Quasi-continuous fiber laser device for modularized beam combining

A fiber laser, quasi-continuous technology, used in lasers, laser parts, semiconductor lasers, etc., can solve the problems of difficult adjustment, limited power supply, poor stability, etc., to prevent accidents, high power output, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] combine Figure 1 to Figure 7 , describes an embodiment of the present invention in detail, but does not limit the claims of the present invention in any way.

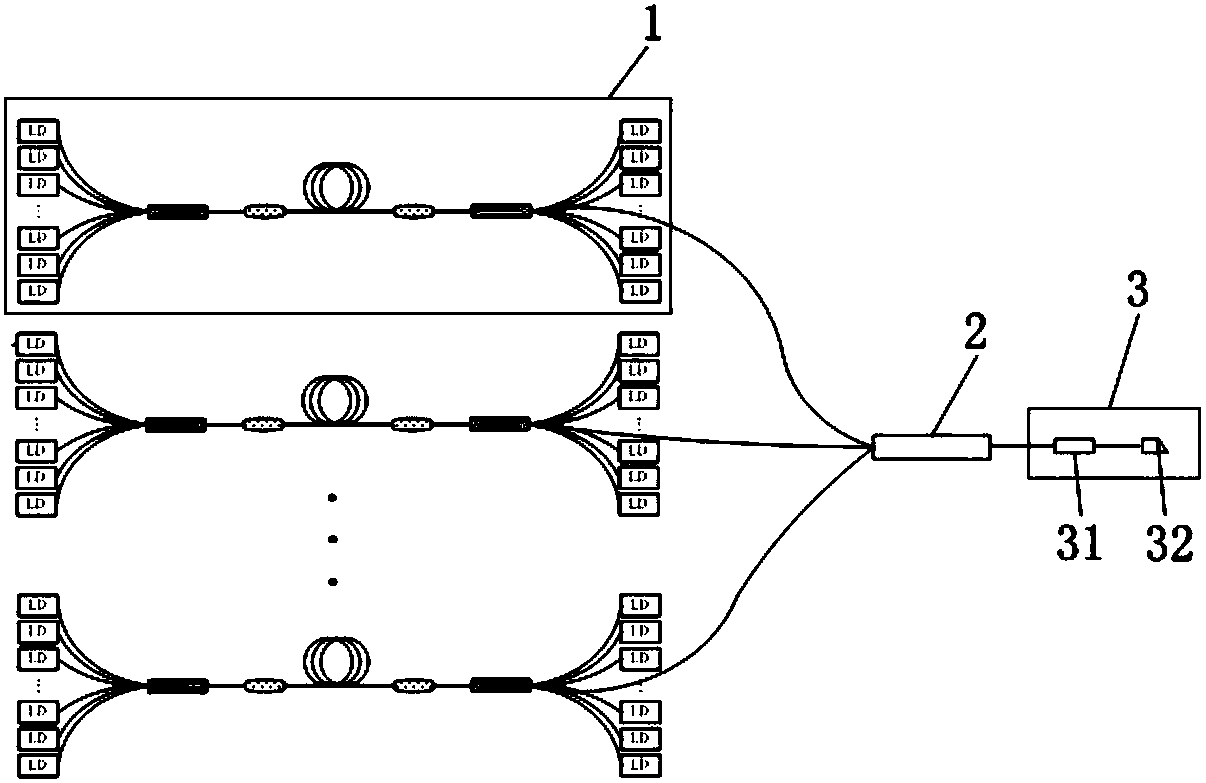

[0030] Such as figure 1 As shown, a modular beam combining quasi-continuous fiber laser includes a plurality of fiber laser modules 1, a beam combining device 2 and an output device;

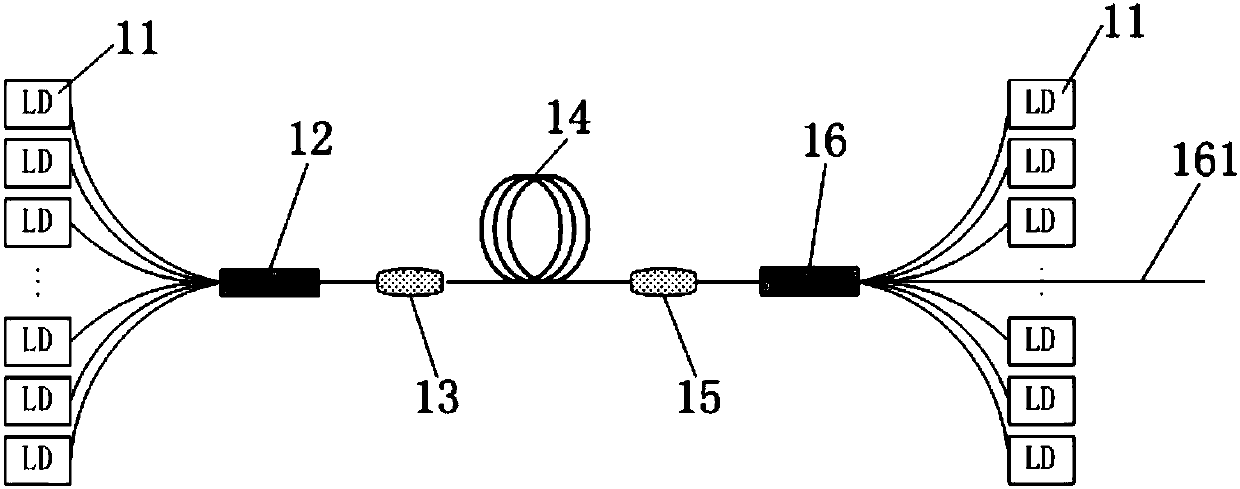

[0031] Such as figure 2 As shown, each fiber laser module 1 includes N+M pump lasers 11, a first beam combiner 12, a high reflection grating 13, a gain fiber 14, a low reflection grating 15 and a second beam combiner 16, the first combiner The beam combiner 12 has N input optical fibers, the second beam combiner has M+1 input optical fibers, N pump lasers 11 are connected to the N input optical fibers 121 of the first beam combiner 12, and the first beam combiner 12 The output fiber is fused with the input end of the high reflection grating 13, the output end of the high reflection grating 13 is fused with one end of the gain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com