Preparation method of polylactic acid/modified nanocellulose composite barrier material

A technology of nano-cellulose and barrier materials, which is applied in the field of preparation of polylactic acid/modified nano-cellulose degradable composite barrier materials, can solve problems such as unresolved dispersion, achieve good barrier properties and mechanical properties, and be cheap, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of polylactic acid / modified nanocellulose degradable composite barrier material, characterized in that it comprises the following steps:

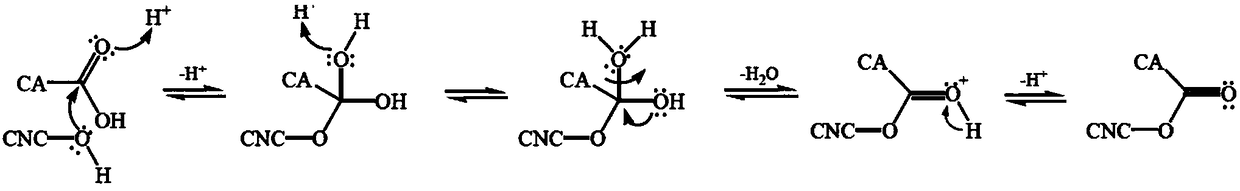

[0030] (1) Carboxylate modification of nanocellulose: prepare 8 wt% nanocellulose aqueous suspension, add nanocellulose aqueous suspension to the vacuum distillation reaction system, and add HCl to adjust the pH to 4.5. Add benzoic acid to the reaction system, and the molar ratio of benzoic acid to nanocellulose is 8:1. Insulate and react at 120°C for 20 hours. After the reaction, add ethanol at room temperature for homogeneous dispersion-centrifugal washing to obtain carboxylated modified nanocellulose, which is prepared as a modified nanocellulose suspension for use ; Finally, the carboxylic acid dissolved in the washing ethanol is recovered by a rotary evaporator to realize recycling.

[0031] (2) Preparation of polylactic acid / modified nanocellulose composite material by the Pickering emulsion method: add th...

Embodiment 2

[0034] A preparation method of polylactic acid / modified nanocellulose degradable composite barrier material, characterized in that it comprises the following steps:

[0035] (1) Carboxylate modification of nanocellulose: prepare 12wt% nanocellulose aqueous suspension, add nanocellulose aqueous suspension to the vacuum distillation reaction system, and add HCl to adjust the pH to 4.5. Add phenylpropionic acid to the reaction system, and the molar ratio of phenylpropionic acid to nanocellulose is 12:1. Insulate and react at 150°C for 25 hours. After the reaction, add ethanol at room temperature for homogeneous dispersion-centrifugal washing to obtain carboxylated modified nanocellulose, which is prepared as a modified nanocellulose suspension for use ; Finally, the carboxylic acid dissolved in the washing ethanol is recovered by a rotary evaporator to realize recycling.

[0036] (2) Preparation of polylactic acid / modified nanocellulose composite material by the Pickering emulsi...

Embodiment 3

[0039] A preparation method of polylactic acid / modified nanocellulose degradable composite barrier material, characterized in that it comprises the following steps:

[0040] (1) Carboxylate modification of nanocellulose: prepare 10% nanocellulose aqueous suspension, add nanocellulose aqueous suspension to the vacuum distillation reaction system, and add HCl to adjust the pH to 4.5. Add phenylacetic acid to the reaction system, wherein the molar ratio of phenylacetic acid to nanocellulose is 10:1. Insulate and react at 135°C for 22 hours. After the reaction, add ethanol at room temperature for homogeneous dispersion-centrifugal washing to obtain carboxylated modified nanocellulose, which is prepared as a modified nanocellulose suspension for use ; Finally, the carboxylic acid dissolved in the washing ethanol is recovered by a rotary evaporator to realize recycling.

[0041] (2) Preparation of polylactic acid / modified nanocellulose composite material by the Pickering emulsion m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com