Transparent antibacterial super-hydrophobic coating and preparation method thereof

A super-hydrophobic coating, transparent technology, applied in coatings, anti-fouling/underwater coatings, biocide-containing paints, etc., can solve the problems of losing super-hydrophobicity, unstable surfaces, and easy collapse of micro-nano structures. Achieve the effect of increasing surface roughness, stabilizing hydrophobicity and improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

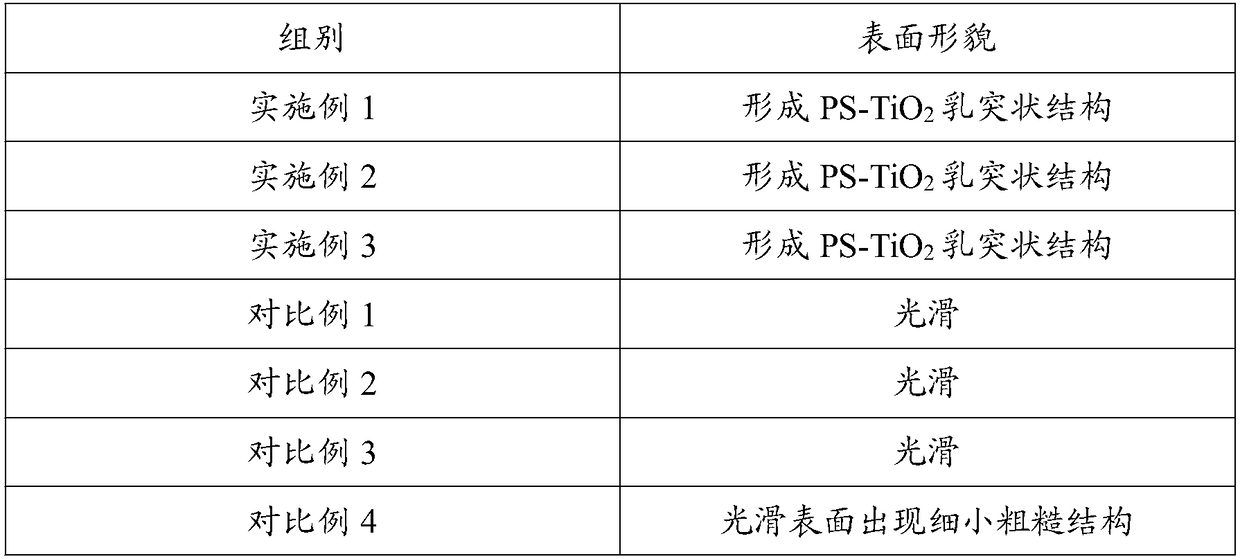

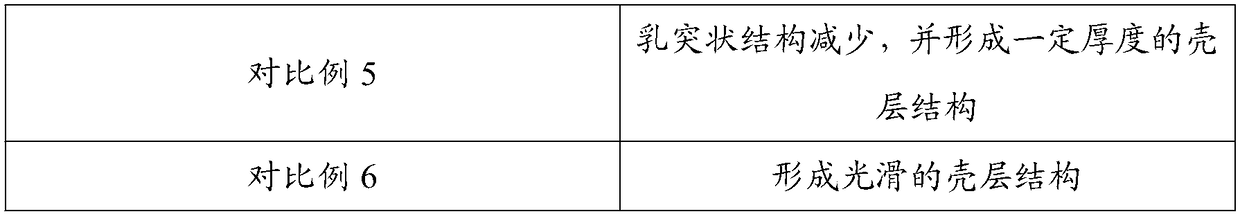

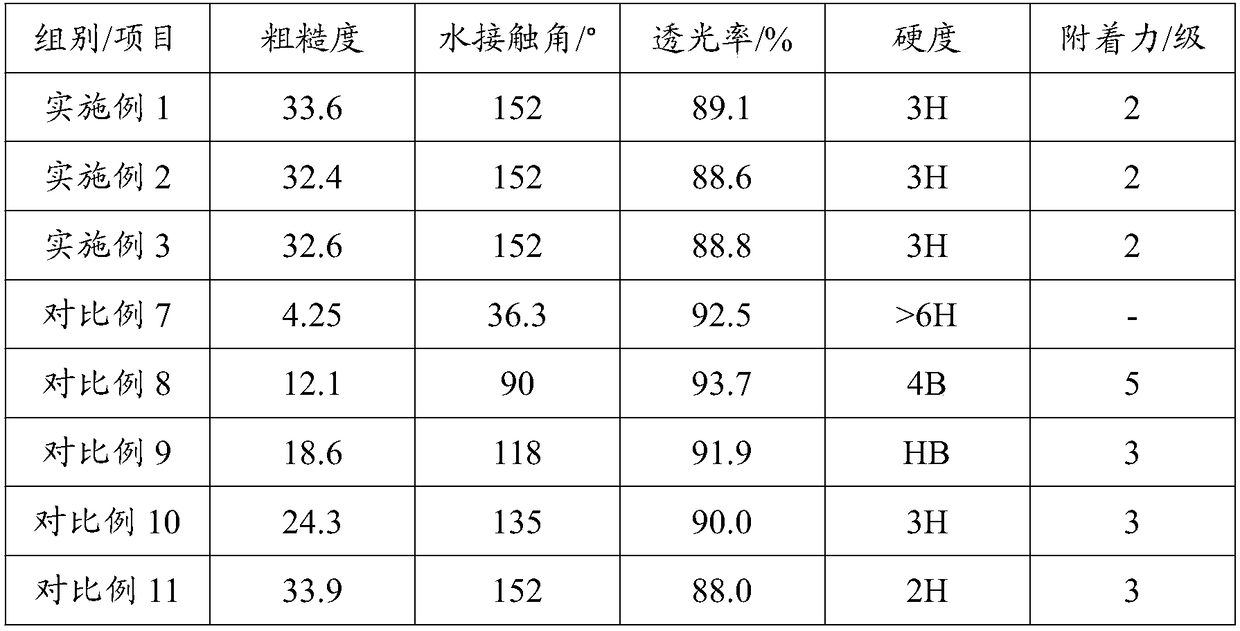

Examples

Embodiment 1

[0039] A transparent antibacterial superhydrophobic coating composed of polystyrene nanospheres and PS-TiO 2 Composed of structural composite particles, the polystyrene nanospheres are composed of the following raw materials in parts by weight: 48 parts of styrene, 2 parts of acrylic acid, 0.5 parts of sodium dodecylbenzenesulfonate, 0.2 parts of polyvinylpyrrolidone, azobisiso 0.2 parts of butyronitrile, 450 parts of distilled water.

[0040] The above-mentioned polystyrene nanospheres can be replaced by any one of polyacrylamide nanospheres and polymethyl methacrylate nanospheres.

[0041] The present embodiment is a kind of transparent antibacterial superhydrophobic coating, and the preparation method of described polystyrene nanosphere is: mix styrene, acrylic acid, sodium dodecylbenzene sulfonate, polyvinylpyrrolidone, azobisisobutyronitrile and Mix with distilled water, disperse at a high speed for 10 minutes, place in a four-necked flask, and centrifuge in a water bath...

Embodiment 2

[0054] A transparent antibacterial superhydrophobic coating composed of polystyrene nanospheres and PS-TiO 2 Composed of structural composite particles, the polystyrene nanospheres are composed of the following raw materials in parts by weight: 45 parts of styrene, 1 part of acrylic acid, 0.3 part of sodium dodecylbenzenesulfonate, 0.1 part of polyvinylpyrrolidone, azobisiso 0.1 part of butyronitrile, 440 parts of distilled water.

[0055] The above-mentioned polystyrene nanospheres can be replaced by any one of polyacrylamide nanospheres and polymethyl methacrylate nanospheres.

[0056] The present embodiment is a kind of transparent antibacterial superhydrophobic coating, and the preparation method of described polystyrene nanosphere is: mix styrene, acrylic acid, sodium dodecylbenzene sulfonate, polyvinylpyrrolidone, azobisisobutyronitrile and Mix with distilled water, disperse at high speed for 8 minutes, place in a four-necked flask, and centrifuge in a water bath at 78°...

Embodiment 3

[0069] A transparent antibacterial superhydrophobic coating composed of polystyrene nanospheres and PS-TiO 2 Composed of structural composite particles, the polystyrene nanospheres are composed of the following raw materials in parts by weight: 51 parts of styrene, 3 parts of acrylic acid, 0.7 parts of sodium dodecylbenzenesulfonate, 0.3 parts of polyvinylpyrrolidone, azobisiso 0.3 parts of butyronitrile, 460 parts of distilled water.

[0070] The above-mentioned polystyrene nanospheres can be replaced by any one of polyacrylamide nanospheres and polymethyl methacrylate nanospheres.

[0071] The present embodiment is a kind of transparent antibacterial superhydrophobic coating, and the preparation method of described polystyrene nanosphere is: mix styrene, acrylic acid, sodium dodecylbenzene sulfonate, polyvinylpyrrolidone, azobisisobutyronitrile and Mix with distilled water, disperse at a high speed for 12 minutes, place in a four-necked flask, and centrifuge in a water bath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com