Mine tailing waste water cyclic utilization system

A waste water recycling and tailings technology, applied in mining waste water treatment, multi-stage water treatment, water/sewage multi-stage treatment, etc. The effect of impurity content, simple system structure and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

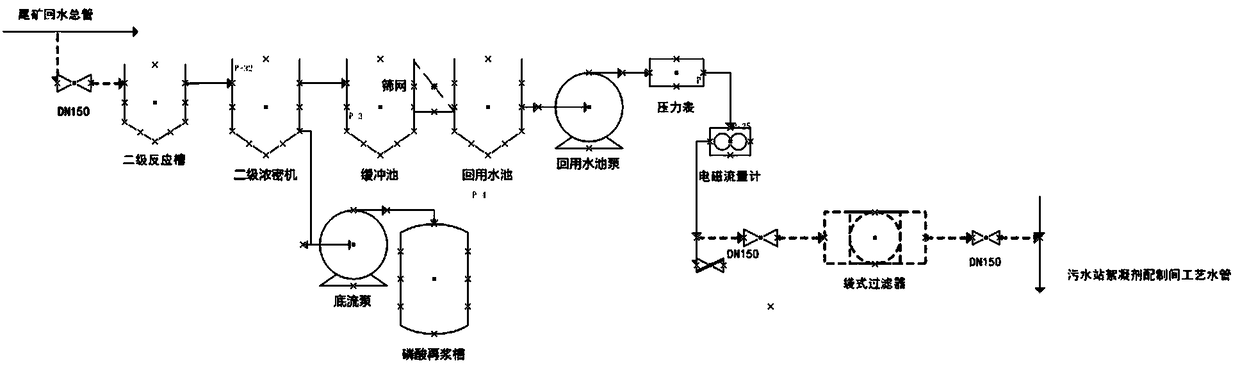

[0040] The present invention provides a tailings wastewater recycling system, comprising: a solid-liquid separation unit, a solid collection unit, a liquid collection unit, and a filter unit. The solid-liquid separation unit is connected to the solid collection unit and the liquid collection unit, respectively. The liquid collection unit is connected to the filter unit, the solid-liquid separation unit includes a reaction tank and a thickener connected in sequence, the solid collection unit includes an underflow pump and a phosphoric acid reslurry tank, and the liquid collection unit includes a sequential connection The buffer tank and the pool, the filter unit includes a bag filter and a flocculant configuration tank connected in sequence, the thickener has two upper and lower outlets, and the upper outlet of the thickener is connected to the inlet of the buffer tank, so The lower outlet of the thickener is connected with the inlet of the underflow pump, the middle of the buffe...

Embodiment 2

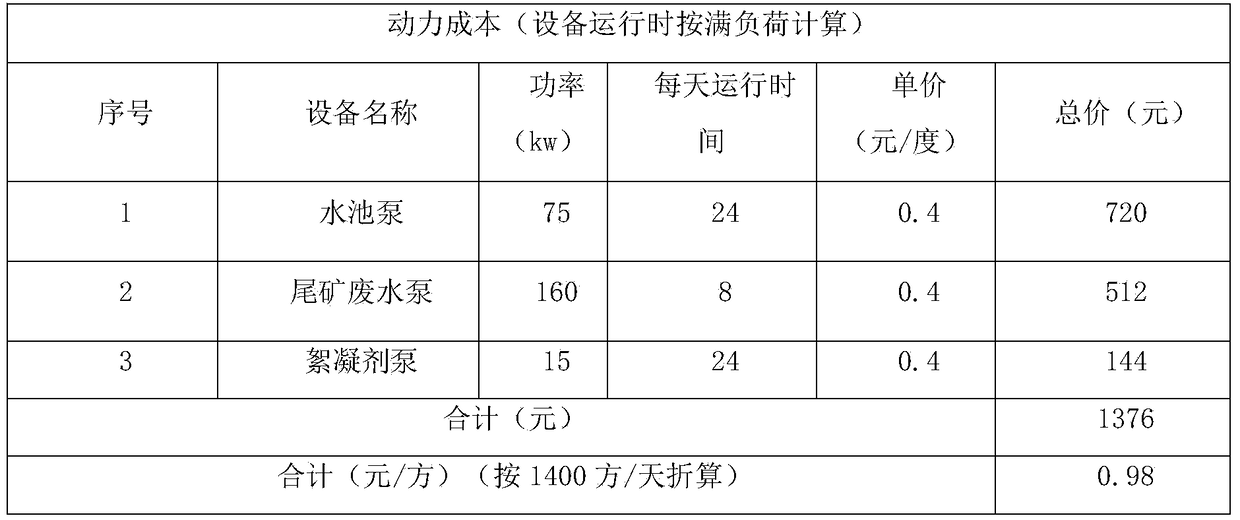

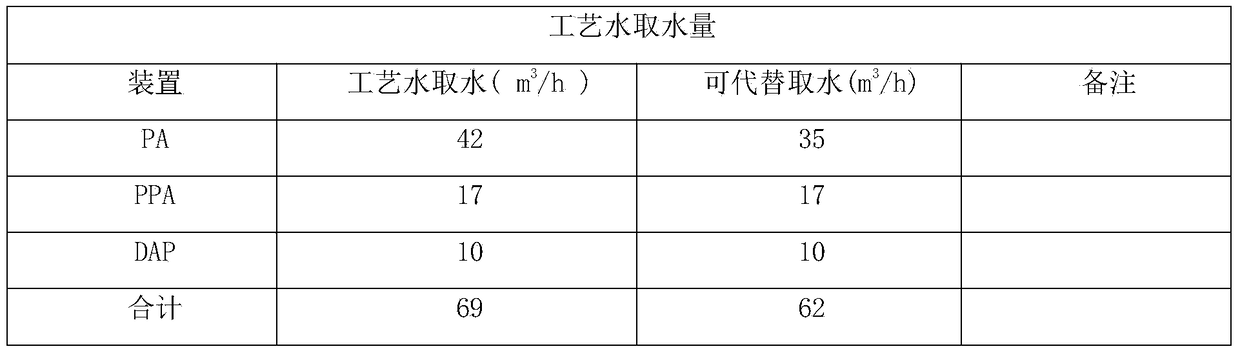

[0041] Example 2: In the present invention, the Lijiagou tailings backwater recycling system in Dazhou is taken as an example for evaluation.

[0042] 2.1 Overview of process flow

[0043] The working process of the tailings wastewater recycling system in the present invention is as follows:

[0044] In order to ensure the continuity of the water supply to the adjustment pool, first discharge the tailings wastewater into the reaction tank, and then into the thickener (volume 1450m 3 ), in which flocculant can be added according to the turbidity of the tailings wastewater. The impurities are rapidly flocculated under the action of the flocculant and deposited on the bottom of the thickener, and the upper liquid is relatively clear. The above-mentioned tailings wastewater after flocculation is quickly separated, wherein the lower flocculated impurities are pumped into the phosphoric acid reslurry tank in the solid collection unit through an underflow pump, and the upper liquid enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com