Method of separating vanadium and chromium quickly by means of centrifugal extraction and preparing ammonium metavanadate

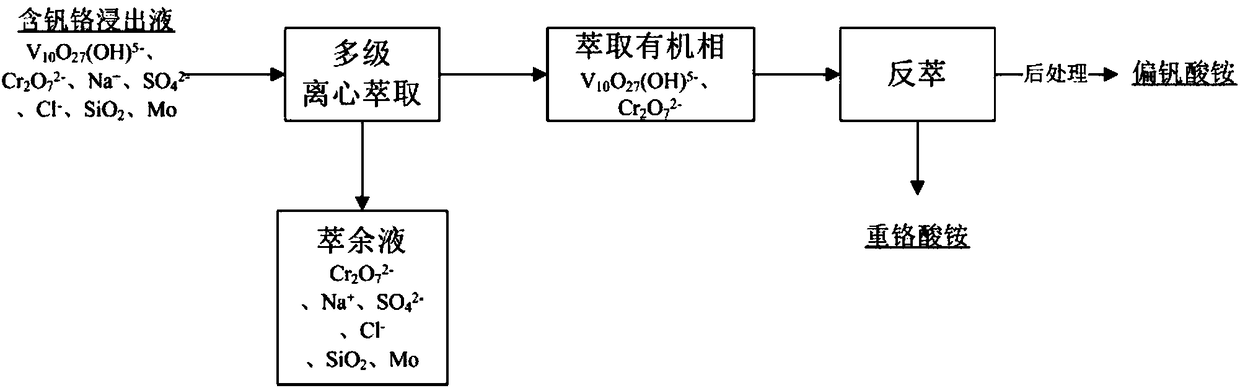

An ammonium metavanadate and extraction technology, which is applied in the field of ammonium metavanadate preparation, can solve the problems of easy degradation of the extractant and many extraction stages, and achieves the effects of providing a recycling rate, reducing an oxidation reaction process and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The present embodiment provides a kind of fast centrifugation extracting and separating vanadium chromium and the method for preparing ammonium metavanadate, described method comprises the following steps:

[0064] (1) adopt primary amine sulfate extractant and vanadium-containing chromium leachate to carry out centrifugal extraction and separation:

[0065] The concentration of vanadium element is 23.7g / L, and initial pH is 5 vanadium-containing chromium leachate and primary ammonium sulphate extraction agent are mixed, and described primary amine sulphate extraction agent is (C 15 h 31 NH) 2 SO 4 , (C 17 h 35 NH) 2 SO 4 and (C 19 h 39 NH) 2 SO 4 The mixture of the primary amine sulfate extractant and the vanadium-chromium-containing leaching solution is 1:1, and the molar ratio of the primary amine sulfate extractant to the vanadium-chromium-containing leaching solution is 1:5. , carry out 4-stage countercurrent centrifugal extraction and separation, contro...

Embodiment 2

[0070] The present embodiment provides a kind of fast centrifugation extracting and separating vanadium chromium and the method for preparing ammonium metavanadate, described method comprises the following steps:

[0071] (1) adopt primary amine sulfate extractant and vanadium-containing chromium leachate to carry out centrifugal extraction and separation:

[0072] The vanadium element concentration is 15g / L, the vanadium-chromium-containing leaching solution that initial pH is 7 is mixed with primary ammonium sulphate extraction agent, and described primary amine sulphate extraction agent is (C 8 h 17 NH) 2 SO 4 , under the condition that the ratio of the two phases of the primary amine sulfate extractant and the vanadium-chromium-containing leach solution is 1:2, and the molar ratio of the primary amine sulfate extractant and the vanadium-containing chromium leach solution is 1:1, Carry out 4-stage countercurrent centrifugal extraction and separation, control the temperat...

Embodiment 3

[0077] The present embodiment provides a kind of fast centrifugation extracting and separating vanadium chromium and the method for preparing ammonium metavanadate, described method comprises the following steps:

[0078] (1) adopt primary amine sulfate extractant and vanadium-containing chromium leachate to carry out centrifugal extraction and separation:

[0079] The vanadium element concentration is 20g / L, and the vanadium-chromium-containing leaching solution that initial pH is 8 is mixed with the primary amine sulfate extraction agent, and the primary amine sulfate extraction agent is (C 12 h 25 NH) 2 SO 4 , under the condition that the ratio of primary amine sulfate extractant and vanadium-chromium-containing leaching solution two-phase ratio is 1:3, and the mol ratio of primary amine sulfate extractant and vanadium-containing chromium leaching solution is 1:9, Carry out 4-stage countercurrent centrifugal extraction and separation, control the temperature of countercu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com