Three-dimensional outline measuring method based on Structured Illumination Microscopy

A measurement method and three-dimensional contour technology, which is applied in the field of image recognition, can solve problems such as lack of information, distortion of three-dimensional contour edges, and limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0055] In order to achieve the purpose of the present invention, in some embodiments of a three-dimensional profile measurement method based on structured illumination microscopy, a three-dimensional profile measurement method based on structured illumination microscopy specifically includes the following steps:

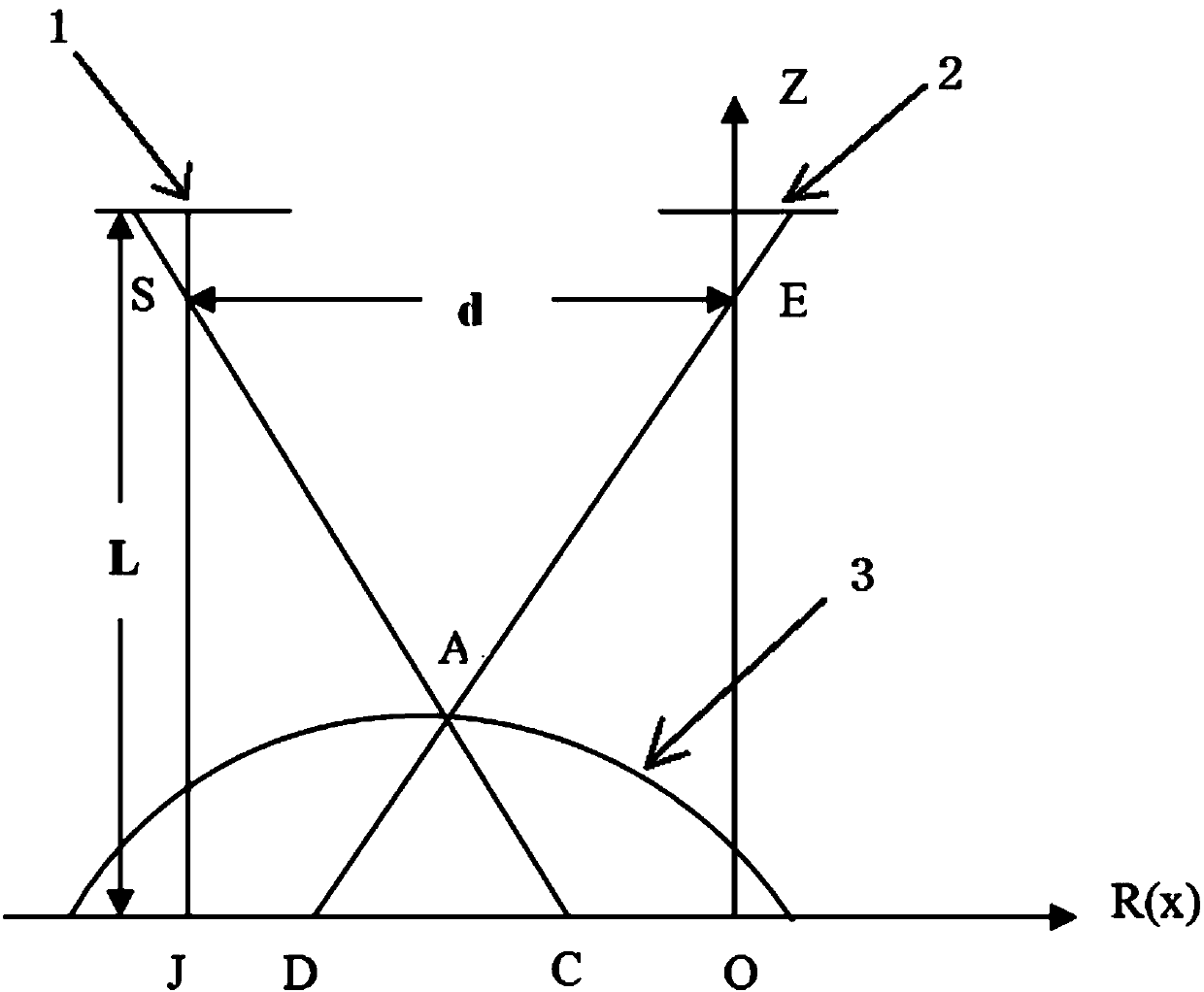

[0056]Step 1, using the three-dimensional surface shape measurement method to obtain the three-dimensional surface shape distribution point cloud data of the measured object;

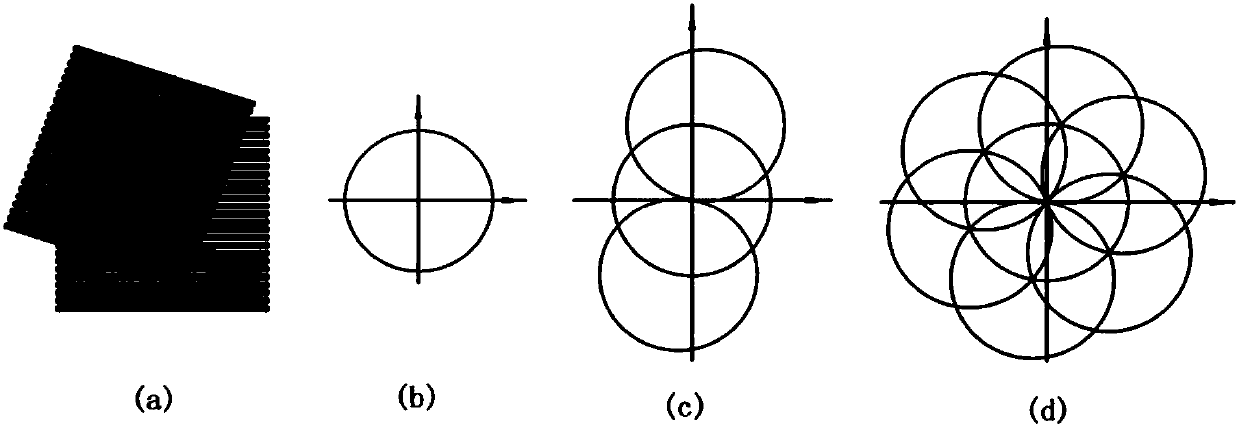

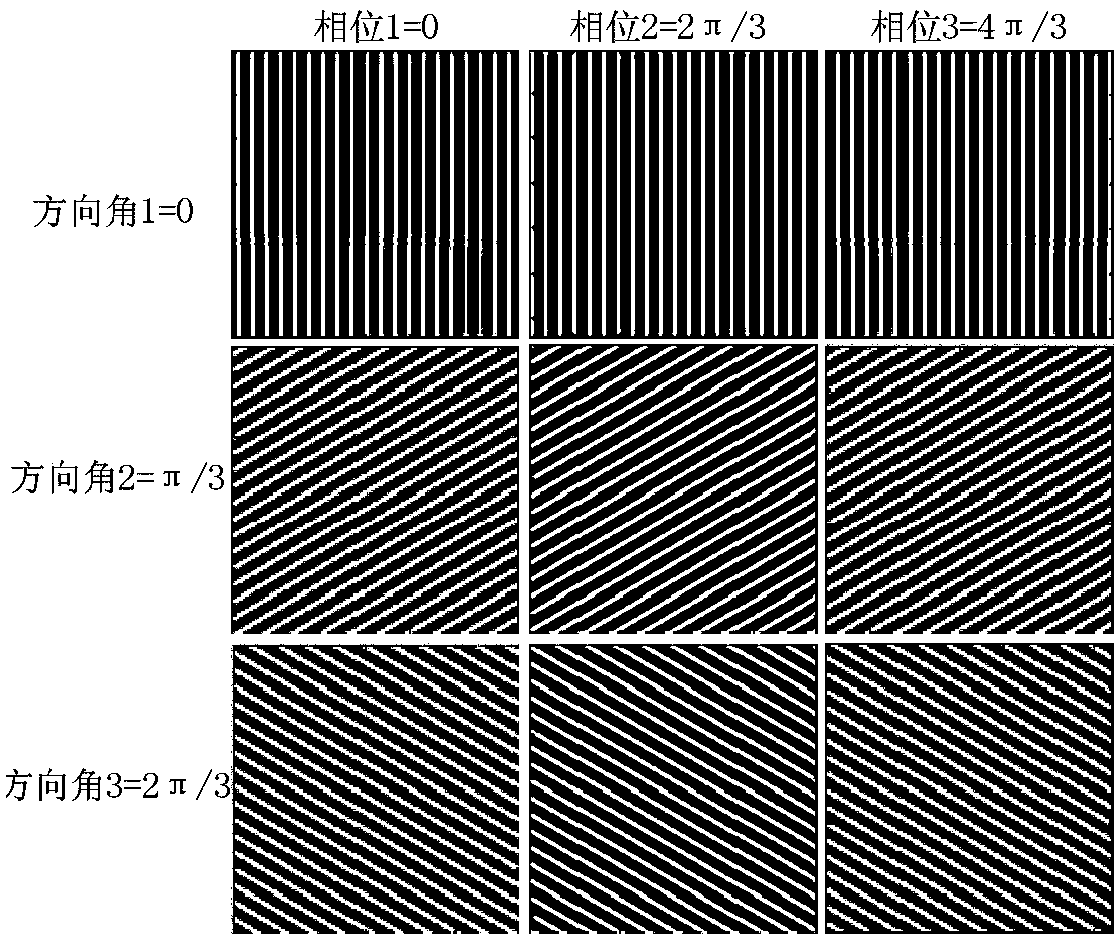

[0057] Step 2, using the structured light illumination method to obtain a two-dimensional plane image of the measured object;

[0058] Step 3, performing image processing on the two-dimensional planar image obtained in step 2 to obtain the super-resolution edge profile of the measured object;

[0059] In step four, the 3D surface distribution point cloud dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com