Method of rapidly digesting brown algae to extract algin

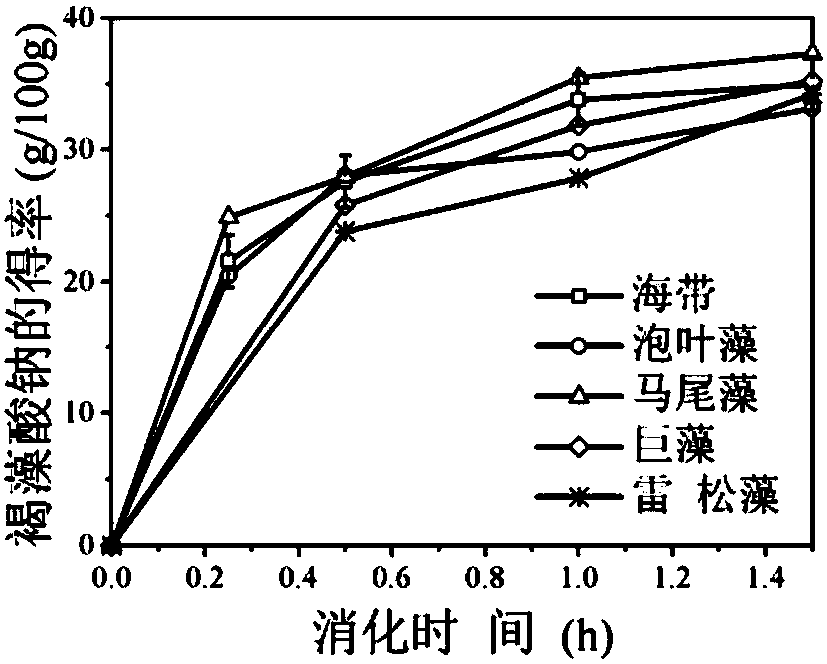

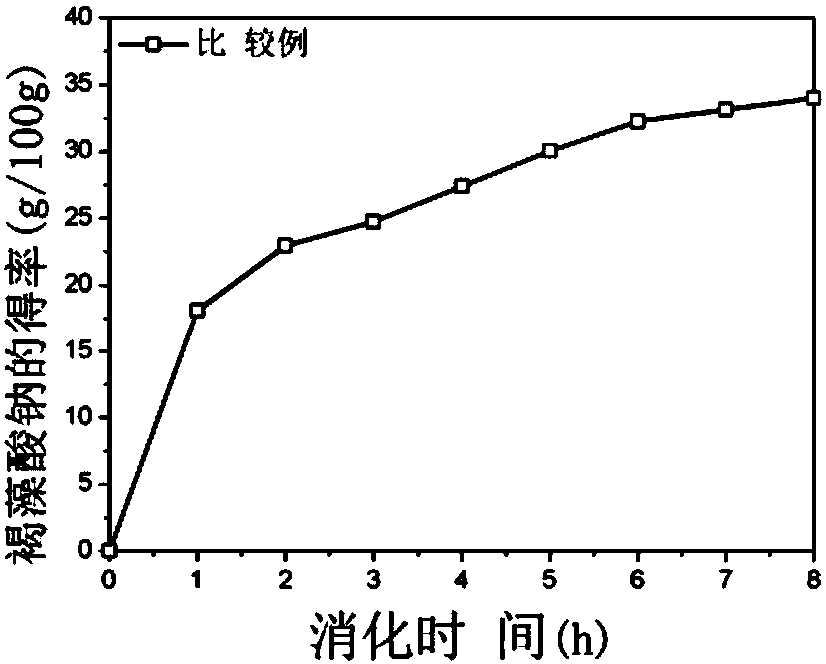

A technology for digesting brown algae and algin, which is applied in the field of rapidly digesting brown algae to extract high-viscosity algin, can solve the problems of long soaking and digesting time, prolonged production cycle and the like, and achieve the effects of shortening digestion time, shortening production time and improving product viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The alginate is extracted using the digestion process route of the present invention, and the raw material is Lessonia Trabeculata, which is produced in Chile and purchased from Runlin investment co., LTD.

[0033] (1) Grinding: Grinding 0.5 t of dry Rhizoma saponifera raw material (water content 15%) to the average sieve particle size d 50 = 1mm.

[0034] (2) Digestion: Add the crushed Leisong algae to the digestion pot, add 5m 3 (10 times the weight of dry algae) of hot water at 50±5°C, add 75kg (15% weight of dry algae) of sodium carbonate, stir continuously at 50°C, and digest for 0.5h to obtain a digestive juice.

[0035] The follow-up treatment of the obtained digestive juice refers to the existing process for the production of sodium alginate products, as follows: add tap water 100 times the weight of dry algae to the digestive juice, dilute it, and use an 18-mesh filter for coarse filtration; inject the filtrate into the floating tank for floating 3h, finely f...

Embodiment 2

[0037] The digestion process route of this technology is used to extract alginate, the others are the same as in Example 1, the difference is that the digestion temperature is 60°C, and finally 111kg of sodium alginate is obtained, with a yield of 22.2g / 100g brown algae and a viscosity of 1% sodium alginate aqueous solution It is 2250mPa·s.

Embodiment 3

[0039] The digestion process route of the present invention is used to extract alginate, the others are the same as in Example 2, except that the amount of alkali used is 40% of the weight of dry algae, and finally 123kg of sodium alginate is obtained, with a yield of 24.6g / 100g brown algae and 1% alginic acid The viscosity of the sodium aqueous solution is 2235 mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com