Easily crystallizable furan-based polyester composition and preparation method thereof

A technology of furyl polyester and its manufacturing method, which is applied in the field of polymer materials and furyl polyester materials, can solve the problems of strong odor and restricting the normal application of resin, etc., achieve high melting temperature, easy industrialization, and good compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

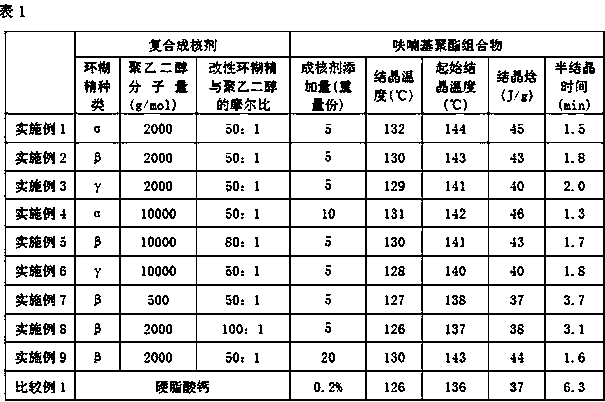

Examples

Embodiment 1

[0038] Add 200ml of phosphate buffer solution with a pH of 7 to a 250ml three-neck flask, then add polyvinylpolyamine and carboxymethyl-α-cyclodextrin into the flask at a molar ratio of 3:1, and react in a mixed ice-water bath After 24 hours, the modified cyclodextrin was precipitated with acetone as a solvent, and dried under vacuum at 100°C.

[0039] Completely dissolve 1 mol of cyclodextrin modified by polyethylene polyamine in 300ml of 50% ethanol / water solution, then make the molar ratio of cyclodextrin and polyethylene glycol 50:1, add polyethylene glycol 2000 and stir at 70°C After reacting for 16 hours, slowly cool down to room temperature, let it stand still, filter and wash after a large amount of precipitates appear, and vacuum dry to obtain the target product—polyethylene polyamine modified cyclodextrin and polyethylene glycol clathrate.

[0040] First dry 100 parts by weight of polyethylene 2,5 furandicarboxylate at 150°C for 8 hours, and set aside; then dry the p...

Embodiment 2

[0042]Add 200ml of phosphate buffer solution with a pH of 7 to a 250ml three-neck flask, then add polyvinylpolyamine and carboxymethyl-β-cyclodextrin into the flask at a molar ratio of 3:1, and react in a mixed ice-water bath After 24 hours, the modified cyclodextrin was precipitated with acetone as a solvent, and dried under vacuum at 100°C.

[0043] Completely dissolve 1 mol of cyclodextrin modified by polyethylene polyamine in 300ml of 50% ethanol / water solution, then make the molar ratio of cyclodextrin and polyethylene glycol 50:1, add polyethylene glycol 2000 and stir at 70°C After reacting for 16 hours, slowly cool down to room temperature, let it stand still, filter and wash after a large amount of precipitates appear, and vacuum dry to obtain the target product—polyethylene polyamine modified cyclodextrin and polyethylene glycol clathrate.

[0044] First dry 100 parts by weight of polyethylene 2,5 furandicarboxylate at 150°C for 8 hours, and set aside; then dry the po...

Embodiment 3

[0046] Add 200ml of phosphate buffer solution with a pH of 7 to a 250ml three-neck flask, then add polyvinylpolyamine and carboxymethyl-γ-cyclodextrin into the flask at a molar ratio of 3:1, and react in an ice-water mixing bath After 24 hours, the modified cyclodextrin was precipitated with acetone as a solvent, and dried under vacuum at 100°C.

[0047] Completely dissolve 1 mol of cyclodextrin modified by polyethylene polyamine in 300ml of 50% ethanol / water solution, then make the molar ratio of cyclodextrin and polyethylene glycol 50:1, add polyethylene glycol 2000 and stir at 70°C After reacting for 16 hours, slowly cool down to room temperature, let it stand still, filter and wash after a large amount of precipitates appear, and vacuum dry to obtain the target product—polyethylene polyamine modified cyclodextrin and polyethylene glycol clathrate.

[0048] First dry 100 parts by weight of polyethylene 2,5 furandicarboxylate at 150°C for 8 hours, and set aside; then dry the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com