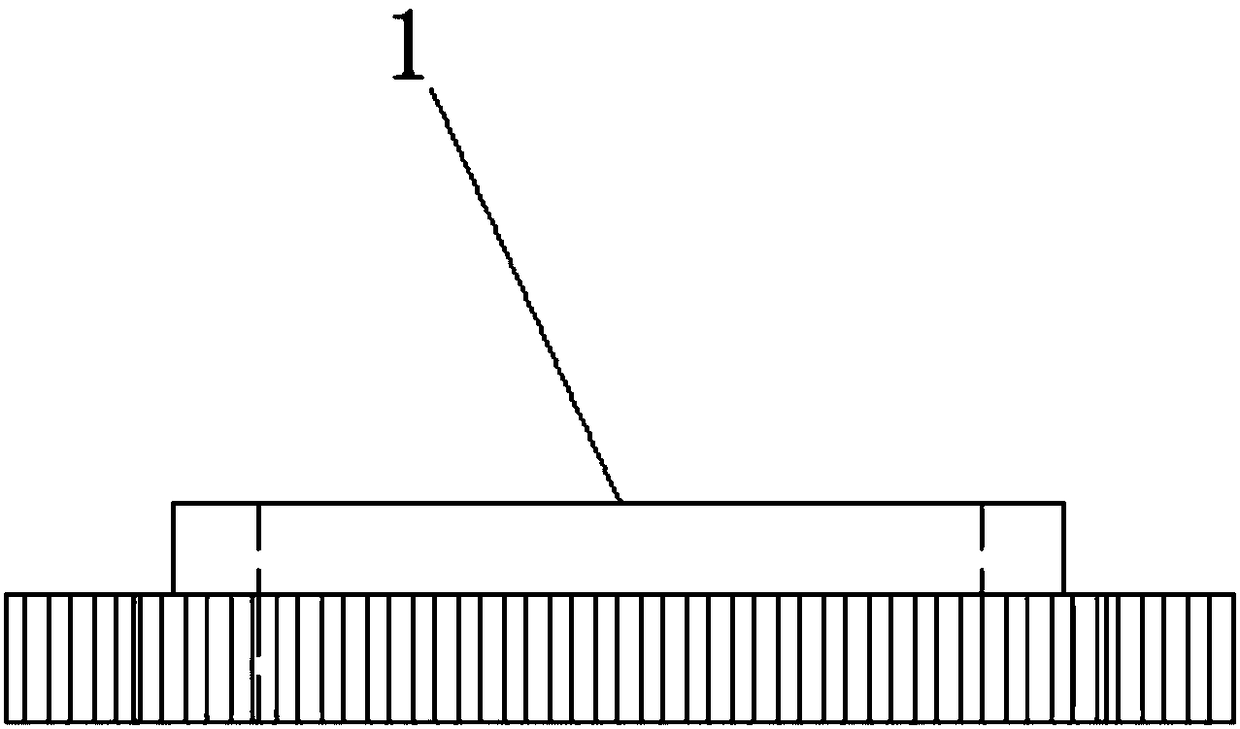

[0029] 3) Reaming, using a cold rolling ring machine to expand the inner diameter of the workpiece 1 to the target size;

[0030] 4) Heating workpiece 1;

[0031] 5) Final forging, forging the workpiece 1 through the closed forging die 2;

[0032] 6) Normalizing by using the residual heat of forging, the normalizing is isothermal normalizing;

[0033] 7) Carburizing, using carburizing technology to carry out surface hardening treatment on the whole workpiece 1;

[0034] 8) Que...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com