Preliminary screening system for COD (chemical oxygen demand ) automatic test

An automated testing and reagent bottle technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of high testing cost, insufficient environmental protection, a large number of toxic and harmful reagents, etc., to reduce the probability of contact, save testing costs, and reduce the use of precious metals. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

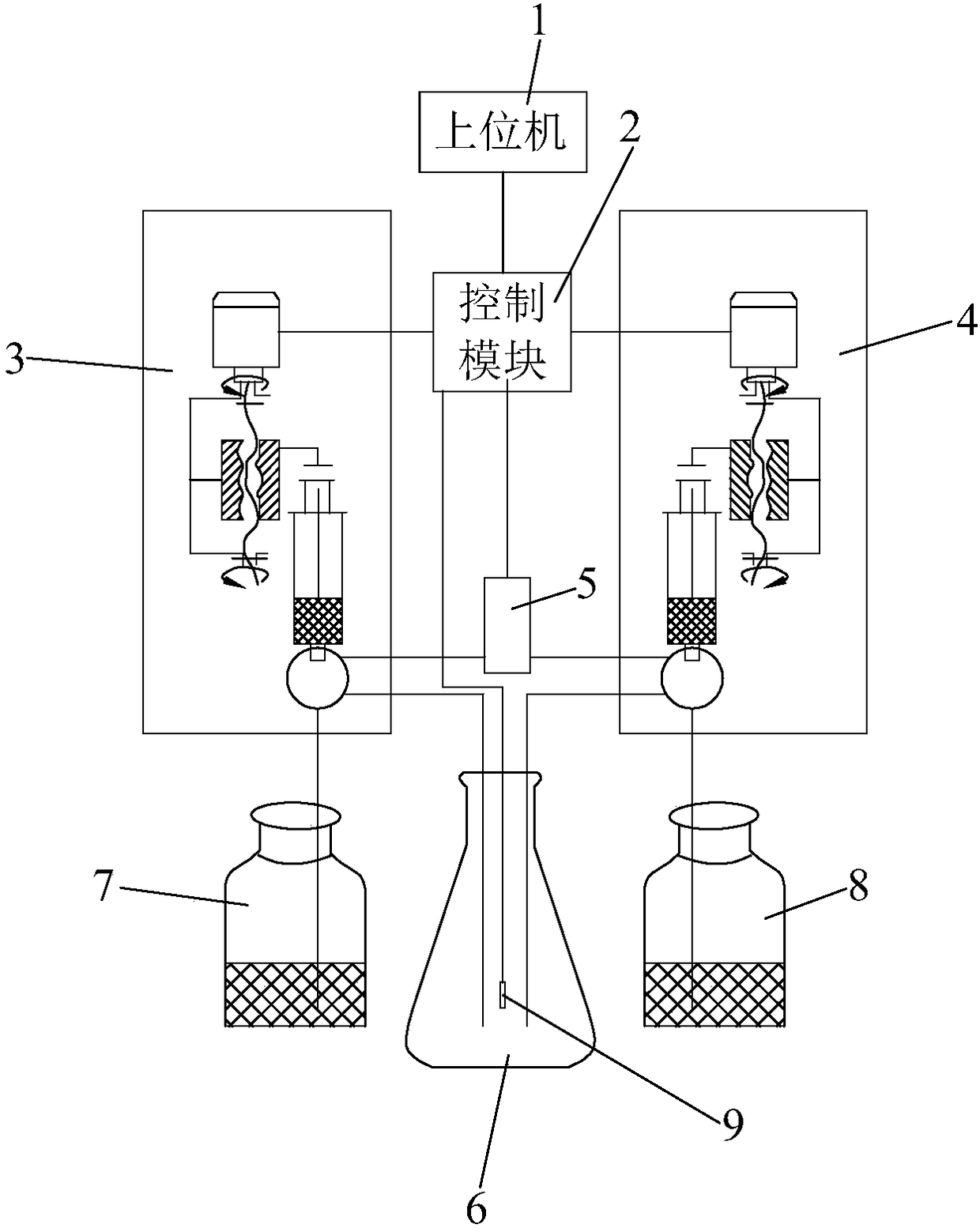

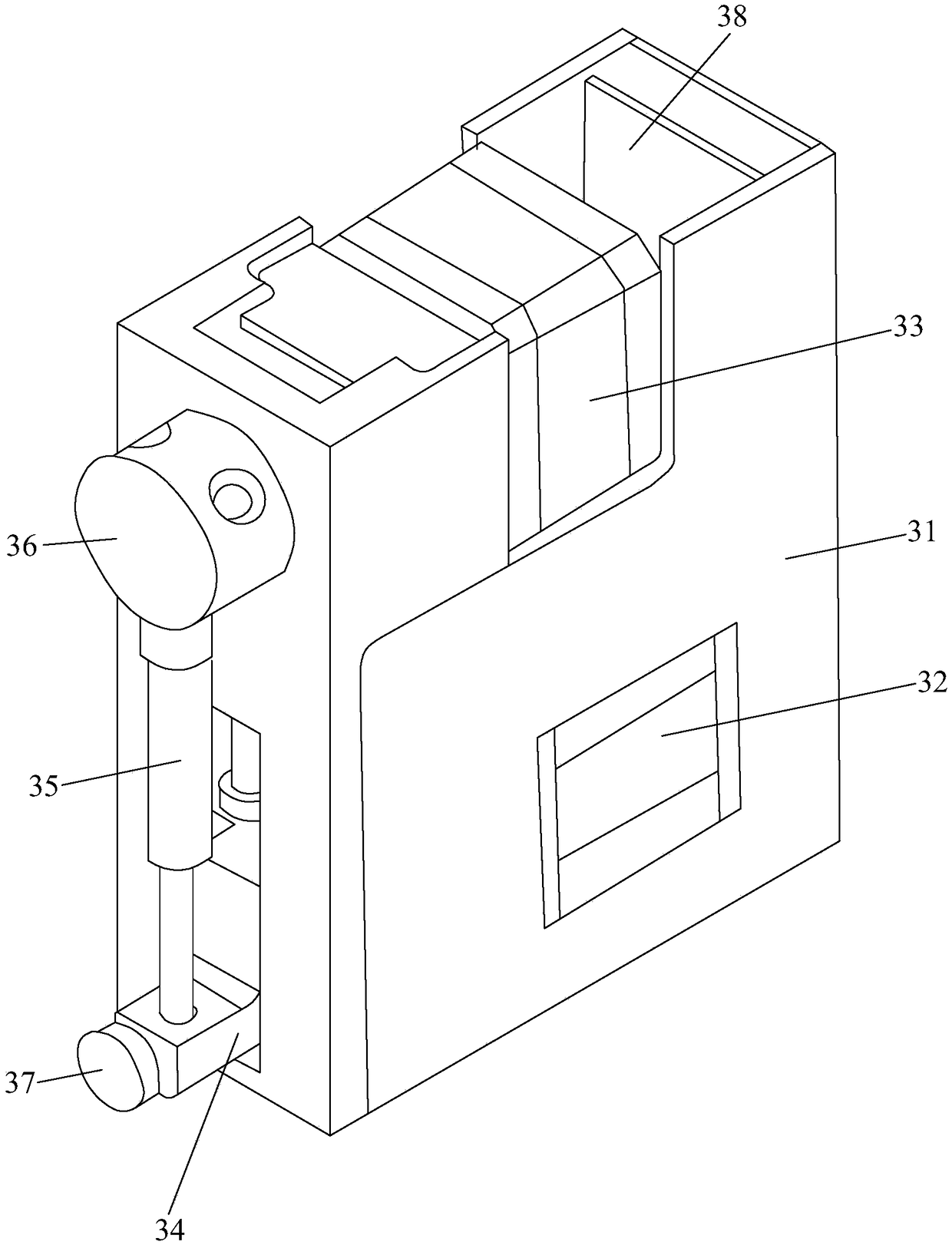

[0026] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, such as figure 1 and 2 As shown, the COD primary screening system provided by the embodiments of the present invention includes:

[0027] Host computer 1;

[0028] The first syringe pump mechanism 3, the first syringe pump mechanism 3 is used to receive the control signal sent by the control module to take an appropriate amount of sample and react with the primary screening reagent;

[0029] Spectrophotometer 5, used to test the absorbance value;

[0030] Reagent bottle 7 is used to store the preliminary screening reagent, which is potassium dichromate solution and sulfuric acid;

[0031] Chloride ion selective electrode 9, described chloride ion selective electrode is used for testing the voltage information in sample bottle 6 and transmits to described control module;

[0032] Control module 2, sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com