Conductive Cu/PDA/PVDF composite ultrafiltration membrane and preparation method thereof

An ultrafiltration membrane, self-polymerization technology, applied in ultrafiltration, chemical instruments and methods, membranes, etc., to achieve the effect of low Cu loss rate, good hydrophilicity, and excellent anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

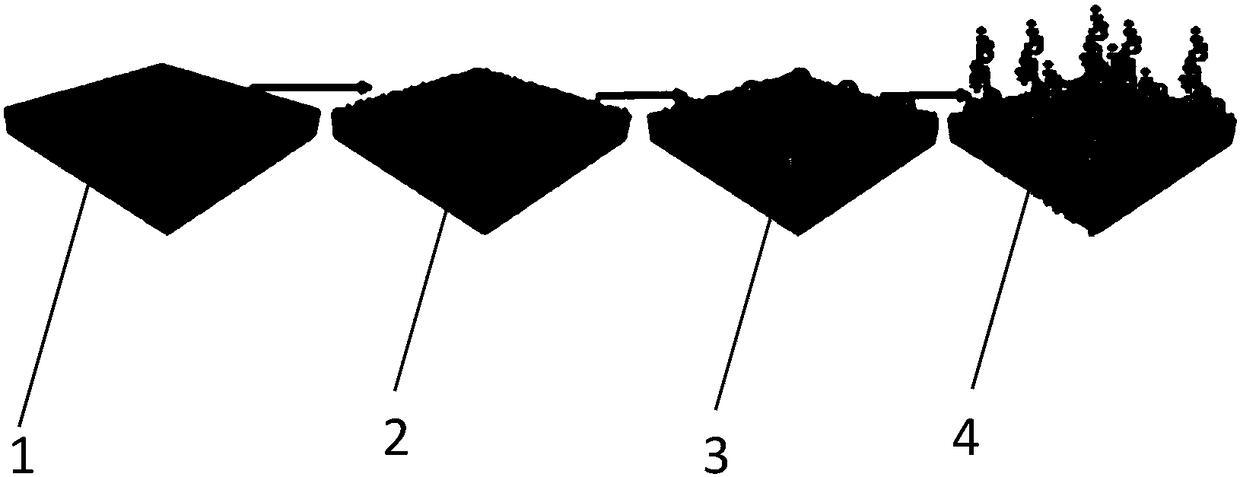

[0044] A preparation method of conductive Cu / PDA / PVDF composite ultrafiltration membrane, the preparation method includes the following steps:

[0045] S1: Cleaning the PVDF ultrafiltration membrane; the cleaning is first cleaning with deionized water and ultrasonic cleaning in ethanol;

[0046] S2: The PVDF ultrafiltration membrane is modified by dopamine (PDA), specifically, the cleaned PVDF ultrafiltration membrane is immersed in a dopamine (PDA) solution and tris-HCl buffer solution In the container, the container is then placed in a shaking water bath to make dopamine self-polymerize on the surface of the ultrafiltration membrane; wherein the concentration of dopamine is 2.0 mg / mL, the pH value is 8.5, and the tris The concentration of HCl) buffer is 50 mM; the self-polymerization time in a shaking water bath is 24 hours.

[0047] S3: cleaning the PVDF ultrafiltration membrane modified in step S2, and the cleaning is 12 hours with deionized water and ethanol to obtain a PDA / PVD...

Embodiment 2

[0052] A preparation method of conductive Cu / PDA / PVDF composite ultrafiltration membrane, the preparation method includes the following steps:

[0053] S1: Cleaning the PVDF ultrafiltration membrane; the cleaning is first cleaning with deionized water and ultrasonic cleaning in ethanol;

[0054] S2: The PVDF ultrafiltration membrane is modified by dopamine (PDA), specifically, the cleaned PVDF ultrafiltration membrane is immersed in a dopamine (PDA) solution and tris-HCl buffer solution In the container, the container is then placed in a shaking water bath to make dopamine self-polymerize on the surface of the ultrafiltration membrane; wherein the concentration of dopamine is 2.0 mg / mL, the pH value is 8.5, and the tris -HCl) The concentration of the buffer is 50mM; the self-polymerization time in the shaking water bath is 24 hours;

[0055] S3: cleaning the PVDF ultrafiltration membrane modified in step S2, and the cleaning is 12 hours with deionized water and ethanol to obtain a P...

Embodiment 3

[0060] A preparation method of conductive Cu / PDA / PVDF composite ultrafiltration membrane, the preparation method includes the following steps:

[0061] S1: Cleaning the PVDF ultrafiltration membrane; the cleaning is first cleaning with deionized water and ultrasonic cleaning in ethanol;

[0062] S2: The PVDF ultrafiltration membrane is modified by dopamine (PDA), specifically, the cleaned PVDF ultrafiltration membrane is immersed in a dopamine (PDA) solution and tris-HCl buffer solution In the container, the container is then placed in a shaking water bath to make dopamine self-polymerize on the surface of the ultrafiltration membrane; wherein the concentration of dopamine is 2.0 mg / mL, the pH value is 8.5, and the tris -HCl) The concentration of the buffer is 50mM; the self-polymerization time in the shaking water bath is 24 hours;

[0063] S3: cleaning the PVDF ultrafiltration membrane modified in step S2, and the cleaning is 12 hours with deionized water and ethanol to obtain a P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com