A method for constructing a plant-microbe fuel cell

A fuel cell and microorganism technology, applied in the field of plant-microbial fuel cells, can solve problems such as affecting the power generation performance of P-MFC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

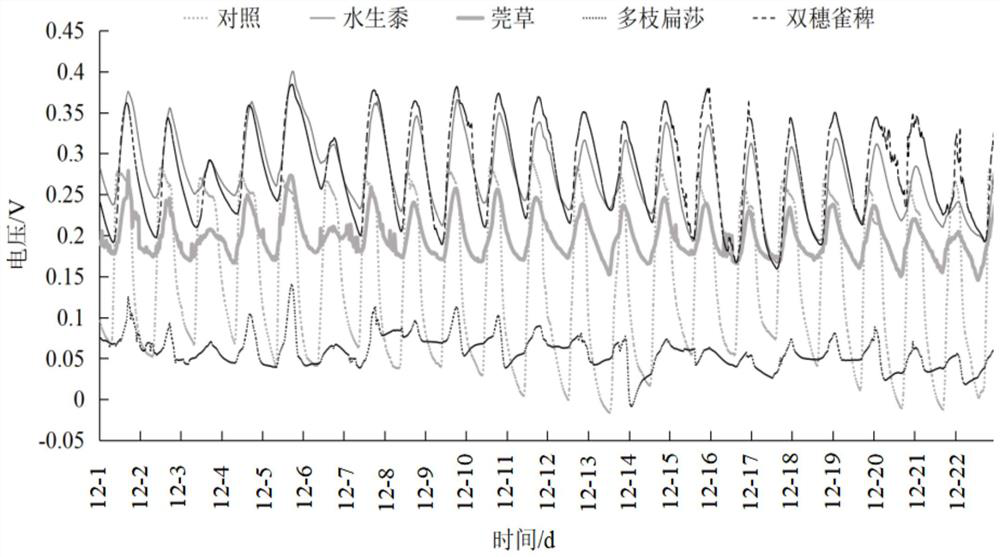

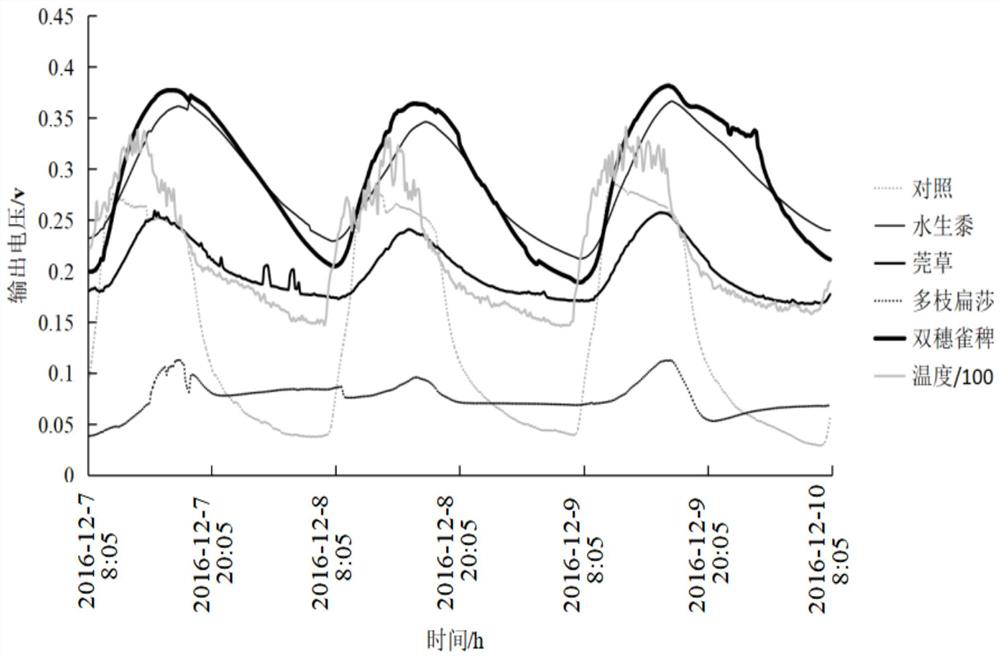

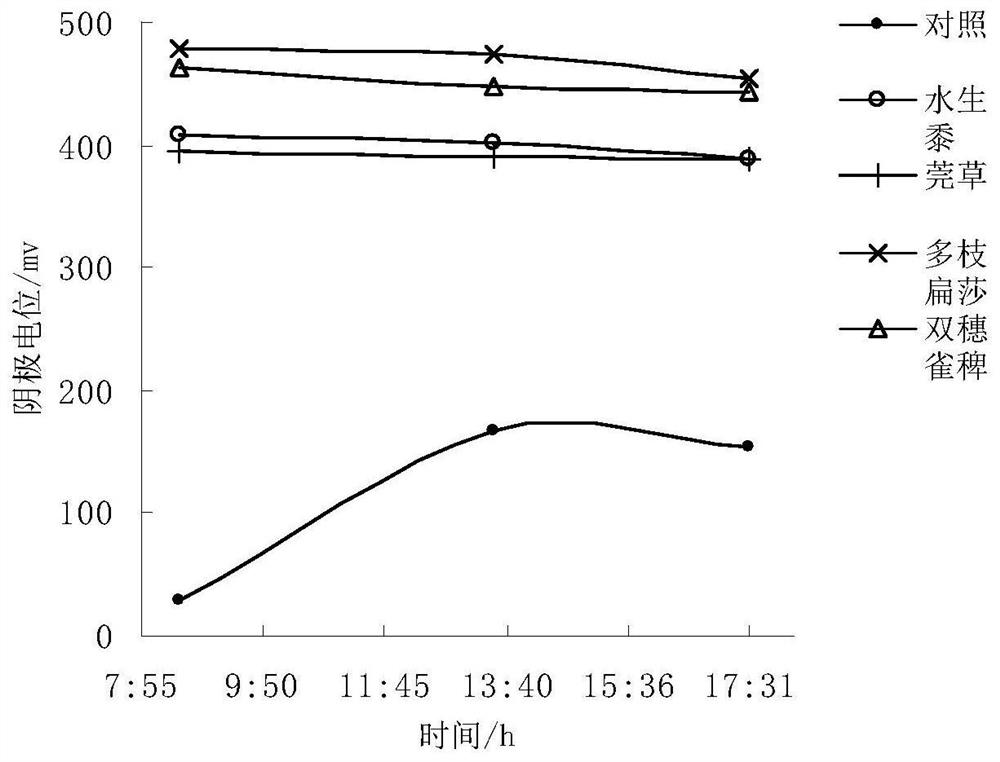

Examples

Embodiment 1

[0029] An embodiment of a method for constructing a plant microbial fuel cell according to the present invention, the method described in this embodiment comprises the following steps:

[0030] (1) Preparing the matrix: take the soil below 50 cm depth from the riverside wetland, air-dry it, and grind it through a 100-mesh sieve to obtain the matrix.

[0031] (2) Plant materials and propagation and cultivation: Four plants, namely Panicum paludosum, Cyperus malaccensis var. brevifolius, Pycreus polystachyus and Paspalumpaspaloides, were selected as experimental materials. About 15-20cm healthy stem section or seedling with buds, put it in a plastic bucket with sandy soil and organic matter content of 0.9% for rooting and culture, take it out after 2 weeks, wash the root system and transfer it to the substrate in step (1) grown in plastic pots.

[0032] (3) Construct a single-chamber air-cathode P-MFC without an ion-exchange membrane: use a Φ21cm high 20cm black plastic drum as...

Embodiment 2

[0047] The method of this embodiment is the same as that of Embodiment 1 except that the cathode and anode electrodes in step (3) are made of platinum-containing catalyst composite material, and the wire is copper wire.

[0048] The result of this embodiment is similar to that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0050] The method of this embodiment is the same as that of Embodiment 1 except that the cathode and anode electrodes in step (3) are made of carbon cloth, and the wires are silver wires.

[0051] The result of this embodiment is similar to that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com