Steel sheet for cans and production method for steel sheet for cans

A manufacturing method and technology for steel plates, which are applied in chemical instruments and methods, coating of superimposed layers, transportation and packaging, etc., can solve the problems of metal powder mixed with contents, danger, and increased maintenance burden such as canning equipment cleaning, etc. Excellent surface appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0116] Hereinafter, an Example is given and this invention is demonstrated concretely. However, the present invention is not limited to these Examples.

[0117] 〔Manufacture of steel plate for cans〕

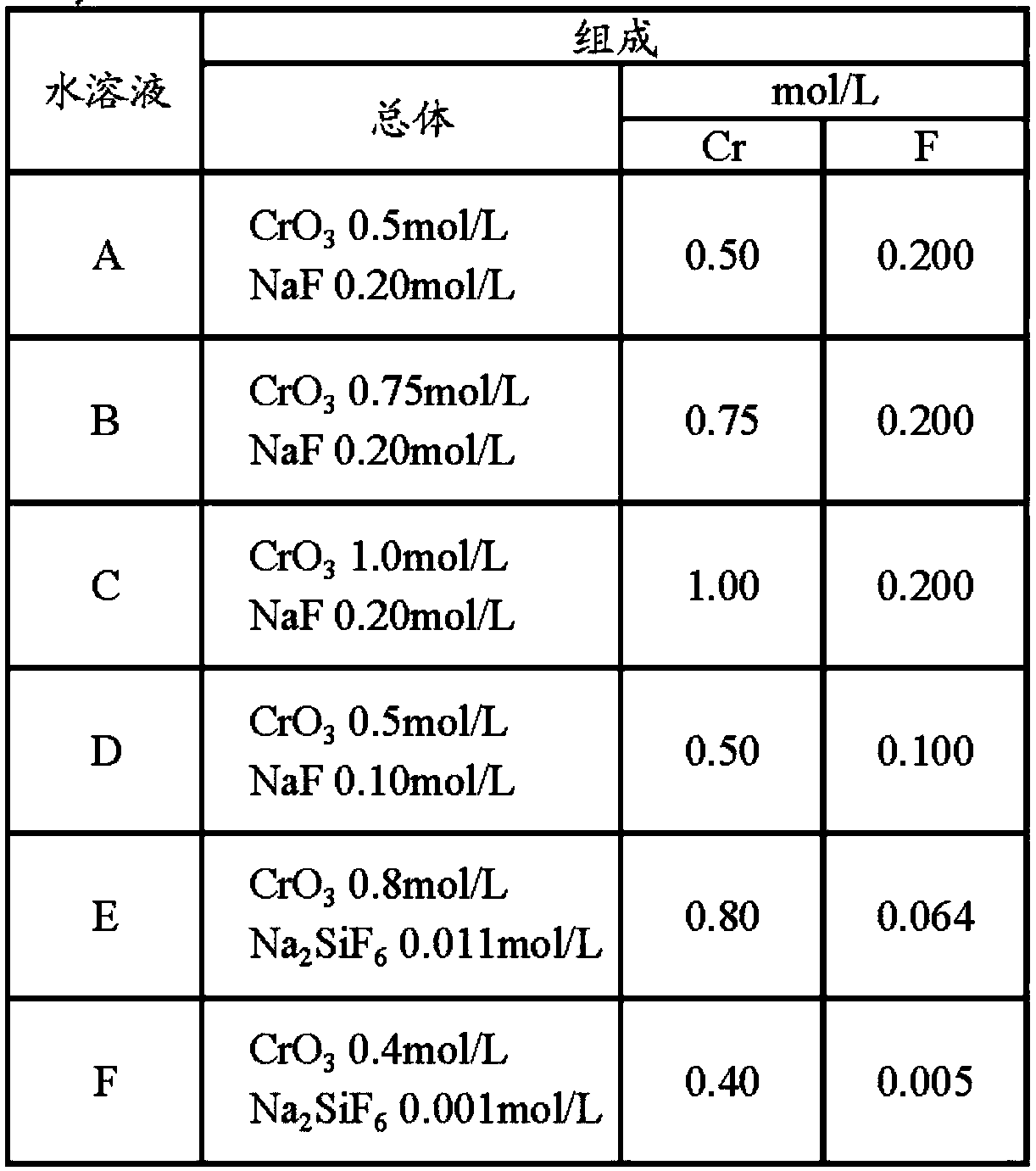

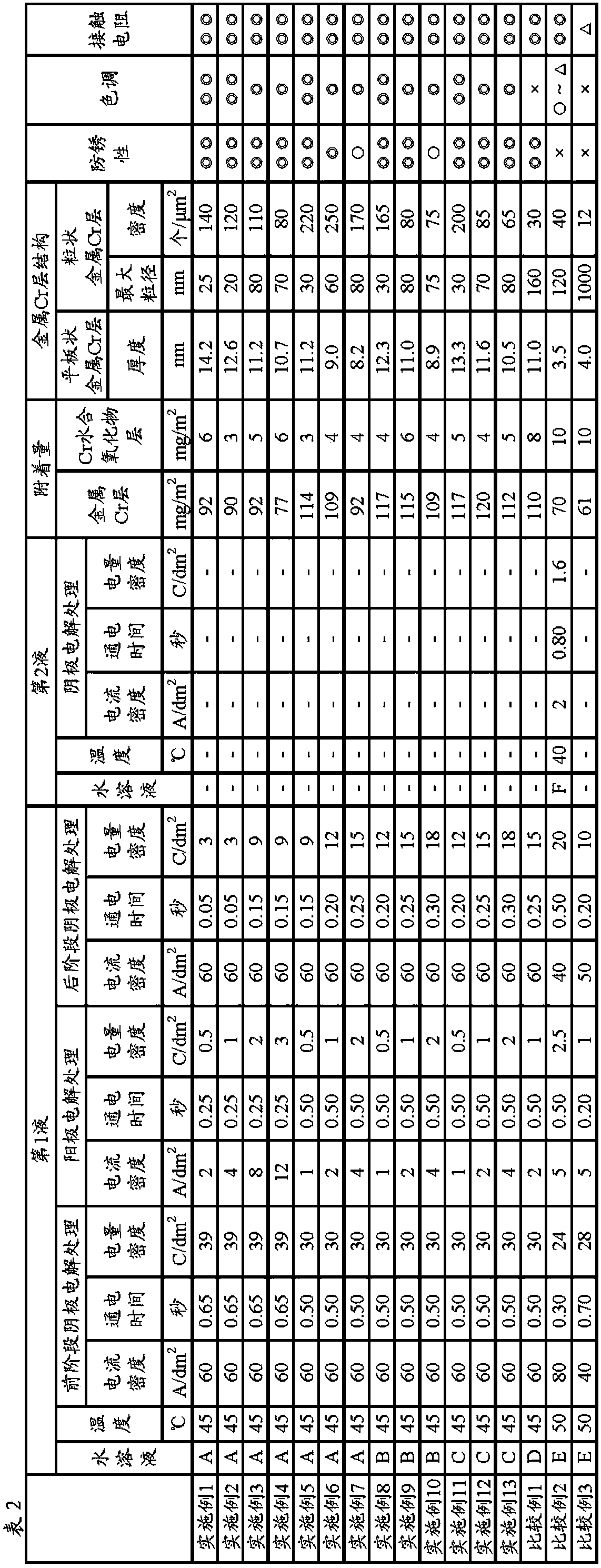

[0118] A steel plate with a tempering degree of T4CA manufactured with a plate thickness of 0.22 mm is subjected to normal degreasing and pickling, and then the aqueous solution shown in the following Table 1 is circulated by a pump at an equivalent of 100 mpm in a flow tank, and a lead electrode is used. Electrolytic treatment was performed under the conditions shown in Table 2 below to produce TFS steel sheets for cans. The produced cans are washed with water on a steel plate and dried at room temperature with a hair dryer.

[0119] More specifically, only in Comparative Example 2, after performing cathodic electrolytic treatment in the first stage, anodic electrolytic treatment, and cathodic electrolytic treatment in the latter stage using the first liquid (aqueous solution ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap