Functional optical fiber evanescent field sensor based on solid phase extraction and assembly method of functional optical fiber evanescent field sensor

An assembly method and evanescent field technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of limited sensing distance, high production cost, poor stability, etc., to improve selectivity and sensitivity, eliminate matrix interference, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

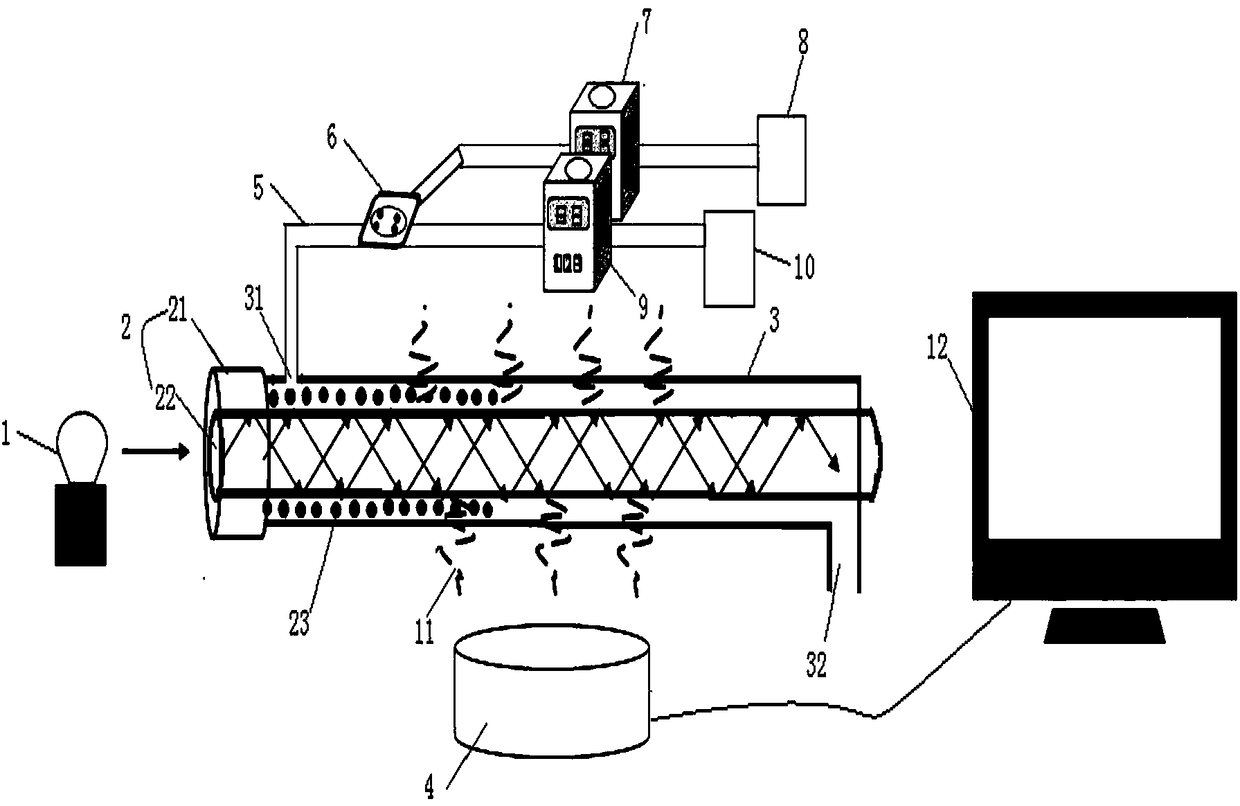

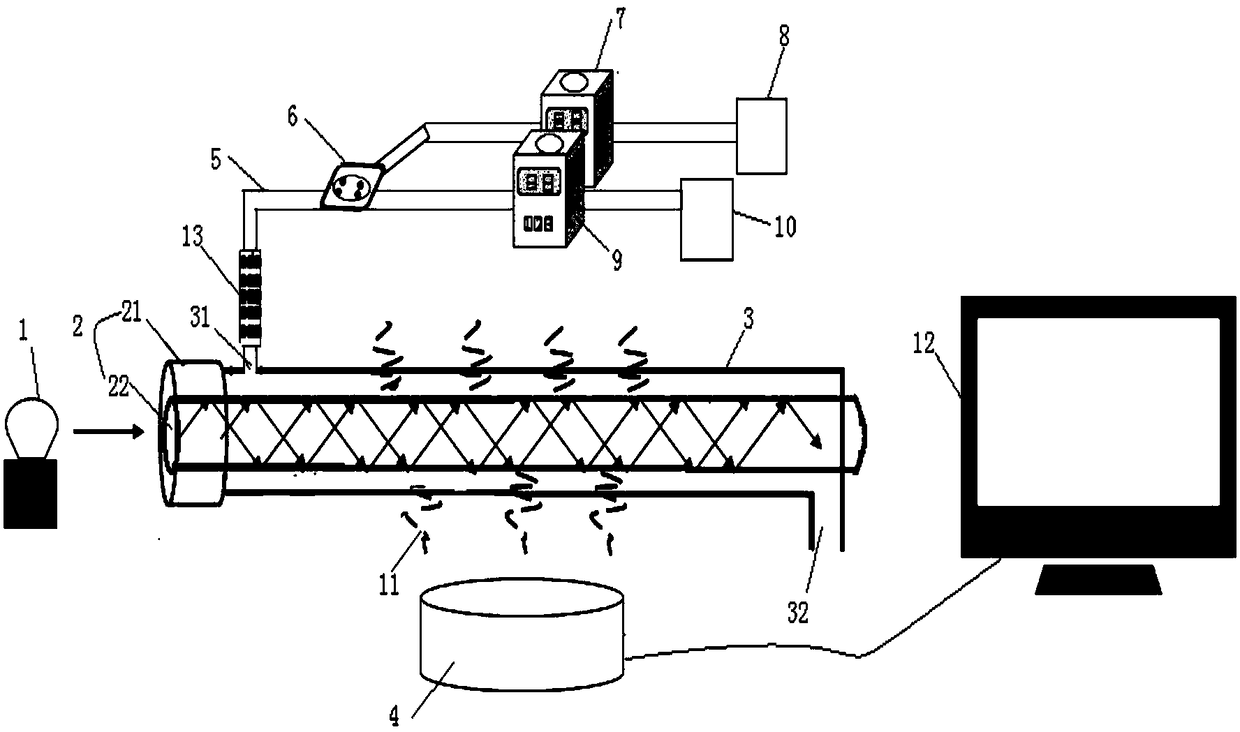

[0047] Such as figure 1 As shown, the present invention provides a solid phase extraction functional optical fiber evanescent field sensor, including a light source 1, an optical fiber 2, a capillary 3, a photomultiplier tube detector 4 and a liquid delivery unit. The light source is an LED lamp with a specific wavelength, and the power consumption is 15mA×3.05V. The inner diameter of the optical fiber is 0.6mm, and the inner diameter of the capillary is 0.8mm.

[0048] The left end of the optical fiber retains the outer cladding 21 on the surface, and the middle and right end parts completely remove the outer cladding to expose the optical fiber core 22. The optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com