Method for catalytically preparing 2,6-dimethylnaphthalene

A technology for the preparation of dimethylnaphthalene and catalysis, which is applied in the field of catalysis and can solve problems such as high yield of 2,6-dimethylnaphthalene, difficulty in product separation, complex process, etc., and achieve less catalyst usage and high reaction stability , high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

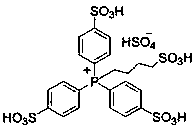

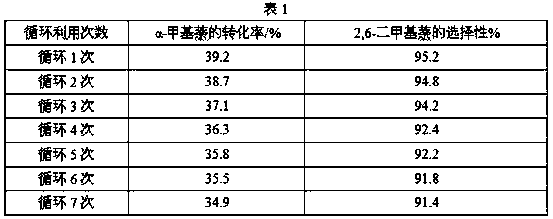

[0031] A method for the catalytic preparation of 2,6-dimethylnaphthalene is to add a mixed solution obtained by mixing α-methylnaphthalene and mesitylene in a molar ratio of 1:10 into a stirred ultrasonic reactor , Stir the reaction for 45 min under an inert atmosphere, and then add a magnetic ionic liquid catalyst at 40℃, N 2 Under the conditions of inert atmosphere, stirring speed of 400r / min and ultrasonic power of 240W, react for 50min, and let stand for 30min after the reaction is completed; the catalyst in the lower layer is directly recycled after being separated by a magnetic field; the upper layer contains a mixture of 2,6-dimethylnaphthalene After further separation and purification, 2,6-dimethylnaphthalene product and unreacted raw materials were obtained; and the content of each component was analyzed by gas chromatography. After analysis, the conversion rate of α-methylnaphthalene was 41.7%, 2 The selectivity of 6-dimethylnaphthalene is 94.2%.

[0032] The preparatio...

Embodiment 2

[0045] A method for the catalytic preparation of 2,6-dimethylnaphthalene is to add a mixed solution obtained by mixing β-methylnaphthalene and mesitylene in a molar ratio of 1:20 into a stirred ultrasonic reactor , Stir the reaction under an inert atmosphere for 35 minutes, then add a strong acidic ionic liquid, react for 80 minutes at 25℃, Ar inert atmosphere, stirring speed of 600r / min, and ultrasonic power of 150W for 80 minutes, and let stand for 30 minutes after the reaction is complete; The liquid is directly recycled after being separated by a magnetic field; the upper layer contains 2,6-dimethylnaphthalene-containing mixed liquid for further separation and purification to obtain 2,6-dimethylnaphthalene product and unreacted raw materials; and analyze each group by gas chromatography According to the analysis, the conversion rate of β-methylnaphthalene was 38.7%, and the selectivity of 2,6-dimethylnaphthalene was 95.4%.

[0046] Among them, the preparation steps of the mag...

Embodiment 3

[0048] A method for the catalytic preparation of 2,6-dimethylnaphthalene is to add α-methylnaphthalene, β-methylnaphthalene and mesitylene into a stirred ultrasonic reactor in a molar ratio of 1:1: 20. Mix the resulting mixed solution, stir and react under an inert atmosphere for 40 minutes, then add the magnetic ionic liquid, and react for 15 minutes at 35°C, He inert atmosphere, stirring speed of 500r / min, and ultrasonic power of 300W for 15 minutes. Let it stand for 30 minutes; the lower ionic liquid is directly recycled after being separated by a magnetic field; the upper layer contains 2,6-dimethylnaphthalene-containing mixed liquid for further separation and purification to obtain 2,6-dimethylnaphthalene product and unreacted raw materials; among them, The content of each component was analyzed by gas chromatography. After analysis, the conversion rate of methyl naphthalene was 45.7%, and the selectivity of 2,6-dimethyl naphthalene was 89.5%.

[0049] Among them, the prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com