High-strength and high-humidity-response poly-oxyamide and preparation method thereof

A polyhydroxyamide and humidity-responsive technology, applied in the field of high-strength humidity-responsive polyhydroxyamide and its preparation, can solve problems such as reduced mechanical properties, and achieve the effects of improved toughness, easy recovery, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

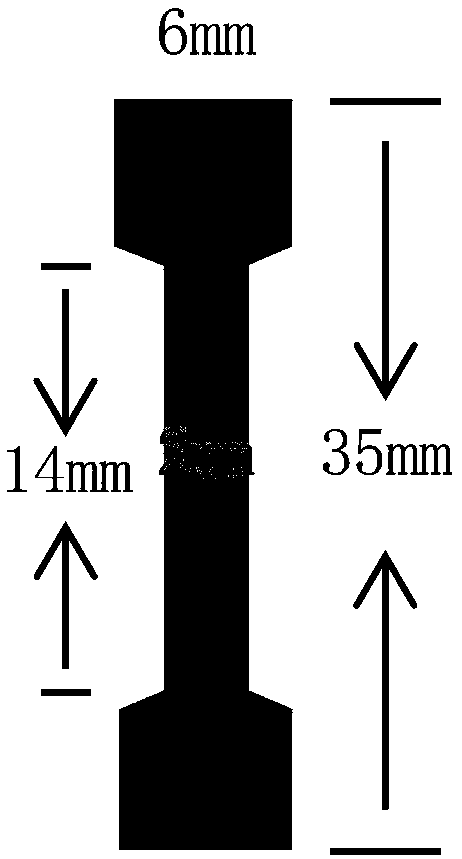

Image

Examples

Embodiment 1

[0038] The preparation of embodiment 1 polyhydroxyamide 1

[0039] Prepare polyhydroxyamide 1 as follows: Take 9.5 g of dimethyl sebacate and 3.7 g of 1,3 diamino-2-propanol and mix them uniformly at 70°C, add 250 μL of sodium methoxide solution (concentration: 5 mol / L), and seal at 70°C Heating for 12h. Connect the water pump to evacuate and heat to 100°C to react for 2 hours until there is no liquid in the reaction system (because the reaction raw material is liquid, the reaction by-product methanol is also liquid, but the target product is solid at this temperature), replace the water pump with an oil pump Vacuumize and heat to 150°C for 1 hour, and finally heat to 220°C for 1 hour with oil pump vacuum. After the reaction, the product was taken out and sealed for preservation.

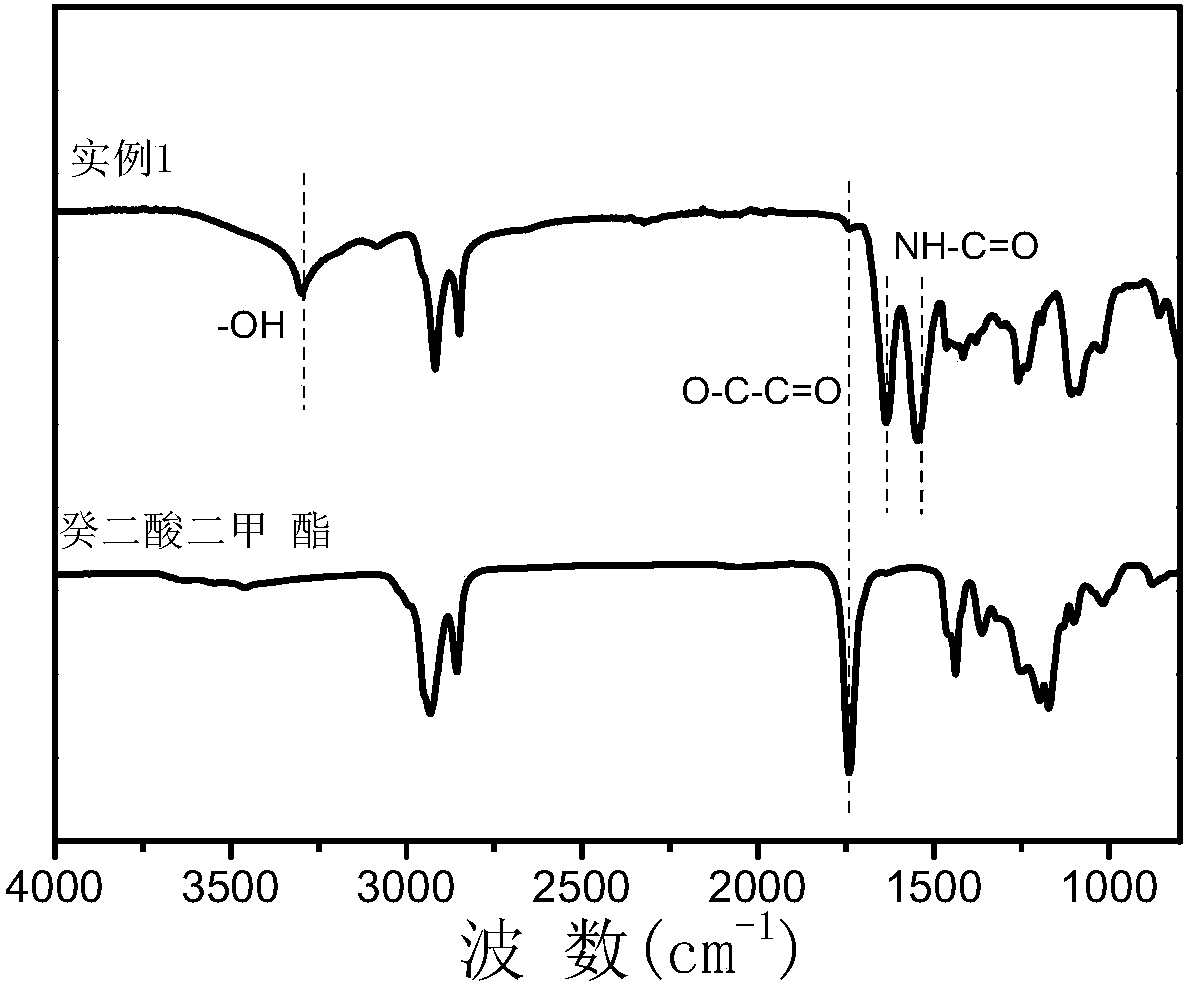

[0040] Such as figure 2 Shown: after the raw material dimethyl sebacate of the present invention is reacted according to Example 1, the peak of the ester group basically disappears, and the peak...

Embodiment 2

[0041] The preparation of embodiment 2 polyhydroxyamide 2

[0042] Prepare polyhydroxyamide 2 as follows: Take 3.5 g of dimethyl adipate and 1.9 g of 1,3 diamino-2-propanol and mix them uniformly at 70°C, add 130 μL of sodium methoxide solution (concentration: 5 mol / L), and seal at 70°C Heating for 10h. Connect the water pump to evacuate and heat to 100°C for 1.5h until there is no liquid in the reaction system, replace the water pump with an oil pump to evacuate and heat to 150°C for 0.9h, and finally heat to 220°C for 0.8h with the oil pump. After the reaction, the product was taken out and sealed for preservation.

[0043] Such as Figure 6 Shown: after the raw material dimethyl adipate of the present invention is reacted according to Example 2, the peak of the ester group basically disappears, and the peak of the amide group is newly generated, which means that the reaction is successful, and the ester is basically converted into an amide group. At the same time, there ...

Embodiment 3

[0044] The preparation of embodiment 3 polyhydroxyamide 3

[0045] Prepare polyhydroxyamide 3 as follows: Take 13.5 g of dimethyl malonate and 9.3 g of 1,3 diamino-2-propanol and mix them uniformly at 70°C, add 650 μL of sodium methoxide solution (concentration: 5 mol / L), and seal at 70°C Heating for 10h. Connect the water pump to evacuate and heat to 100°C for 1 hour until there is no liquid in the reaction system, replace the water pump with an oil pump to evacuate and heat to 150°C for 0.8 hour, and finally heat to 220°C for 1 hour by oil pump. After the reaction, the product was taken out and sealed for preservation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com