Device for soaking fireproof glass

A fire-resistant glass and box technology, which is applied in the field of glass surface treatment, can solve the problems of harming human health, etc., and achieve the effects of high automation level, fast air-drying process, and enlarged range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

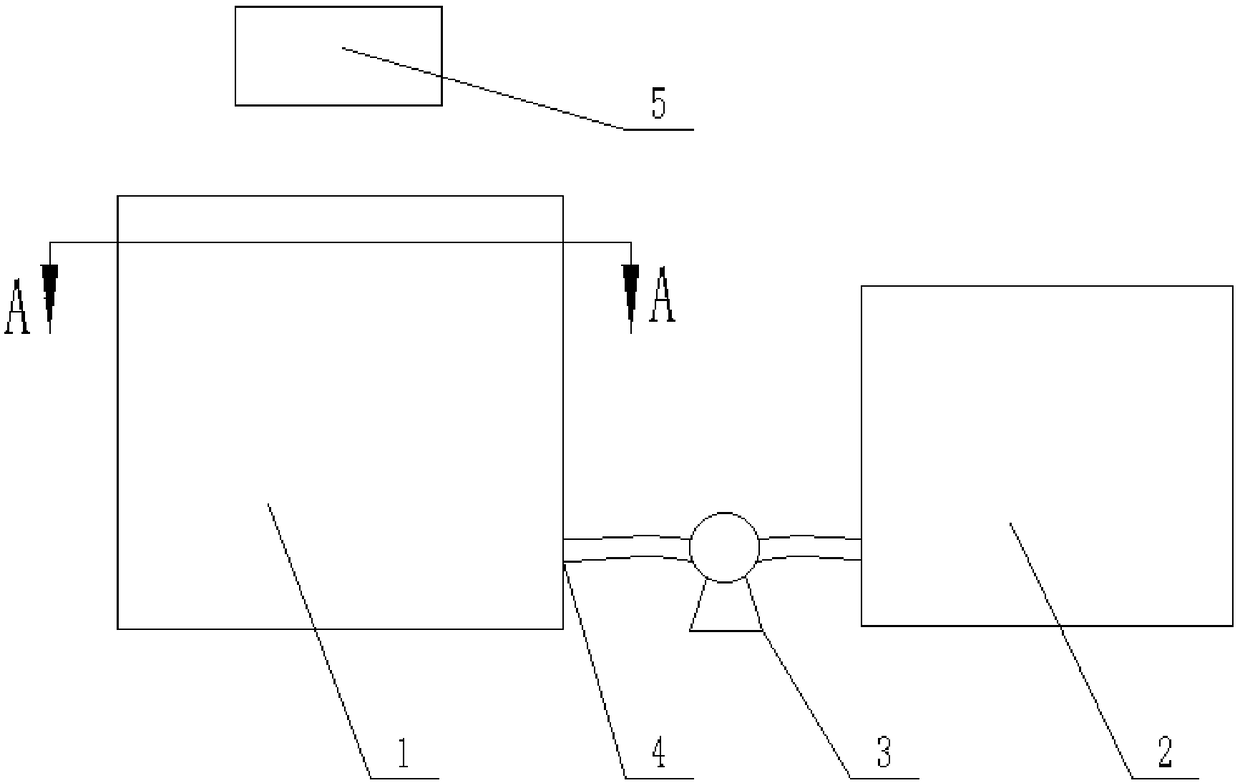

[0029] Fireproof glass immersion unit, including rack, if attached figure 1 As shown, the frame is equipped with a soaking tank 1, a water storage tank 2 and a water pump 3 between the two, and also includes an action mechanism installed on the bottom of the soaking tank 1, and is installed on the frame and is located at the soaking tank. The air-drying mechanism 5 above the casing 1. The soaking tank 1 and the water storage tank 2 communicate with the water pump 3 through the water pipe 4 . The air-drying mechanism 5 is horizontally slidably connected to the frame.

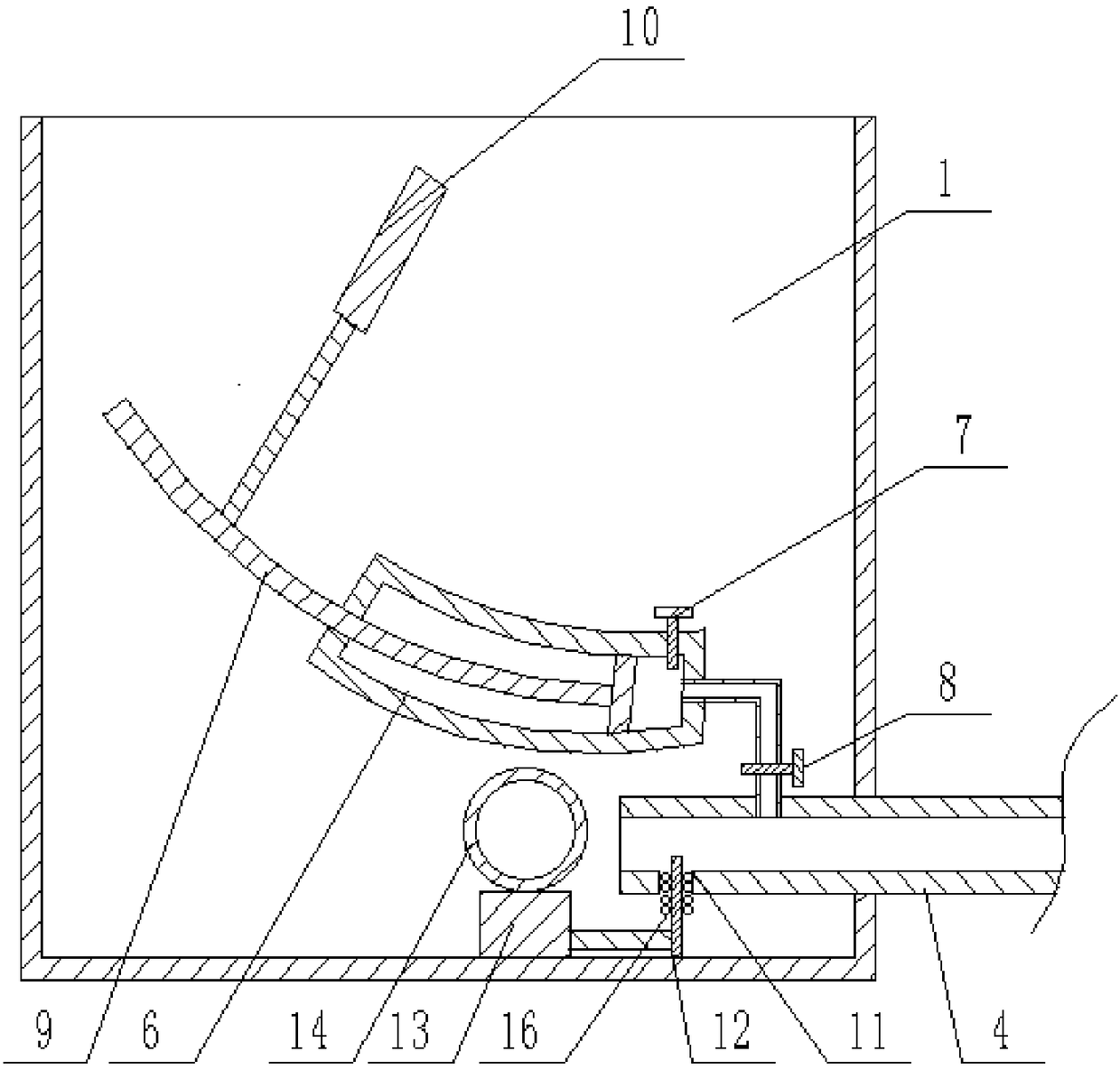

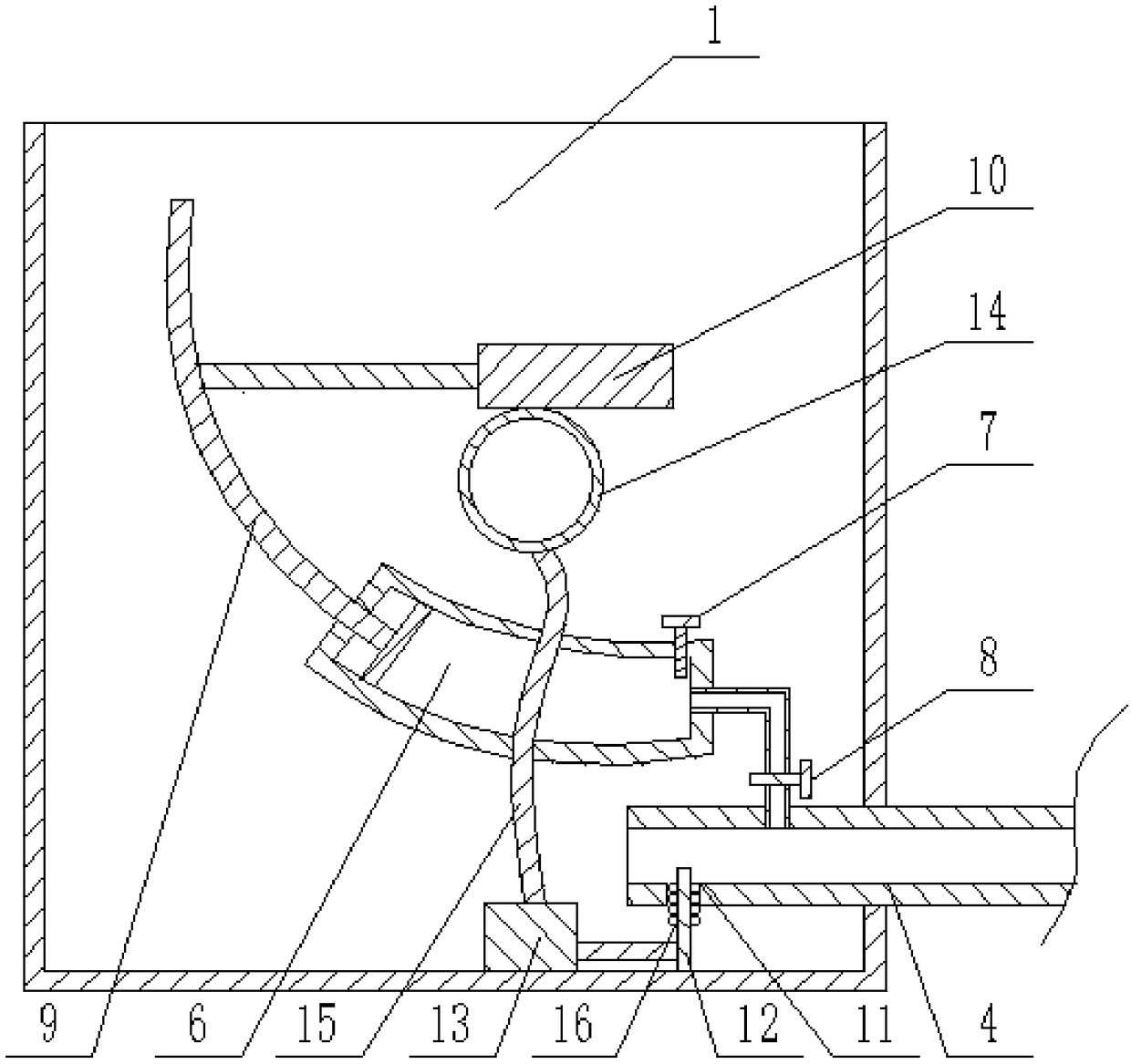

[0030] as attached figure 2 As shown, the action mechanism includes an arc cylinder 6 and a control mechanism installed below the arc cylinder 6 . The arc-shaped opening of the arc-shaped cylinder body 6 faces the opening of the soaking tank 1, and the rodless chamber of the arc-shaped cylinder body 6 is equipped with an electronically controlled throttle valve 7, and the rodless chamber of the arc-shaped cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com