A kind of lining plate of ball mill barrel

A ball mill and lining plate technology, applied in grain processing and other directions, can solve the problems of intolerance to impact, waste, and heavy specific gravity, and achieve the effects of reducing impact load, stable product quality, and increasing buffer capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

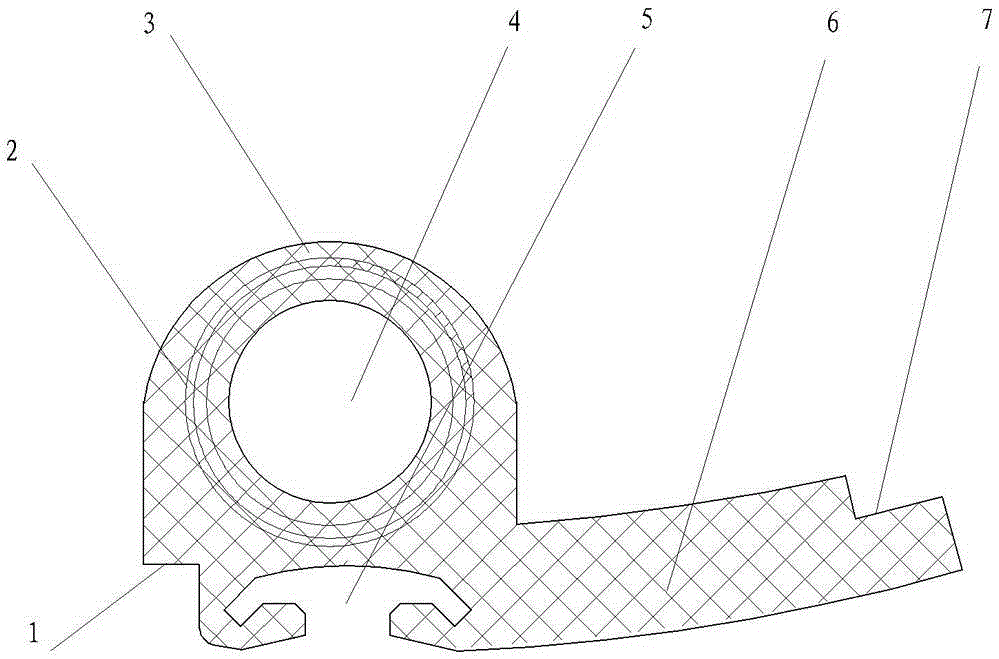

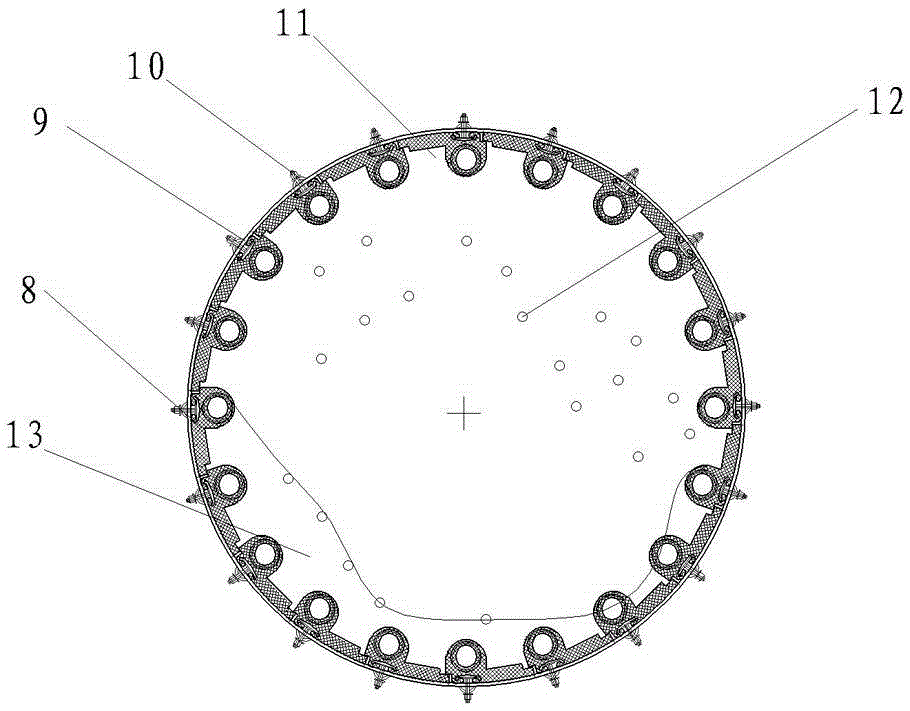

[0014] Such as figure 1 As shown, the rubber liner 8 is a whole, made of high-performance rubber and reinforced fabric fabric skeleton 2 composite vulcanization; the formula is: natural rubber NR: 70 parts, styrene-butadiene rubber 1502: 30 parts, 5 parts of zinc oxide, 3 parts of stearic acid, 1 part of paraffin, 1 part of coumarone, 1.5 parts of anti-aging agent D, 2.2 parts of anti-aging agent 4010, 50 parts of high wear-resistant carbon black, 5 parts of pine tar, accelerator 0.8 parts of CZ, 0.4 parts of accelerator DM, 1.2 parts of adhesive AS-88, 1.5 parts of sulfur, and the total mass parts are 173.6 parts. The rubber liner is produced by a conventional vulcanization process, the production equipment is a vulcanizing machine, the temperature is 143°C, and the time is 57 minutes.

[0015] The shape of the rubber liner 8 is a horizontal P shape, including a pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com