Functional anti-fatigue health care knitted fabric and preparation method thereof

A knitted fabric, anti-fatigue technology, applied in dyeing, dry-cleaning fiber products, textiles and papermaking, etc., to achieve the effects of promoting skin microcirculation, outstanding anti-fatigue performance, and smooth cloth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

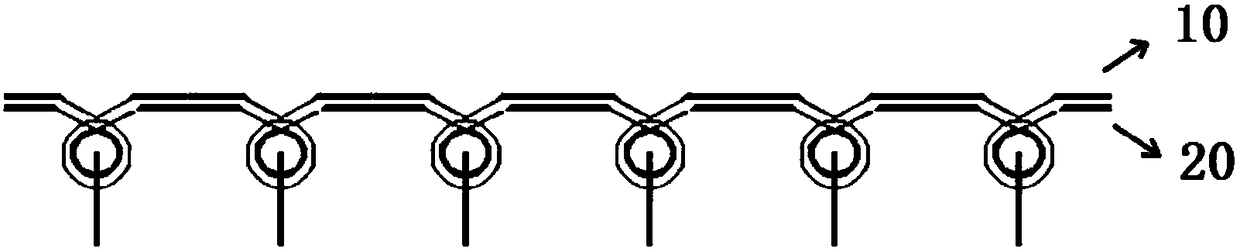

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 functional anti-fatigue health care knitted fabric

[0030] (1) 60 parts by weight of nano-scale inorganic germanium, 25 parts of acrylic resin, 20 parts of tea saponin, and 12 parts of diethanolamine are added to the container and fully mixed to prepare a finishing agent; the particle diameter of the nano-scale inorganic germanium 40-50nm. The groove-shaped moisture-absorbing fibers with special-shaped cross-section are fine-denier polyester filaments, and the profile of the special-shaped cross-section is cross-shaped, and there are three independent cavities inside, forming a special-shaped structure with high hollowness. The linear density of the fine denier polyester filament is 70D; the linear density of the milk protein fiber filament is 80D;

[0031] (2) Put the groove-shaped moisture-absorbing fiber with special-shaped cross-section or its filament or its blended yarn into the finishing agent prepared in step (1) and run for 1.5...

Embodiment 2

[0037]The preparation of embodiment 2 functional anti-fatigue health care knitted fabrics

[0038] (1) 50 parts by weight of nano-scale inorganic germanium, 30 parts of acrylic resin, 25 parts of tea saponin, and 14 parts of diethanolamine are added to the container and fully mixed to prepare a finishing agent; the particle diameter of the nano-scale inorganic germanium 40-50nm. The groove-shaped moisture-absorbing fibers with special-shaped cross-section are fine-denier polyester filaments, and the profile of the special-shaped cross-section is cross-shaped, and there are three independent cavities inside, forming a special-shaped structure with high hollowness. The linear density of the fine denier polyester filament is 50D; the linear density of the milk protein fiber filament is 75D;

[0039] (2) Put the groove-shaped moisture-absorbing fiber with special-shaped cross-section or its filament or its blended yarn into the finishing agent prepared in step (1) and dip it at 5...

Embodiment 3

[0045] Embodiment 3 Preparation of functional anti-fatigue health care knitted fabric

[0046] (1) 60 parts by weight of nano-scale inorganic germanium, 30 parts of acrylic resin, 15 parts of tea saponin, and 10 parts of diethanolamine are added to the container and fully mixed to prepare a finishing agent; the particle diameter of the nano-scale inorganic germanium 40-50nm. The groove-shaped moisture-absorbing fibers with special-shaped cross-section are fine-denier polyester filaments, and the profile of the special-shaped cross-section is cross-shaped, and there are three independent cavities inside, forming a special-shaped structure with high hollowness. The linear density of the fine denier polyester filament is 100D; the linear density of the milk protein fiber filament is 100D;

[0047] (2) Put the groove-shaped moisture-absorbing fiber with special-shaped cross-section or its filament or its blended yarn into the finishing agent prepared in step (1) and run for 0.8h ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com