Method for coproduction of alcohol, fructose and multiple side products by using sweet sorghum stalks and corn

A technology of sorghum stalks and by-products, which is applied to the recovery of by-products, biochemical equipment and methods, and storage methods for animal feed raw materials to achieve the effects of increasing sugar content and wine content, reducing energy consumption, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

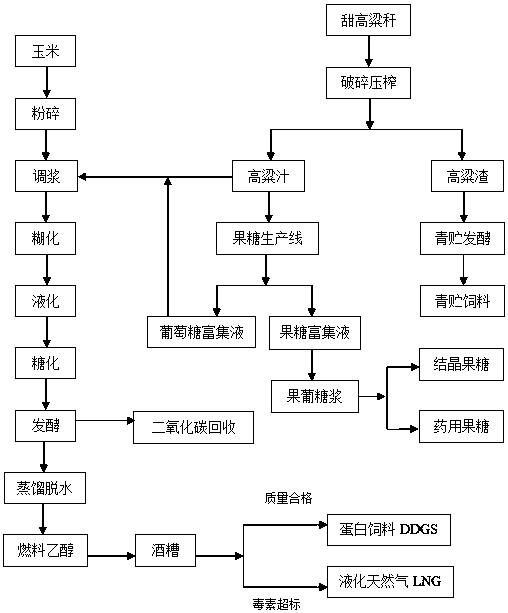

Image

Examples

Embodiment 1

[0040] In this embodiment, the method for co-producing ethanol, fructose and various by-products with sweet sorghum stalks and corn comprises the following process steps:

[0041] (1) Pretreatment of sweet sorghum stalks: fresh sweet sorghum stalks are crushed and squeezed with special sweet sorghum juicing equipment to obtain sorghum juice with a sugar content of 20.2% and sorghum juice with a water content of 57.5% and a sugar content of 5.1%. Sorghum slag.

[0042] (2) Corn pretreatment: Grinding dry corn granules containing 63.5% starch to obtain corn flour for later use.

[0043] (3) Preparation of fructose syrup and fructose: Sweet sorghum juice is used to prepare fructose syrup and fructose. The fructose includes crystalline fructose and medicinal fructose, and the by-product fructose syrup can be directly used as a product.

[0044] The preparation of high fructose syrup includes the following processes: 1. After the sweet sorghum juice is coarsely filtered by a centr...

Embodiment 2

[0051] In this embodiment, the method for co-producing ethanol, fructose and various by-products with sweet sorghum stalks and corn comprises the following process steps:

[0052] (1) Sweet sorghum stalk pretreatment: Fresh sweet sorghum stalks are crushed and squeezed with special sweet sorghum juicer to obtain sorghum juice with a sugar content of 23.7% and sorghum juice with a water content of 59.6% and a sugar content of 5.4%. Sorghum slag.

[0053] (2) Corn pretreatment: Grinding dry corn granules containing 65.4% starch to obtain corn flour for later use.

[0054] (3) Preparation of fructose syrup and fructose: sweet sorghum juice is used to prepare fructose syrup and fructose, the fructose includes crystalline fructose and medicinal fructose, and the by-product fructose syrup can be directly used as a product;

[0055] The preparation of high fructose syrup includes the following processes: 1. After the sweet sorghum juice is coarsely filtered by a centrifuge, a flat c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com