Precision defocus detection device and method

A technology of defocus detection and detection method, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as low precision, complicated operating devices, and difficulty in meeting system requirements, and achieve low cost, high measurement accuracy, and dynamic The effect of a large measuring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

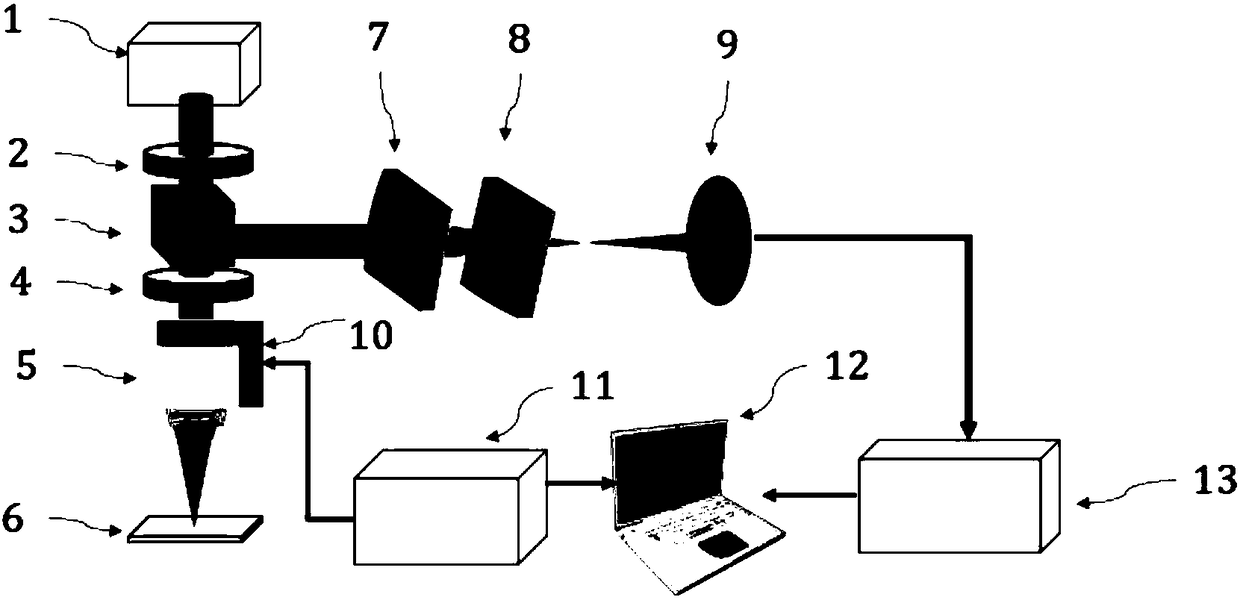

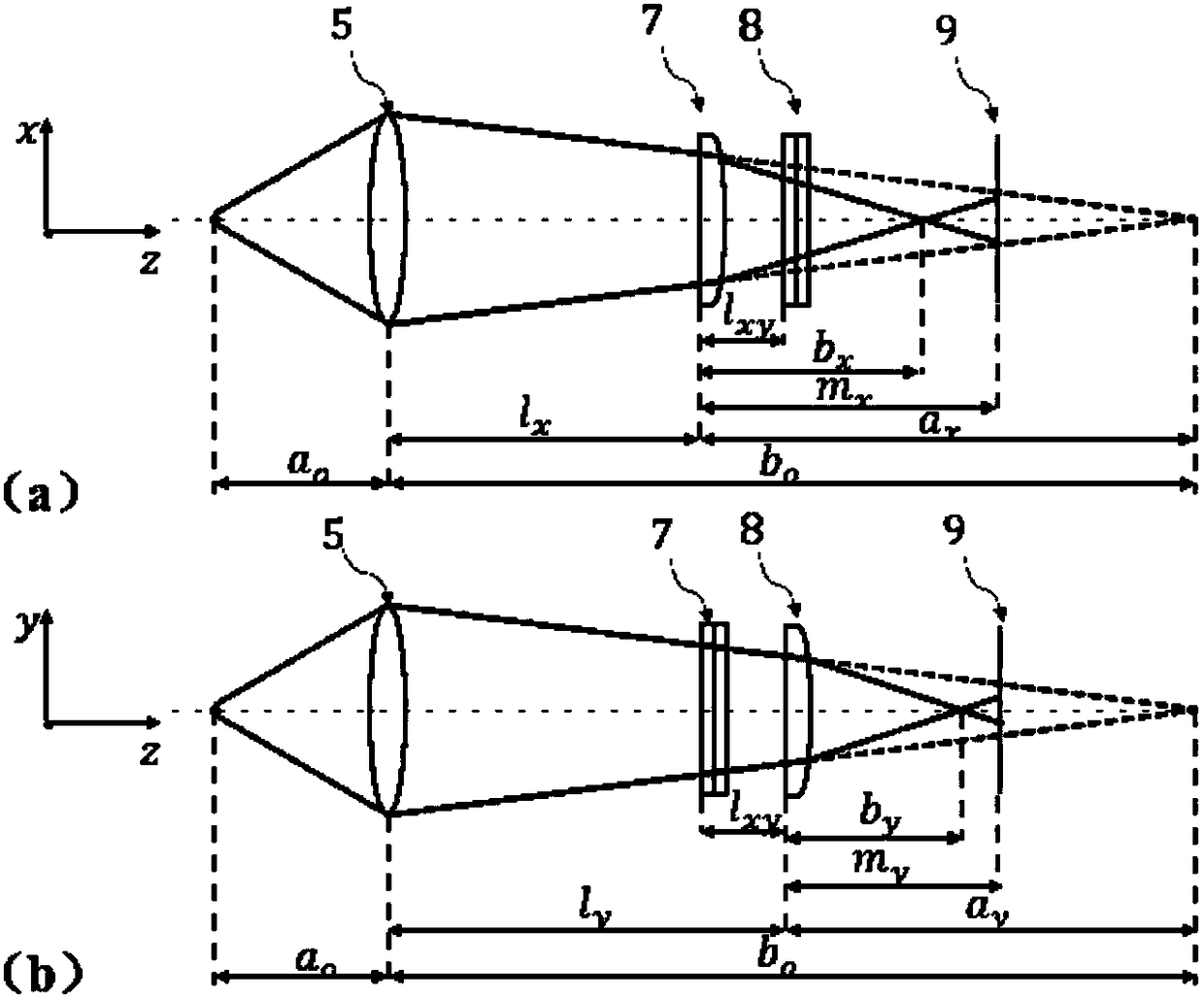

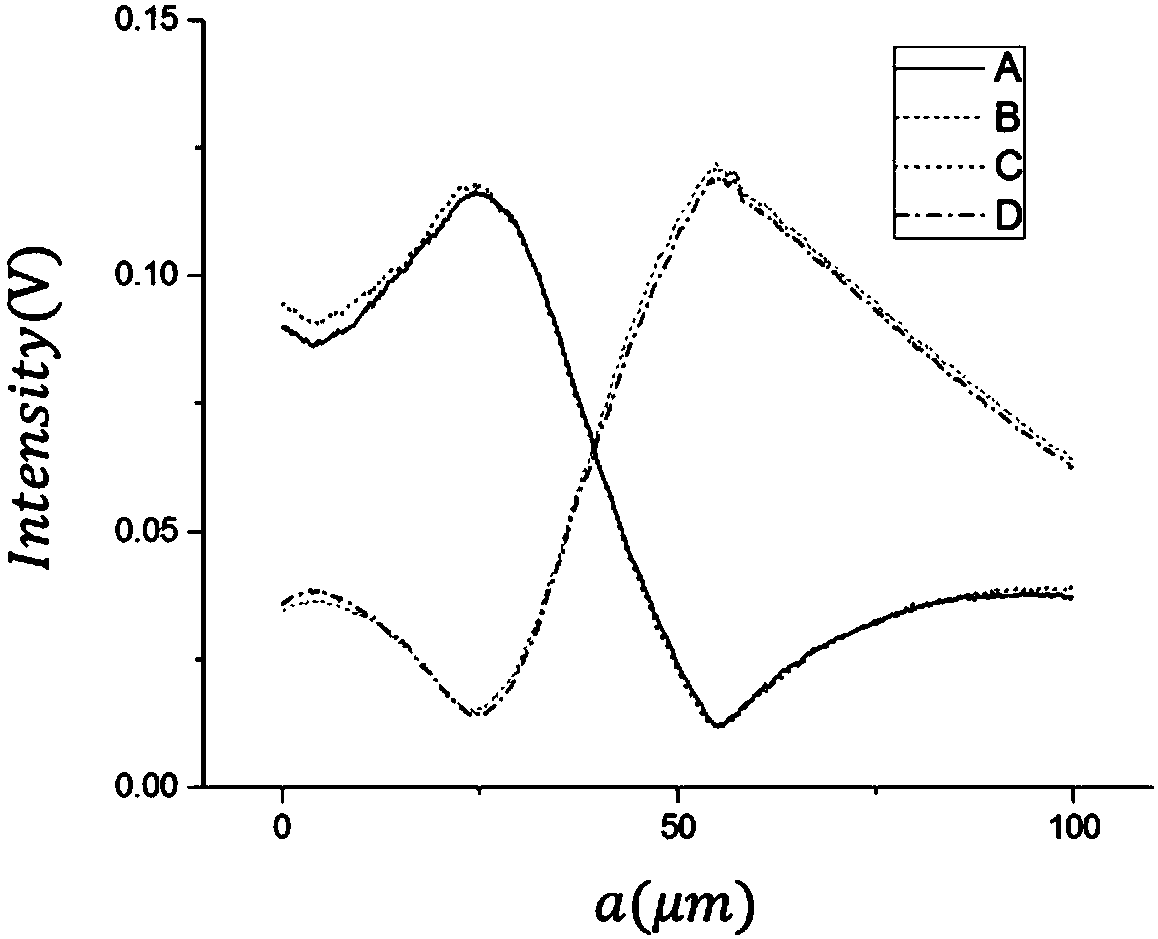

[0056] A new type of system defocus detection device and detection method, including a laser 1, a 1 / 2 wave plate 2, a polarization beam splitter prism 3, a 1 / 4 wave plate 4, a microscope objective lens 5, an aluminum film sample 6, and a cylindrical lens CL x 7. Cylindrical mirror CL y 8. Four-quadrant detector 9, piezoelectric ceramic actuator 10, piezoelectric ceramic controller 11, computer 12, controller 13, etc.: such as figure 1 As shown, the laser 1 emits parallel light with a wavelength of 658nm, then passes through the 1 / 2 wave plate 2, the polarization beam splitter 3, and the 1 / 4 wave plate 4, and then enters the microscope objective lens 5, and finally focuses on the aluminum film sample 6 . The laser light is reflected by the aluminum film sample 6, returns along the optical path, and then reflected by the polarizing beam splitter prism 3, and passes through the cylindrical mirror CL x 7 and cylindrical mirror CL x 8 are converged onto a four-quadrant detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com