High-wear-resistance plant gene lubricating oil additive as well as preparation method and application thereof

A lubricating oil additive and high wear-resistant technology, applied in the field of lubricating oil, can solve the problems of shortened service life of mechanical equipment and vehicles, environmental pollution, loss of lubricating function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

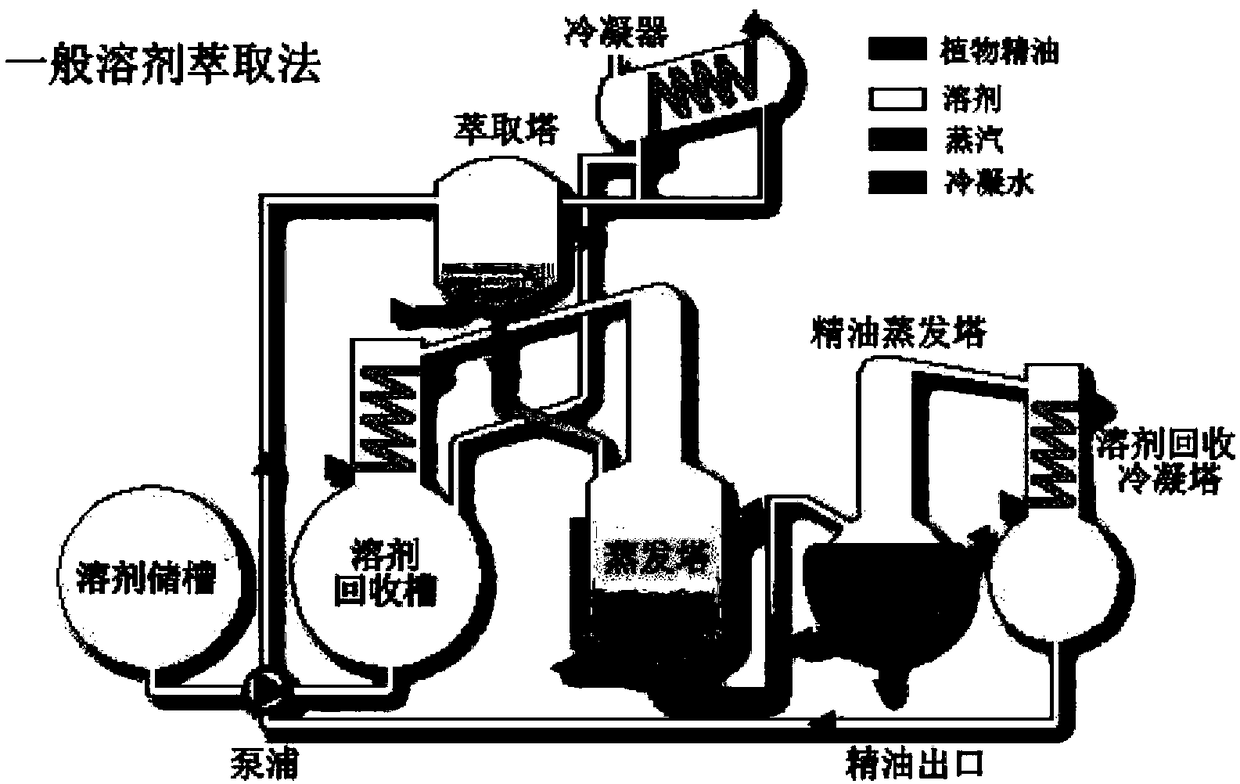

Image

Examples

Embodiment 1

[0029] A high wear-resistant vegetable gene lubricating oil additive, calculated by volume percentage, including 15% soybean oil, 15% rapeseed oil, 15% sesame oil, 5% peanut oil, 15% olive oil, 5% castor oil, salad 15% oil, 5% sunflower oil, 7% tung oil and 3% airgel; wherein, the airgel is a porous material of 50 nanometers.

[0030] The preparation method of high wear-resistant vegetable gene lubricating oil additive:

[0031] 1. Preparation:

[0032] 1. Prepare vegetable blend oil:

[0033] (1) Mixing of raw materials: Pour the soybean oil, rapeseed oil, sesame oil, peanut oil, olive oil, castor oil, salad oil, and sunflower oil into the disperser according to the proportion at 1000 rpm, stir for 8 minutes, 2000 Turn and stir for 8 minutes, 3000 turn and stir for 12 minutes, fully stir evenly, and make synthetic vegetable oil;

[0034] (2) Reaction: Add the amount of tung oil in the synthetic vegetable oil prepared in (1), then heat to 75° C., disperse and stir at 3000 r...

Embodiment 2

[0046] A high wear-resistant vegetable gene lubricating oil additive, calculated by volume percentage, including 20% soybean oil, 10% rapeseed oil, 10% sesame oil, 10% peanut oil, 10% olive oil, 10% castor oil, salad 10% oil, 10% sunflower oil, 5% tung oil and 5% airgel; wherein, the airgel is a porous material of 100 nanometers.

[0047] The preparation method of high wear-resistant vegetable gene lubricating oil additive:

[0048] 1. Preparation:

[0049] 1. Prepare vegetable blend oil:

[0050](1) Mixing of raw materials: Pour the soybean oil, rapeseed oil, sesame oil, peanut oil, olive oil, castor oil, salad oil, and sunflower oil into the disperser according to the proportion at 1000 rpm, stir for 10 minutes, 2000 Turn and stir for 10 minutes, 3000 turn and stir for 10 minutes, fully stir evenly, and make synthetic vegetable oil;

[0051] (2) Reaction: Add the amount of tung oil in the synthetic vegetable oil prepared in (1), then heat to 80°C, disperse and stir at 3...

Embodiment 3

[0063] A high wear-resistant vegetable gene lubricating oil additive, calculated by volume percentage, including 5% soybean oil, 5% rapeseed oil, 5% sesame oil, 20% peanut oil, 5% olive oil, 20% castor oil, salad 5% oil, 20% sunflower oil, 5% tung oil and 10% airgel; wherein, the airgel is a porous material with a diameter of 150 nanometers.

[0064] The preparation method of high wear-resistant vegetable gene lubricating oil additive:

[0065] 1. Preparation:

[0066] 1. Prepare vegetable blend oil:

[0067] (1) Mixing of raw materials: Pour the soybean oil, rapeseed oil, sesame oil, peanut oil, olive oil, castor oil, salad oil, and sunflower oil into the disperser according to the proportion at 1000 rpm, stir for 12 minutes, 2000 Turn and stir for 12 minutes, 3000 turns and stir for 20 minutes, fully stir evenly, and make synthetic vegetable oil;

[0068] (2) Reaction: Add the amount of tung oil in the synthetic vegetable oil prepared in (1), then heat to 85° C., disperse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com