Green ultrathin resin grinding wheel and preparation method thereof

A resin grinding wheel, ultra-thin technology, applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of poor safety factor, corrosion of metal, short service life, etc., to increase the surface finish and increase the combination Strength, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A green ultra-thin resin grinding wheel, including two upper and lower reinforced glass fiber meshes and a cutting body arranged between the two reinforced glass fiber meshes, the cutting body is composed of the following raw materials in parts by weight: primary single crystal 30 parts of corundum, 40 parts of first-grade iridium-plated white corundum, 25 parts of first-grade zirconium corundum, 15 parts of phenolic resin liquid, 15 parts of phenolic resin powder, 10 parts of potassium cryolite, 5 parts of iron sulfide, 10 parts of composite filler KEP2, titanium 1 part white powder, 0.3 part phthalo green,

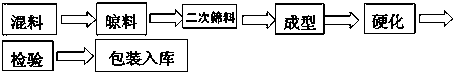

[0036] The preparation method of above-mentioned green ultra-thin resin emery wheel, as figure 1 As shown, it includes the following steps: (1) Mixing: Weigh the raw materials in proportion, pour the raw materials that make up the abrasive into the countercurrent mixing pot and stir evenly, add the phenolic resin solution and mix well, then add potassium cryolite ...

Embodiment 2

[0043] A green ultra-thin resin grinding wheel, including two upper and lower reinforced glass fiber meshes and a cutting body arranged between the two reinforced glass fiber meshes, the cutting body is composed of the following raw materials in parts by weight: primary single crystal 25 parts of corundum, 50 parts of first-grade iridium-plated white corundum, 30 parts of first-grade zirconium corundum, 10 parts of phenolic resin solution, 25 parts of phenolic resin powder, 5 parts of potassium cryolite, 10 parts of iron sulfide, 5 parts of composite filler KEP2, titanium 2 parts of white powder, 0.5 parts of phthalocyanine green,

[0044] The preparation method of above-mentioned green ultra-thin resin emery wheel, as figure 1 As shown, it includes the following steps: (1) Mixing: Weigh the raw materials in proportion, pour the raw materials that make up the abrasive into the countercurrent mixing pot and stir evenly, add the phenolic resin solution and mix well, then add pot...

Embodiment 3

[0051] A green ultra-thin resin grinding wheel, including two upper and lower reinforced glass fiber meshes and a cutting body arranged between the two reinforced glass fiber meshes, the cutting body is composed of the following raw materials in parts by weight: primary single crystal 30 parts of corundum, 50 parts of first-grade iridium-plated white corundum, 30 parts of first-grade zirconium corundum, 12 parts of phenolic resin liquid, 20 parts of phenolic resin powder, 8 parts of potassium cryolite, 8 parts of iron sulfide, 8 parts of composite filler KEP2, titanium 2 parts of white powder, 0.5 parts of phthalocyanine green,

[0052] The preparation method of above-mentioned green ultra-thin resin emery wheel, as figure 1 shown, including the following steps:

[0053] (1) Mixing: Weigh the raw materials in proportion, pour the raw materials that make up the abrasive into the countercurrent mixing pot and stir evenly, add the phenolic resin liquid and mix well, then add pot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com