Photothermoelectric conversion module and manufacturing method thereof

A technology for converting components and photothermal power, which is applied in photovoltaic power generation, electrical components, photovoltaic power stations, etc., can solve the problems of large temperature difference between the two ends of component electrodes and limit the wide application of generators, so as to improve the degree of integration and avoid the decrease of temperature gradient , Increase the effect of light-receiving area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

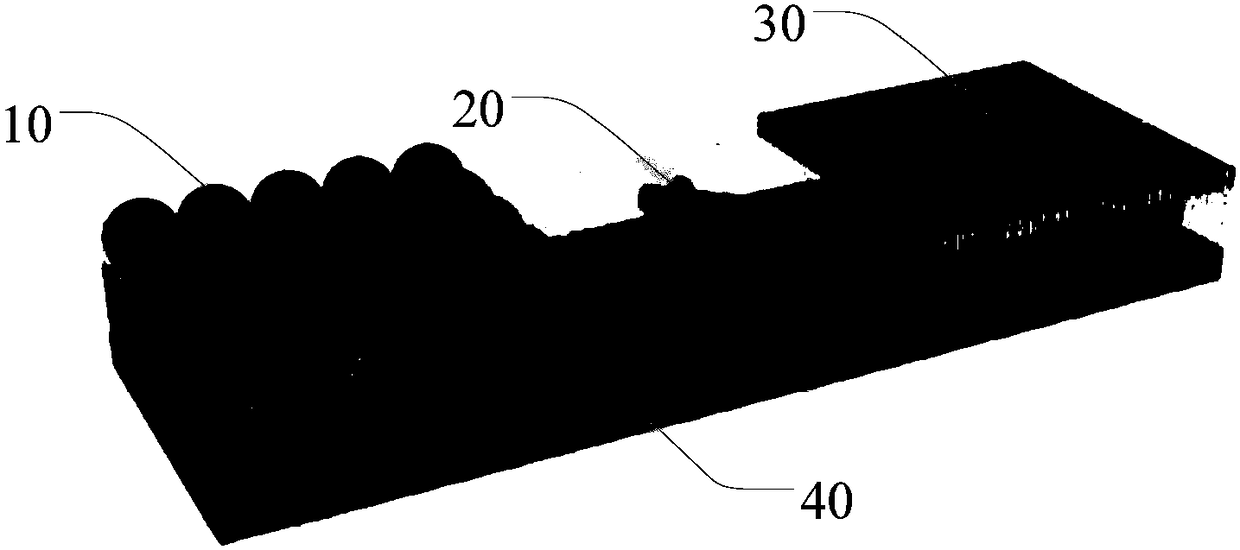

[0024] figure 1 It is a schematic structural diagram of a photothermoelectric conversion module according to an embodiment of the present invention. refer to figure 1 , The photothermoelectric conversion assembly includes a photothermal unit 10, an electrode 30, an insulating support substrate 40, and a thermoelectric unit 20 formed between the photothermal unit 10, the electrode 30 and the insulating support substrate 40. The photothermoelectric conversion component is a conversion component for converting light energy into thermal energy, and then converting thermal energy into electrical energy, and includes a photothermal unit for realizing photothermal conversion and a thermoelectric unit for realizing thermoelectric conversion.

[0025] Depend on figure 1 As shown, the projections of the photothermal unit 10 and the electrode 30 on the insulating support substrate 40 do not overlap. Because, if the projections of the photothermal unit 10 and the electrode 30 on the in...

Embodiment 2

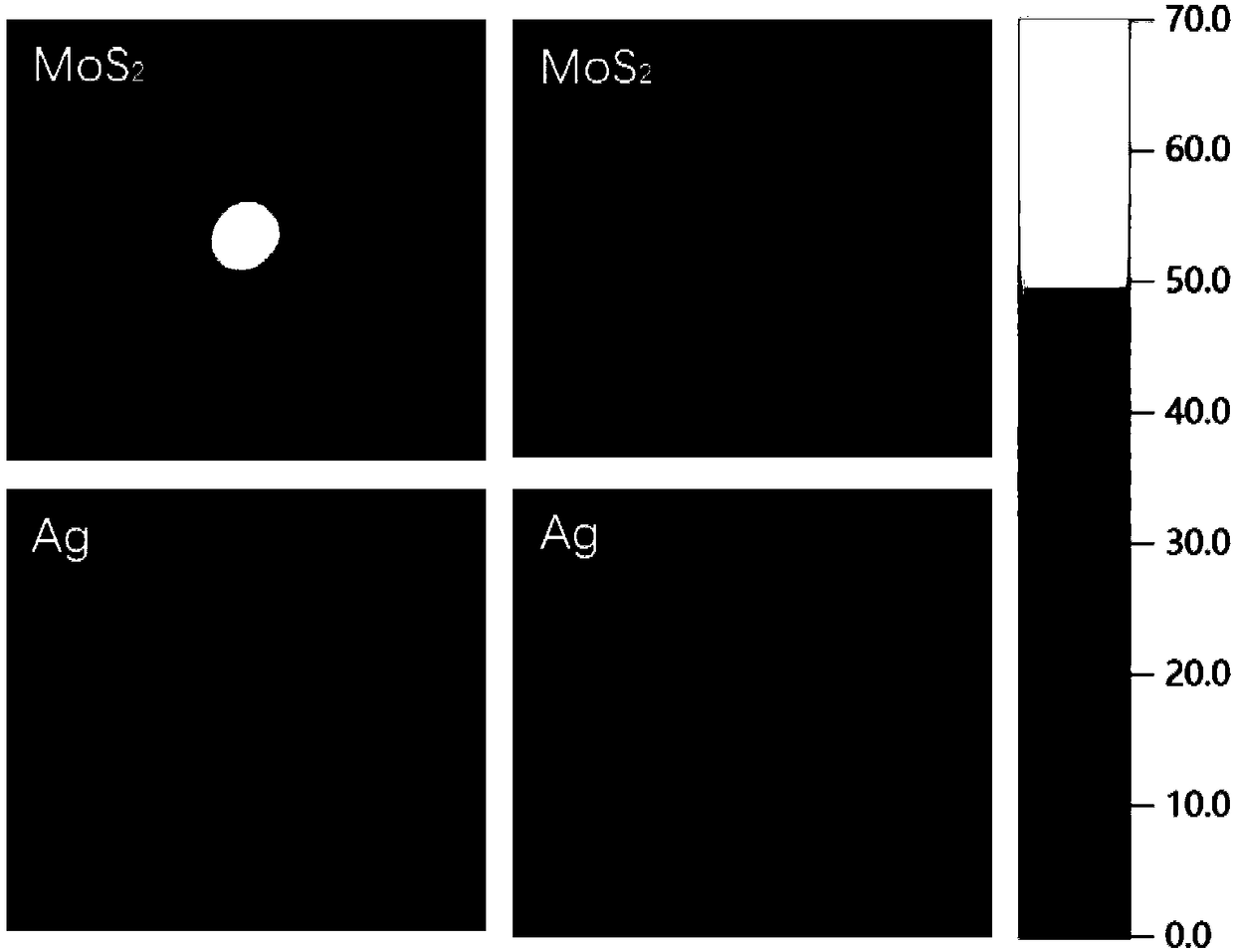

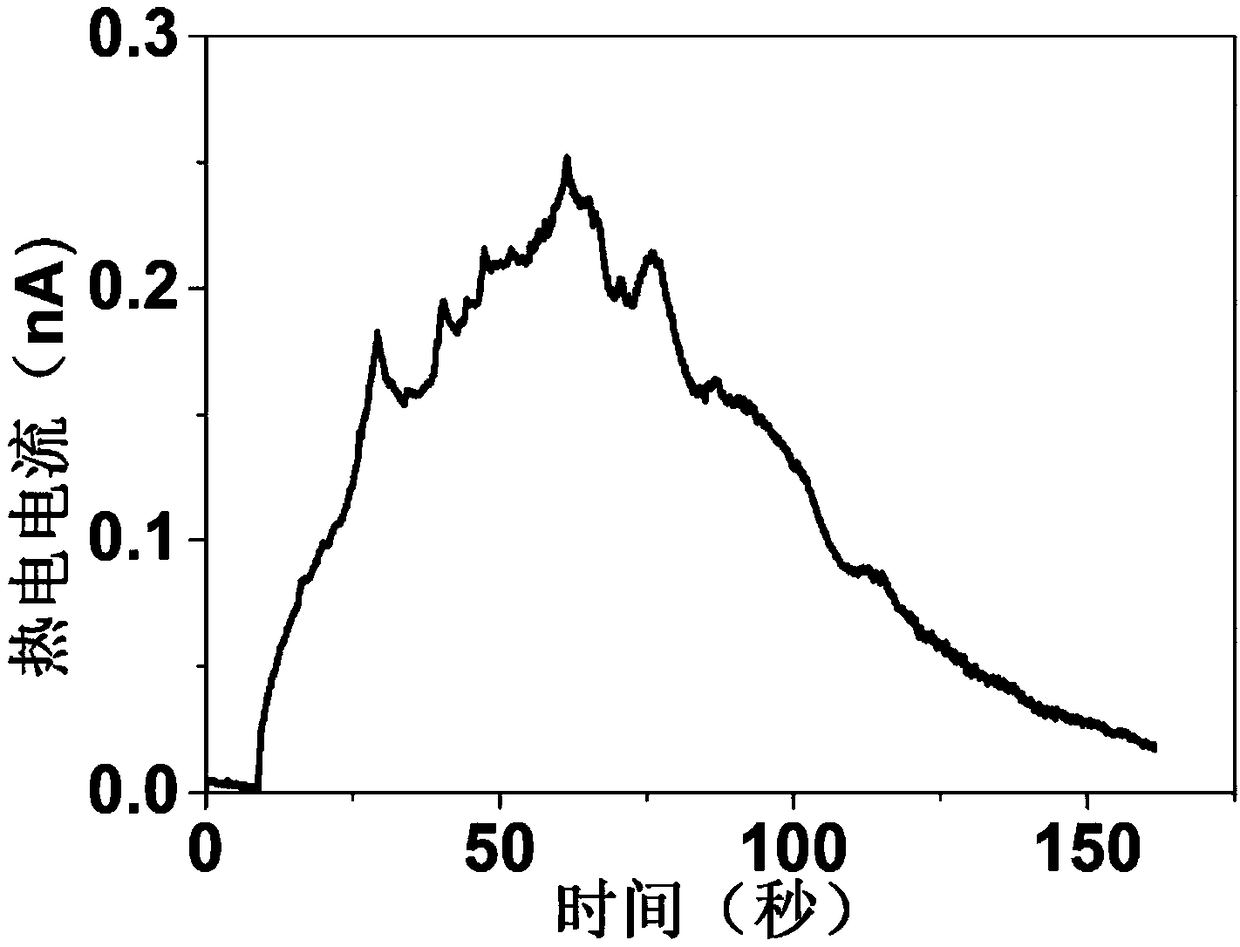

[0031] preparation figure 1 Structural photothermoelectric conversion components using MoS 2 Two-dimensional nanomaterials as photothermal materials. MoS 2 Two-dimensional nanomaterials are efficient photothermal materials with high photothermal conversion efficiency. MoS has been used 2 The characteristics of absorbing infrared light, and placing it in the body as a photothermal material for cancer treatment research, that is, MoS 2 Light-to-heat conversion can be achieved, but currently the MoS 2 There is no relevant report on the study of photothermal-electric conversion media. figure 2 It is a thermal imaging diagram of the photothermal unit 10 and the electrode 30 of the photothermoelectric conversion assembly. The photothermal unit 10 is MoS formed by mixing molybdenum disulfide and graphene slurry 2 / graphene film, the electrode is an Ag electrode. refer to figure 2 , when the infrared light with an optical power of 100mW and a wavelength of 808nm irradiates...

Embodiment 3

[0037] According to the method of manufacturing the photothermoelectric conversion module according to the embodiment of the present invention, the preparation is as follows: figure 1 The thermoelectric unit 20 is shown, and a photothermal unit 10 and an electrode 30 formed of photothermal material and conductive paste are formed at both ends of the thermoelectric unit 20. The electrode 30 may be formed of a metallic material such as silver (Ag), conductive oxide, or conductive polymer. The silver electrode is an infrared reflective material. The infrared reflective material can also be silver, aluminum, copper, etc. This material can reflect infrared rays instead of absorbing them, which can prevent the electrodes and thermoelectric units from heating up and reduce the temperature difference between them and the photothermal unit, thereby improving the photo-thermal-electricity. conversion efficiency.

[0038] For the convenience of manufacture, the thermoelectric unit 20 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com