Strength-toughening treatment method of W6Mo5Cr4V2 high-speed steel broaching tool

A processing method and technology for high-speed steel, applied in heat treatment furnaces, heat treatment equipment, coatings, etc., can solve the problems of energy saving, unsatisfactory production costs, and many process steps, and achieve good blade regrindability, improved service life, and improved The effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

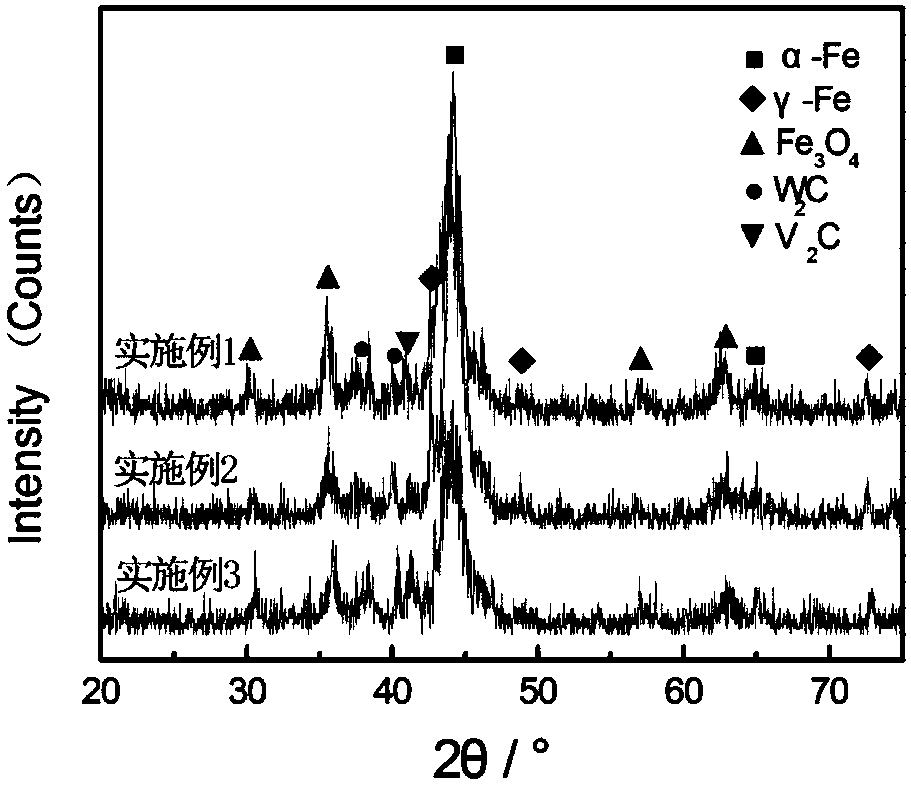

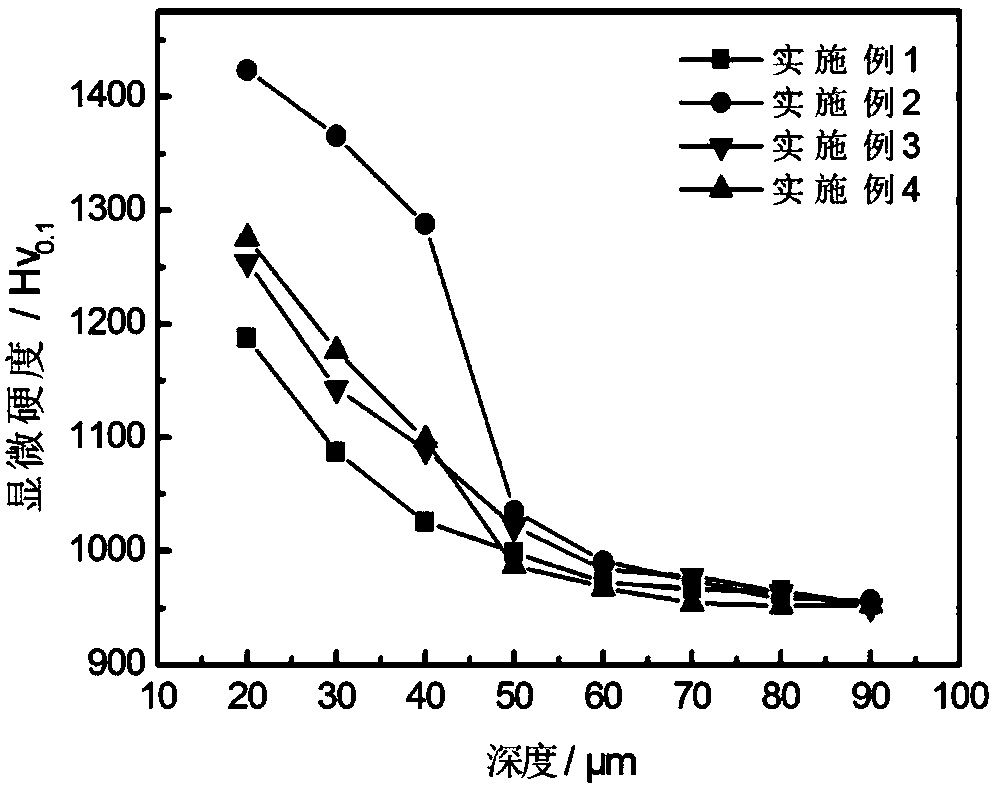

Embodiment 1

[0045] The strengthening and toughening treatment method of W6Mo5Cr4V2 high-speed steel spline broach with a size of Φ30×900mm is as follows:

[0046]Step 1, graded quenching: Preheat the high-speed steel broach in an air furnace at 500°C for 2 hours at low temperature; preheat it in a salt bath furnace at 870°C for 10 minutes at medium temperature; heat it in a high temperature salt bath furnace to 1220°C for 5 minutes; then Quenching in stages in a salt bath at a temperature of 550°C for 5 minutes.

[0047] Step 2, high-temperature tempering: temper the quenched high-speed steel broach in a 560°C salt bath furnace for 1 hour, then air-cool to room temperature, and perform 2 tempering according to this process.

[0048] Step 3, salt bath nitriding: the high-speed steel broach obtained in step 2 is subjected to salt-bath carbonitriding treatment, the method is as follows: (1) cleaning: the high-speed steel broach is cleaned with water to remove the salt on the surface; (2 ) P...

Embodiment 2

[0053] The strengthening and toughening treatment method of W6Mo5Cr4V2 high-speed steel spline broach with a size of Φ30×900mm is as follows:

[0054] Step 1: Grading quenching: Preheat the high-speed steel broach in an air furnace at 500°C for 2 hours at low temperature; preheat it in a salt bath furnace at 870°C for 10 minutes at medium temperature; heat it in a high temperature salt bath furnace to 1220°C for 5 minutes; then Quenching in stages in a salt bath at a temperature of 550°C for 5 minutes.

[0055] Step 2: Tempering at high temperature: Temper the quenched high-speed steel broach in a salt bath furnace at 560°C for 1 hour, then air-cool to room temperature, and perform tempering twice according to this process.

[0056] Step 3: salt bath nitriding: the high-speed steel broach obtained in step 2 is subjected to salt-bath carbonitriding treatment, the method is as follows: (1) cleaning: the high-speed steel broach is cleaned with water to remove the salt on the surf...

Embodiment 3

[0061] The strengthening and toughening treatment method of W6Mo5Cr4V2 high-speed steel spline broach with a size of Φ30×900mm is as follows:

[0062] Step 1: Grading quenching: Preheat the high-speed steel broach in an air furnace at 500°C for 2 hours at low temperature; preheat it in a salt bath furnace at 870°C for 10 minutes at medium temperature; heat it in a high temperature salt bath furnace to 1220°C for 5 minutes; then Quenching in stages in a salt bath at a temperature of 550°C for 5 minutes.

[0063] Step 2: Tempering at high temperature: Temper the quenched high-speed steel broach in a salt bath furnace at 560°C for 1 hour, then air-cool to room temperature, and perform tempering twice according to this process.

[0064] Step 3: salt bath nitriding: the high-speed steel broach obtained in step 2 is subjected to salt-bath carbonitriding treatment, the method is as follows: (1) cleaning: the high-speed steel broach is cleaned with water to remove the salt on the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com