Preparation method of high-quality titanium-based boron-doped diamond coating

A boron-doped diamond, high-quality technology, used in metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of low ionization rate and inability to obtain ion bombardment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

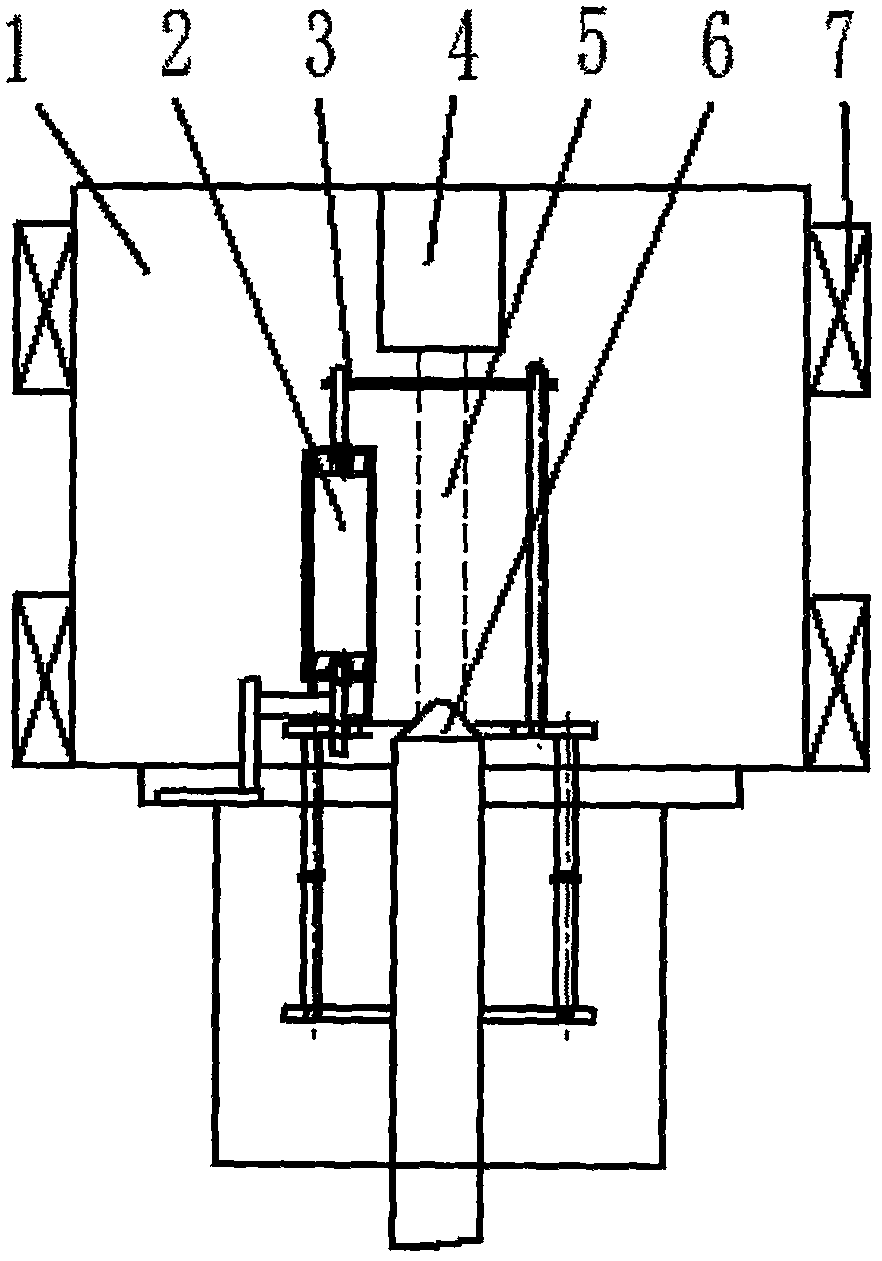

[0024] 50 mm outer diameter, 2 mm wall thickness, and 300 mm long titanium tube 2 are installed on the workpiece frame 3 of the DC arc plasma chemical vapor deposition device, and the center of the titanium tube 2 is 70 mm away from the center of the vacuum chamber. The specific operation process is as follows: 1) Use a vacuum pump to vacuum the back of the vacuum chamber 1 to below 1Pa. 2) The Ar flow rate is 1.5SLM, and the vacuum degree of the vacuum chamber is controlled to be 300Pa. The discharge between the cathode 4 and the anode 6 produces a plasma column 5, and the arc current is adjusted to 100A. 3) The flow rate is 200sccm of H 2 and CH with a flow rate of 40 sccm 4 , adjust the vacuum to 1200Pa. 4) Adjust the magnetic field current of the magnetic coil 7 to 50A. 5) Rotate the titanium tube 2 and apply a negative bias voltage of 100V to the titanium tube 2 for 20 minutes to prepare a TiC enriched layer. 6) SiH with a flow rate of 30 sccm 4 , adjust the negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com