High-strength and high-wear-resistance composite brazing coating for repairing water turbine blade

A technology of brazing coating and repairing water, which is applied in the field of repairing coatings on the surface of water turbine blades, can solve problems such as low bonding strength, difficult thickness, and complicated procedures, and achieve the goals of increasing surface hardness, improving wear resistance, and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

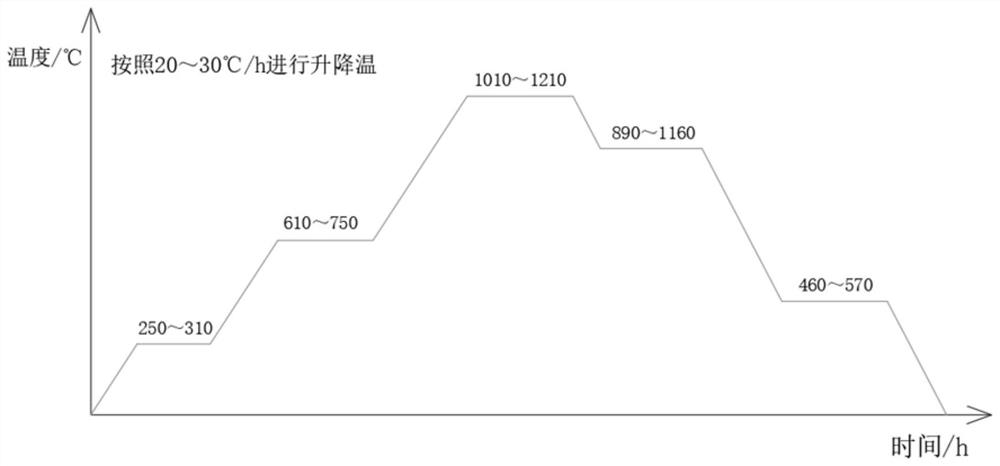

Method used

Image

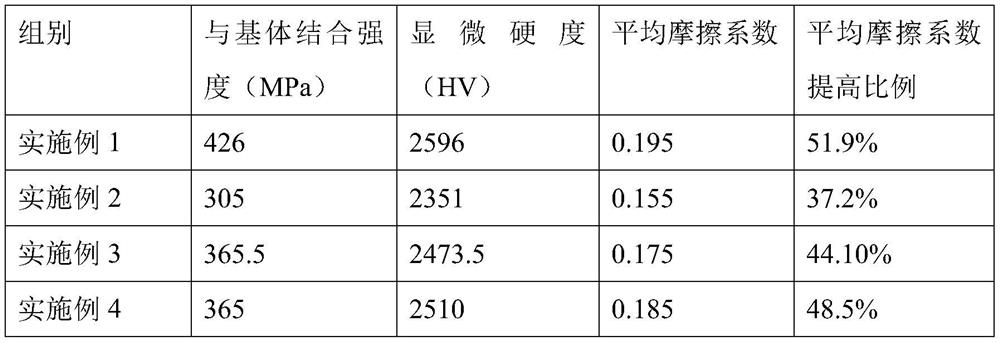

Examples

Embodiment 1

[0021] A high-strength and high-wear-resistant composite braze coating for repairing turbine blades, which is made by mixing low-melting-point brazing filler metal with a weight percentage of 9:1 and high-melting-point cemented carbide, and then coating and heating. The low-melting-point brazing filler metal It is a mixture of iron-based solder, copper-based solder, and nickel-based solder. The high-melting-point cemented carbide is a mixture of carbide and boride.

[0022] According to the weight percentage, the iron-based solder is a mixture of 55% iron powder, 25% titanium-iron powder, 5% molybdenum powder, 5% chromium powder, and 10% iron carbide. The melting temperature is 1030-1155 ° C; the copper-based solder is copper 79 %, nickel 12%, manganese 6%, rare earth praseodymium 3%, melting temperature 955 ~ 1045 ℃; nickel-based solder is nickel 81.5%, chromium 9.5%, boron 3%, yttrium 1%, iron 5% Mixed powdered solder, melting temperature 965 ~ 1130 ℃;

[0023] The carbide ...

Embodiment 2

[0035]A high-strength and high-wear-resistant composite braze coating for repairing turbine blades, which is made by mixing low-melting-point brazing filler metal and high-melting-point cemented carbide with a weight percentage of 1:1, and then coating and heating. The low-melting-point brazing filler metal It is a mixture of iron-based solder, copper-based solder, and nickel-based solder. The high-melting-point cemented carbide is a mixture of carbide and boride.

[0036] According to the percentage by weight, the iron-based solder is a mixture of 55% iron powder, 25% iron carbide, 5% molybdenum boride, 5% chromium powder, and 10% iron boride. The melting temperature is 1030-1145°C; the copper-based solder is copper 79%, nickel 12%, manganese 6%, rare earth yttrium 3% mixed solder, melting temperature 955 ~ 1040 ℃; nickel-based solder is nickel 81.5%, chromium 9.5%, boron 3%, yttrium 1%, iron 5% % mixed powdered solder, melting temperature 965 ~ 1130 ℃;

[0037] The carbide ...

Embodiment 3

[0042] A high-strength and high-wear-resistant composite braze coating for repairing turbine blades, which is made by mixing low-melting-point brazing filler metal with a weight percentage of 5:1 and high-melting-point cemented carbide, and then coating and heating. The low-melting-point brazing filler metal It is a mixture of iron-based solder, copper-based solder, and nickel-based solder. The high-melting-point cemented carbide is a mixture of carbide and boride.

[0043] According to the percentage by weight, the iron-based solder is 55% of iron powder, 25% of titanium-iron powder, 5% of molybdenum powder, 5% of chromium powder, and 10% of iron carbide, and the melting temperature is 1030-1155°C; the copper-based solder is 79% of copper, Mixed solder with 12% nickel, 6% manganese, and 3% rare earth praseodymium, melting temperature 955-1045°C; nickel-based solder is a mixture of 81.5% nickel, 9.5% chromium, 3% boron, 1% yttrium, and 5% iron Powdered solder, melting temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com