Frequency dividing detector for feedback control of low frequency electromagnetic vibration table system

An electromagnetic vibration and feedback control technology, applied in electric controllers, using electromagnetic means, controllers with specific characteristics, etc. The difficulty of parameter adjustment, the improvement of precision, and the effect of simplifying the speed detection device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

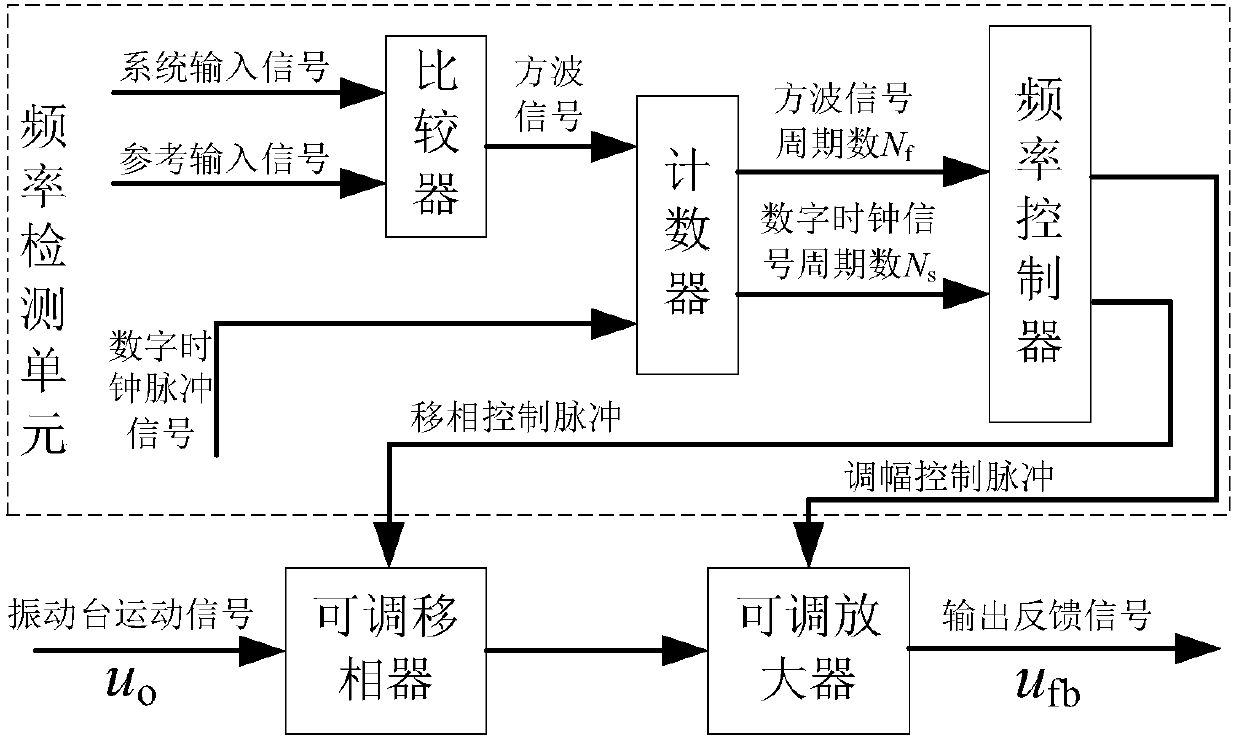

[0038] Such as figure 1 As shown, the frequency division detector is used for the feedback control of the low-frequency electromagnetic vibrating table system. The frequency division detector is composed of a comparator, a counter and a frequency controller connected in sequence. The system input signal and the reference input signal are jointly input to the comparator. The comparator Output the square wave signal formed by the input signal of the vibration table system and the reference input signal, the square wave signal and the digital clock pulse signal are input into the counter together, and the counter outputs the number of cycles of the system input signal N f and the number of cycles of the digital clock pulse signal N s , the frequency controller calculates and obtains the frequency value ff of the square wave signal, where f s Indicates the frequency value of the digital clock pulse signal; the frequency of the square wave signal corresponds to the current worki...

Embodiment 2

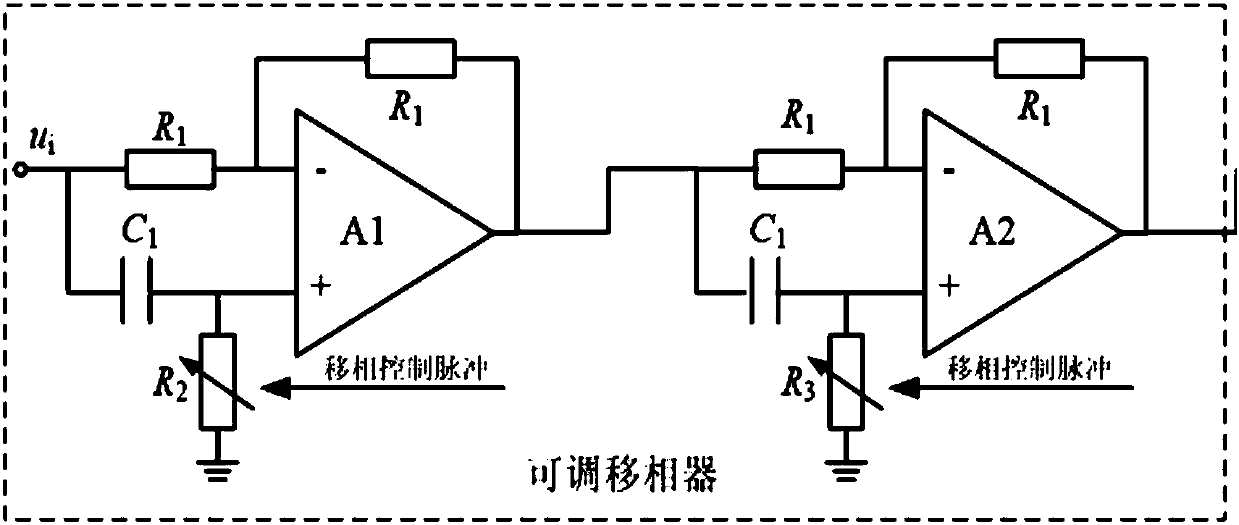

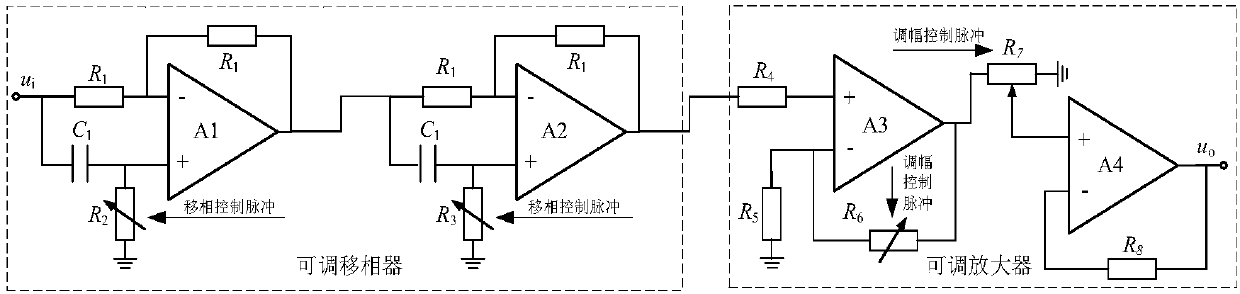

[0057] see figure 1 , figure 2 , in embodiment 1, based on the low-frequency electromagnetic vibrating table system of induction coil feedback control, the low-frequency electromagnetic vibrating table system includes a signal generator, a speed feedback control device, a power amplifier and a low-frequency electromagnetic vibrating table; the moving coil of the low-frequency vibrating table has drive coil and induction coil.

[0058] The driving coil and the induction coil are wound together in the same winding slot of the moving part 1 of the vibrating table, or the induction coil and the driving coil can be wound side by side in different winding slots of the moving part of the vibrating table, and the induction coil and the driving coil can be ensured. The coils are coaxial and in a uniform air-gap magnetic field. The speed feedback control device includes a feedback part and a control part, the induced voltage of the induction coil is input to the feedback part, the sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com