N-vinyl pyrrolidone and N-vinyl caprolactam random copolymer solution and preparation method thereof

A technology of vinylpyrrolidone and vinylcaprolactam, which is applied in the field of free radical solution polymerization, and can solve problems such as product safety impact and limited use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

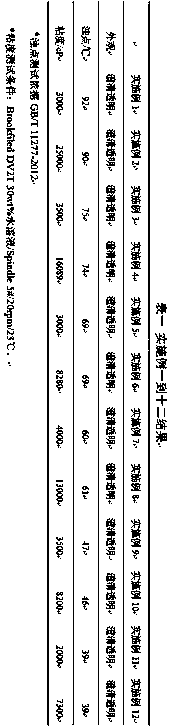

Image

Examples

Embodiment 1

[0038] Put 450 parts of ethanol, 18 parts of NVP, and 90 parts of NVCL into the reactor, slowly raise the temperature to 55°C under vigorous stirring, add 22.5 parts of azobisisobutyronitrile immediately after reaching the temperature, and start adding 342 parts of NVP. Dosing is completed within 8 hours. After that, 0.3 part of azobisisobutyronitrile was added and kept at a constant temperature for 5 hours, and the reaction was completed. Ethanol in the reaction solution was evaporated under reduced pressure using a rotary evaporator, and then 1800 parts of water was added for further evaporation to finally obtain a random copolymer solution with a solid content of 30 wt%.

Embodiment 2

[0040] Put 65 parts of water, 195 parts of ethanol, 18 parts of NVP, and 20 parts of NVCL into the reactor, slowly raise the temperature to 65°C under vigorous stirring, add 0.50 parts of azobisisobutyronitrile immediately after the temperature reaches, and start adding 78 parts of NVP, This part of NVP was added within 1.5 hours. After that, 0.06 part of azobisisobutyronitrile was added and kept at a constant temperature for 5 hours, and the reaction was completed. The water and ethanol in the reaction liquid were evaporated under reduced pressure using a rotary evaporator, and then 250 parts of water were added for further evaporation to finally obtain a random copolymer solution with a solid content of 30%.

Embodiment 3

[0042] Put 102 parts of water, 918 parts of isopropanol, 18 parts of NVP, and 160 parts of NVCL into the reactor, slowly raise the temperature to 60°C under vigorous stirring, add 0.50 parts of pivalate peroxide immediately after the temperature reaches, and start adding NVP162 Parts, this part of NVP is added within 1.0 hours. After that, 0.18 parts of peroxypivalic acid ester was added and kept at a constant temperature for 3 hours, and the reaction was completed. The water and isopropanol in the reaction solution were evaporated under reduced pressure using a rotary evaporator, and then 2000 parts of water were added for further evaporation to finally obtain a random copolymer solution with a solid content of 50 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com