Manufacturing process of warm-keeping waterproof fabric

A technology of waterproof fabric and production process, which is applied in the field of fabric, can solve the problems of backward production process of warm and waterproof fabric, and achieve the effects of saving manpower, high production efficiency and uniform dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

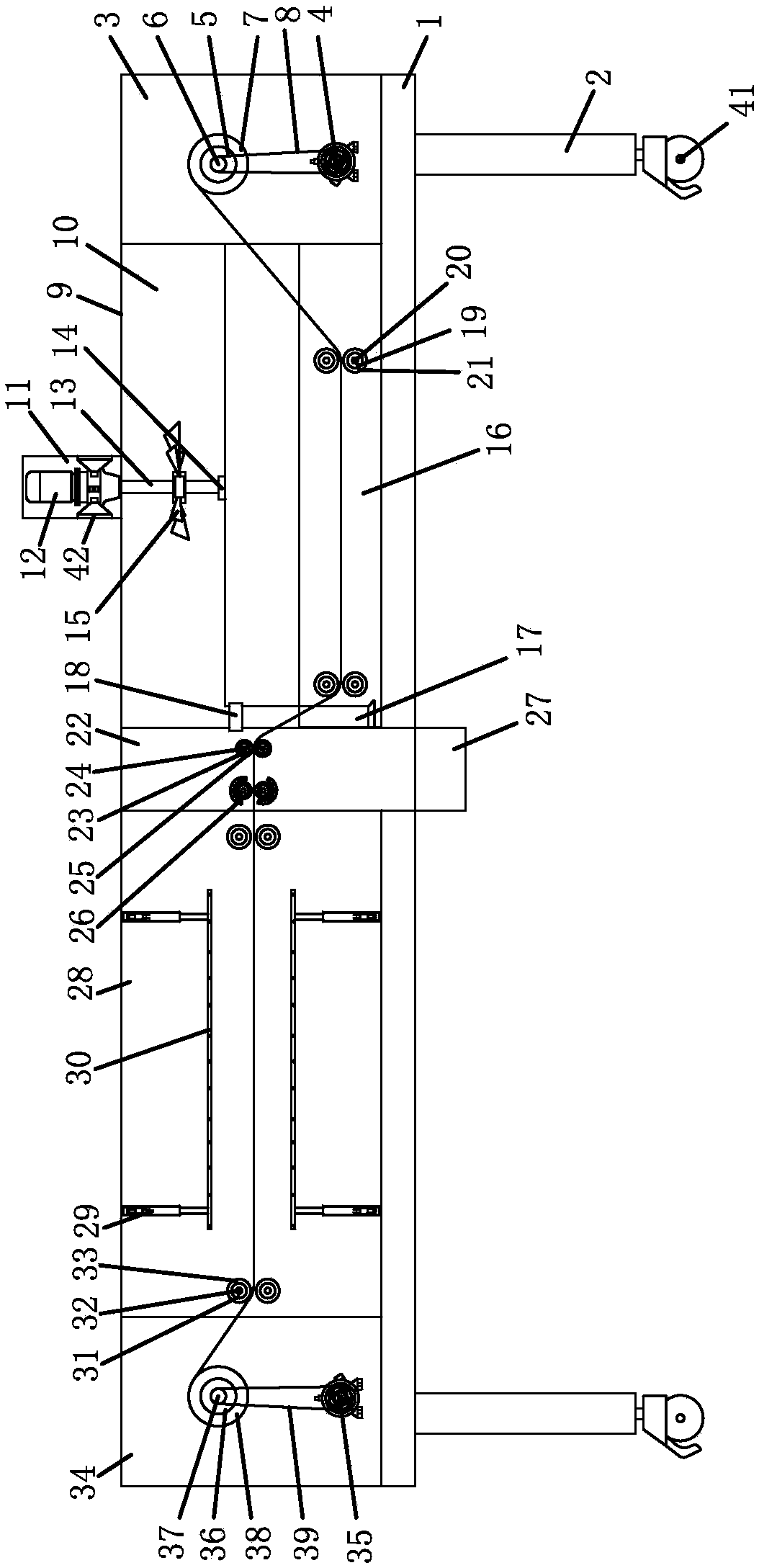

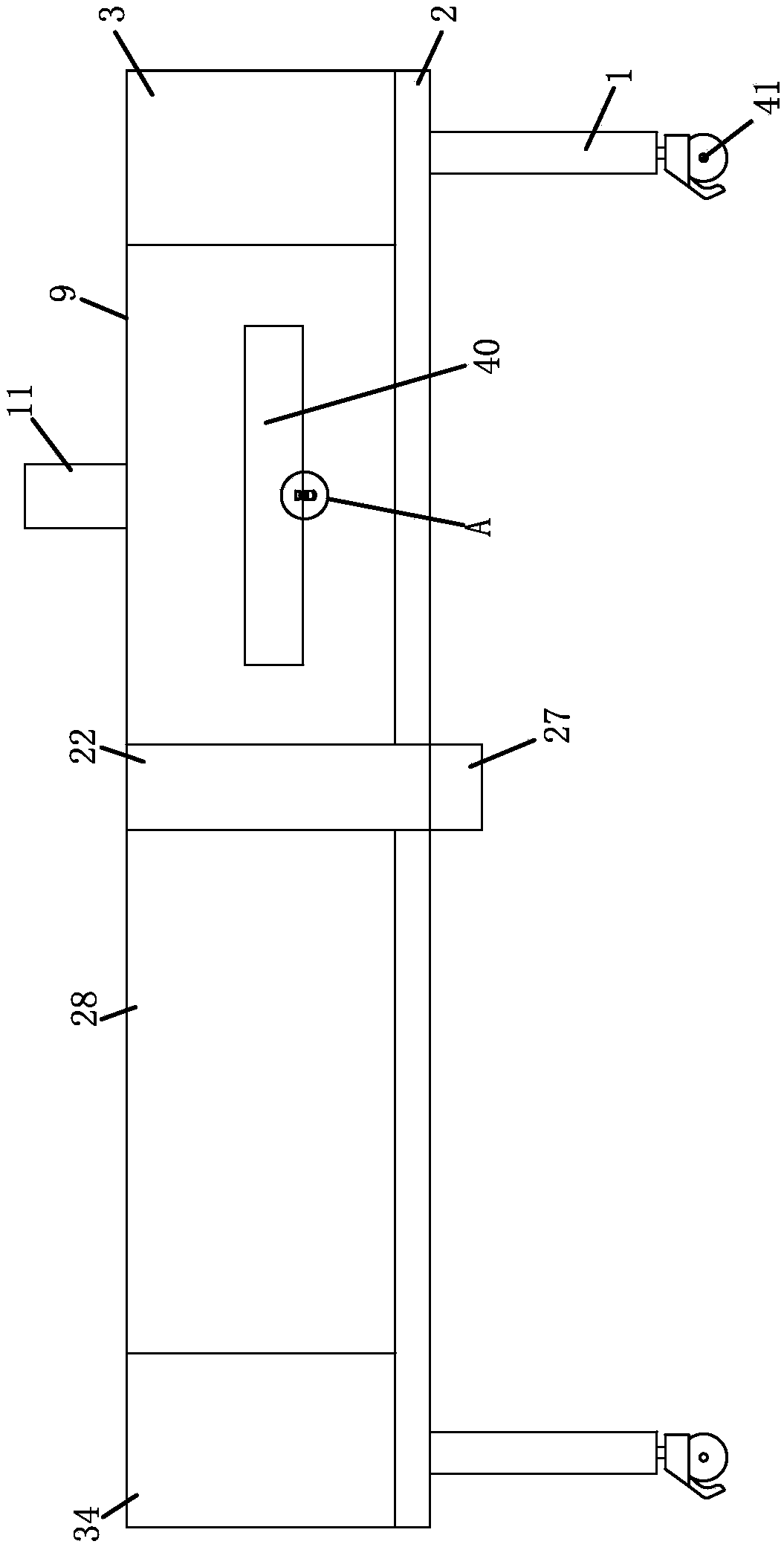

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

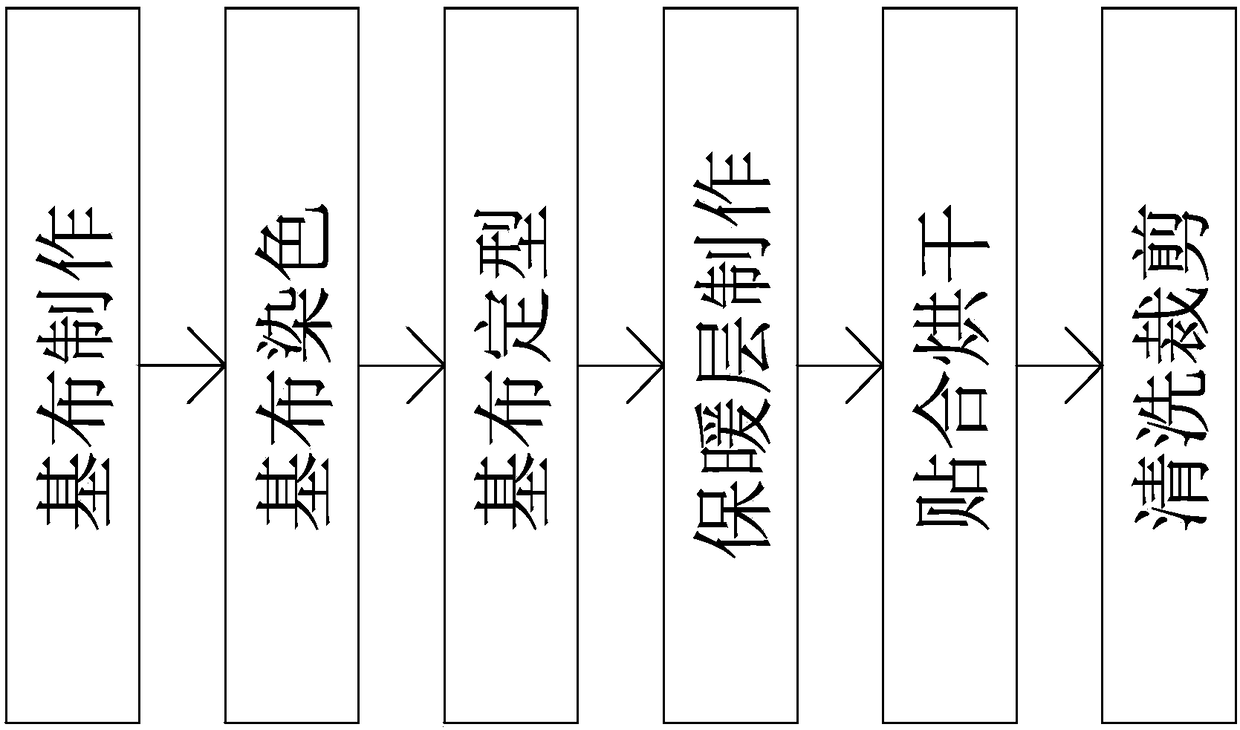

[0027] Such as Figure 1-4 Shown, a kind of warm waterproof fabric manufacturing process, this manufacturing process comprises the following steps:

[0028] S1. Base fabric production: The base fabric is woven from cotton warp and polyester weft materials;

[0029] S2. Base fabric dyeing: Dyeing the base fabric in step S1 by using a textile dyeing device, soaking the base fabric in the textile dyeing device for 30-40 minutes; drying the soaked base fabric at 80-85°C ; Rinse the dried base cloth in clean water for 10-20 minutes; dry the rinsed base cloth at 45-50°C;

[0030] S3, the base cloth is shaped: a shaping machine is used to shape the base cloth in step S2;

[0031] S4. Production of thermal insulation layer: wea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com