High-covering high-luminance quantum dot diffusion barrier and preparation method and application thereof

A quantum dot and diffusion film technology, applied in the field of quantum dot diffusion film, can solve the problems of general light uniformity and large luminance loss of quantum dot backlight diffusion plate, and achieve large luminance loss, good atomization and covering effect, The effect of good luminance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

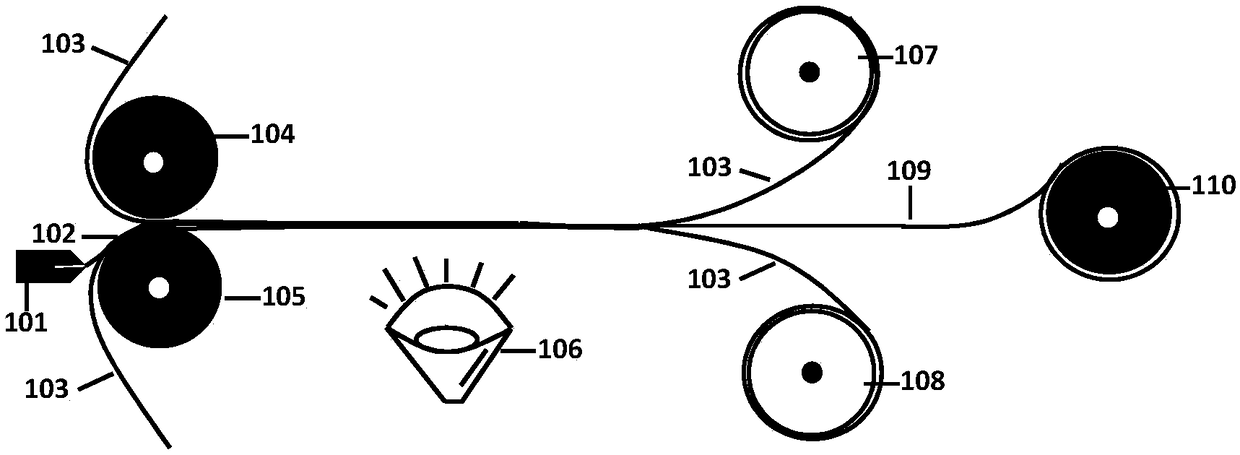

[0082] The preparation method of quantum dot film provided by the invention, described method comprises the following steps:

[0083] (1) Add fumed silica particles, titanium dioxide particles and silica particles into the adhesive and stir at high speed for 30 minutes to obtain a pre-dispersion of particles;

[0084] (2) adding red and green quantum dots to the pre-dispersion of the above particles and stirring at high speed for 30 minutes to obtain a quantum dot coating solution;

[0085] (3) Coating with a slot die automatic coating machine, coating the quantum dot coating liquid on the release surface of the release film, and extruding it with another release film through the slot die The release surface of the film is bonded, and the quantum dot composite film with three layers of film bonded is obtained by curing with ultraviolet light curing equipment;

[0086] (4) The two release films are peeled off, and the solidified quantum dot adhesive layer is obtained through t...

Embodiment 1

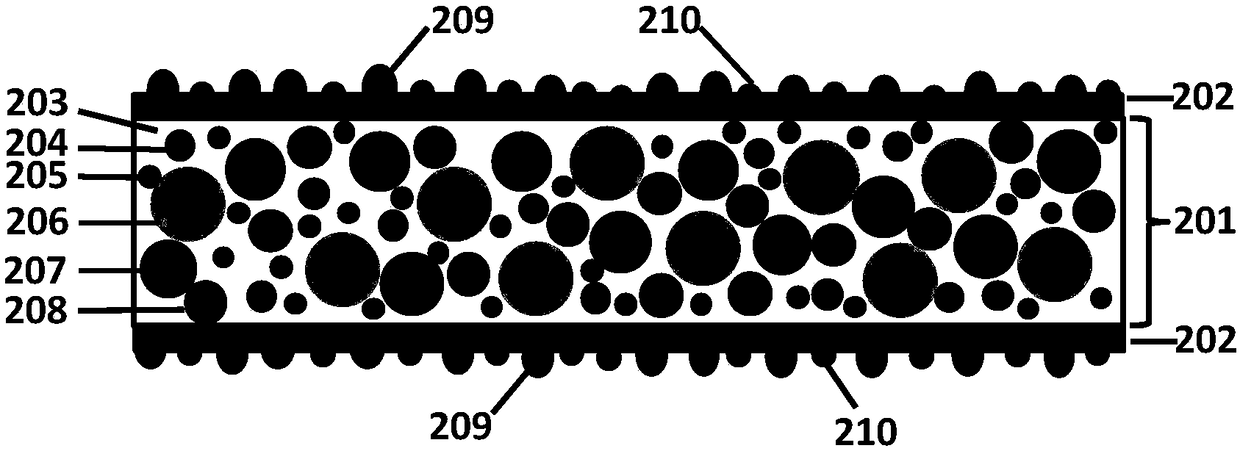

[0103] The present invention provides a quantum dot diffusion film with high coverage and high luminance. The quantum dot diffusion film includes a quantum dot substrate layer and a diffusion layer, and the diffusion layer is coated on the upper and lower surfaces of the quantum dot substrate layer; The quantum dot substrate layer is a single-layer film structure.

[0104] The quantum dot substrate layer comprises 100 parts by weight of polyester resin; 2 parts by weight of red quantum dots; 6 parts by weight of green quantum dots; 1 part by weight of fumed silica particles, the fumed silica particles The particle size distribution is 10-20nm; 5 parts by weight of titanium dioxide particles, the particle size of the titanium dioxide particles is 0.3 μm; 10 parts by weight of large particle size silicon dioxide particles, the particle size of the large particle size silicon dioxide The diameter is 2 μm; the thickness of the quantum dot substrate layer is 100 μm, and the quantum...

Embodiment 2

[0107] For the high-covering and high-brightness quantum dot diffusion film provided in Example 1, the quantum dot substrate layer includes 100 parts by weight of polyester resin, 2 parts by weight of red quantum dots, and 6 parts by weight of green quantum dots, 1 part by weight of fumed silicon dioxide particles, 5 parts by weight of titanium dioxide particles, and 10 parts by weight of large-diameter silicon dioxide particles, the thickness of the quantum dot substrate layer is 300 μm.

[0108] The diffusion layer includes 100 parts by weight of adhesive, 40 parts by weight of organic diffusion particles, and 10 parts by weight of inorganic diffusion particles, and the thickness of the diffusion layer is 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com