Chlorine water dechlorinating system and use method thereof

A chlorinated water and dechlorination technology, applied in chemical instruments and methods, water pollutants, multi-stage water treatment, etc., can solve problems such as corrosion of sewers, low dark holes, metal corrosion, etc., to increase the proportion of halogen used, reduce Lower production cost and better effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

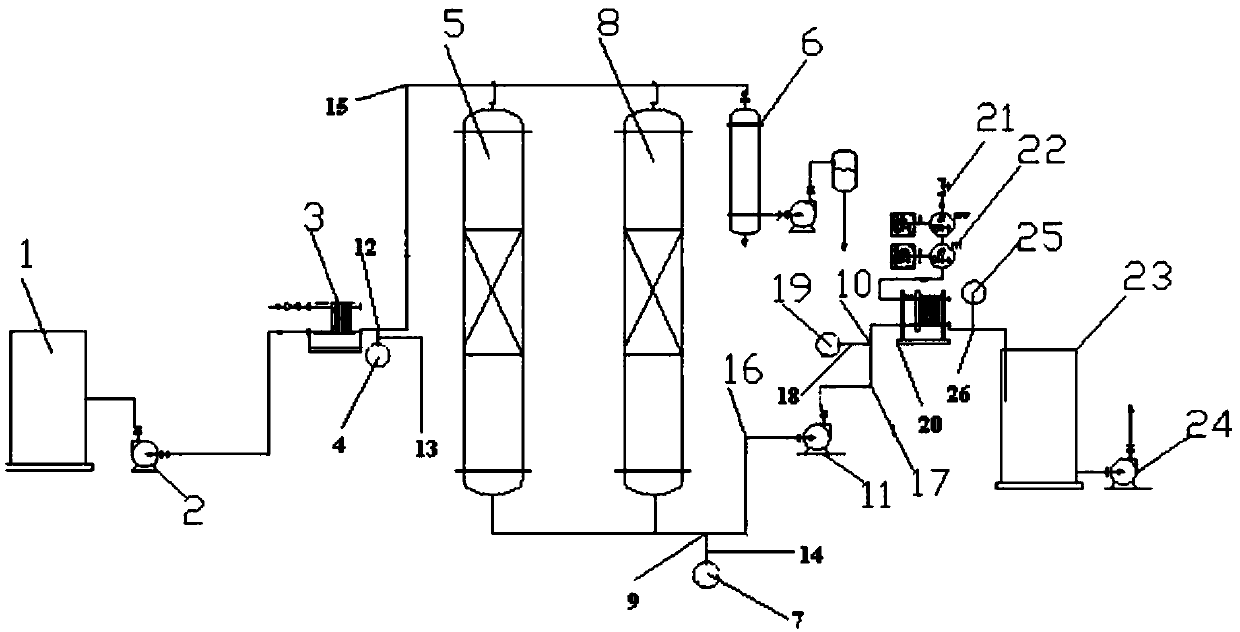

[0032] A method for using a chlorinated water dechlorination system comprises the steps of:

[0033] Step 1: Chlorine water pump I2 pressurizes the chlorine water in the chlorine water tank 1 to the chlorine water heater 3 and heats it to 84°C, then adds hydrochloric acid through the hydrochloric acid inlet nozzle 12 and controls the inlet through the hydrochloric acid flow regulating valve 4 Add acid to chlorine water to adjust pH to 1.5;

[0034]Step 2: the chlorine water is delivered to the chlorine water dechlorination tower I5 and the chlorine water dechlorination tower II8 for dechlorination treatment, and the dechlorination tower liquid level controller 26 controls the level of the chlorine water dechlorination tower II8 and the chlorine water dechlorination tower I5 The liquid level is equal and the distance between the liquid level and the top of the tower is controlled to be 0.6m, and the evaporated chlorine and water vapor are absorbed by the top of the tower and co...

Embodiment 2

[0041] A method for using a chlorinated water dechlorination system comprises the steps of:

[0042] Step 1: Chlorine water pump I2 pressurizes the chlorine water in the chlorine water tank 1 to the chlorine water heater 3 and heats it to 85°C, then adds hydrochloric acid through the hydrochloric acid inlet nozzle 12 and controls the inlet through the hydrochloric acid flow regulating valve 4 Adjust the pH to 1.65 by adding acid to the tower chlorine water;

[0043] Step 2: the chlorine water is delivered to the chlorine water dechlorination tower I5 and the chlorine water dechlorination tower II8 for dechlorination treatment, and the dechlorination tower liquid level controller 26 controls the level of the chlorine water dechlorination tower II8 and the chlorine water dechlorination tower I5 The liquid level is equal and the distance between the liquid level and the top of the tower is controlled to be 0.7m, and the evaporated chlorine and water vapor are absorbed by the top ...

Embodiment 3

[0050] A method for using a chlorinated water dechlorination system comprises the steps of:

[0051] Step 1: Chlorine water pump I2 pressurizes the chlorine water in the chlorine water tank 1 to the chlorine water heater 3 and heats it to 86°C, then adds hydrochloric acid through the hydrochloric acid inlet nozzle 12 and controls the inlet through the hydrochloric acid flow regulating valve 4 Adjust the pH to 1.8 by adding acid to the tower chlorine water;

[0052] Step 2: the chlorine water is delivered to the chlorine water dechlorination tower I5 and the chlorine water dechlorination tower II8 for dechlorination treatment, and the dechlorination tower liquid level controller 26 controls the level of the chlorine water dechlorination tower II8 and the chlorine water dechlorination tower I5 The liquid level is equal and the distance between the liquid level and the top of the tower is controlled to be 0.8m, and the evaporated chlorine and water vapor are absorbed by the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com