Preparation technology and products of wolfberry ferment

A technology of wolfberry enzyme and black fruit wolfberry, which is applied in the direction of food ingredients, the function of food ingredients, food ingredients as taste improvers, etc., can solve the problems of health value discount, low anthocyanin content, high degree of heat, etc., and achieve process optimization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A black fruit wolfberry ferment, by weight, the raw material of black fruit wolfberry ferment comprises:

[0038] 20 parts of black fruit wolfberry, 3 parts of maca, 5 parts of Juma, 2 parts of sea buckthorn powder, 5 parts of inulin, 13 parts of honey, 20 parts of brown sugar, and the rest is water.

[0039] The preparation technology of black fruit wolfberry ferment comprises the steps:

[0040] (1) Raw material beating

[0041] Add sterile water to clean fresh black wolfberry fruit and directly beat it; the weight ratio of fresh fruit to sterile water is 1:2;

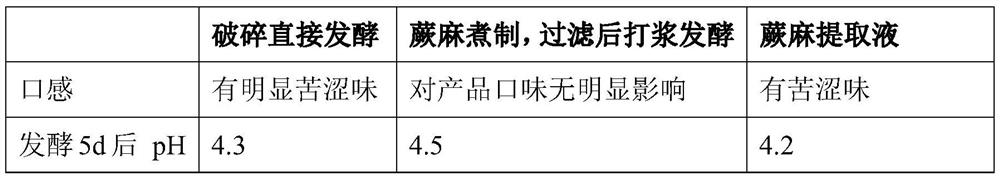

[0042] Soak the clean maca or junima in water first, the weight ratio of maca or junima to water is 1:2, and heat to 90°C to sterilize for 45 minutes, filter to remove part of the filtrate, and beat the rest. During the beating process, you can add aseptic water;

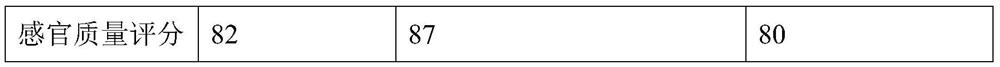

[0043] (2) The first stage of fermentation

[0044] Mix seabuckthorn powder, wolfberry pulp, maca pulp, fern pulp and a quarter of the weight o...

Embodiment 2

[0050] A black fruit wolfberry ferment, by weight, the raw material of black fruit wolfberry ferment comprises:

[0051] 25 parts of black fruit wolfberry, 2 parts of maca, 5 parts of Juma, 3 parts of sea buckthorn powder, 7 parts of inulin, 17 parts of honey, 23 parts of brown sugar, and the rest is water.

[0052] The preparation technology of black fruit wolfberry ferment comprises the steps:

[0053] (1) Raw material beating

[0054] Clean black wolfberry is soaked in water, heated to 90°C to sterilize for 30 minutes, and then beaten; the weight ratio of dried fruit to water is 1:4;

[0055] Soak the clean maca or junima in water first, the weight ratio of maca or junima to water is 1:2, and heat to 90°C to sterilize for 45 minutes, filter to remove part of the filtrate, and beat the rest. During the beating process, you can add aseptic water;

[0056] (2) The first stage of fermentation

[0057]Mix seabuckthorn powder, wolfberry pulp, maca pulp, fern pulp and a quarte...

Embodiment 3

[0064] A black fruit wolfberry ferment, by weight, the raw material of black fruit wolfberry ferment comprises:

[0065] 15 parts of black wolfberry, 4 parts of maca, 3 parts of fern, 5 parts of sea buckthorn powder, 10 parts of inulin, 20 parts of honey, 25 parts of sugar, water.

[0066] The preparation technology of black fruit wolfberry ferment comprises the steps:

[0067] (1) Raw material beating

[0068] The clean dried fruit of black wolfberry is soaked in water, heated to 90°C to sterilize for 30 minutes, and then beaten; the weight ratio of dried fruit to water is 1:4;

[0069] Soak the clean maca or junima in water first, the weight ratio of maca or junima to water is 1:2, and heat to 90°C to sterilize for 45 minutes, filter to remove part of the filtrate, and beat the rest. During the beating process, you can add aseptic water;

[0070] (2) The first stage of fermentation

[0071] Mix seabuckthorn powder, wolfberry pulp, maca pulp, fern pulp and 1 / 4 weight of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com