Heterojunction solar cell having electroplated electrode and preparation method thereof

A solar cell and heterojunction technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as impact and extra cost environment, and achieve the effect of reducing process difficulty, high adsorption force, and reducing waste liquid discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

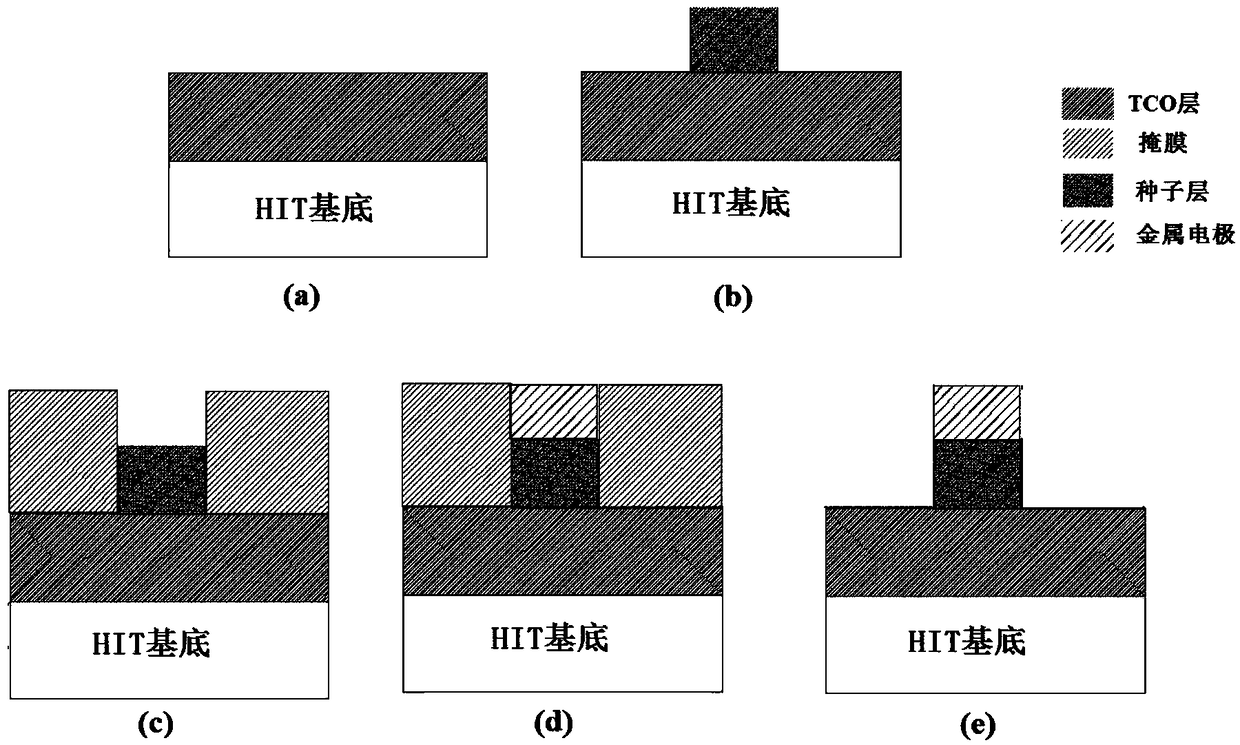

[0033] Such as figure 1 Shown, a kind of heterojunction solar cell preparation method with electroplated electrode comprises the following steps:

[0034] Step 1, preparing a transparent conductive thin film layer on the substrate of the heterojunction solar cell. The heterojunction solar cell substrate can add a transparent conductive thin film layer on the front or can add a transparent conductive thin film layer on the front and back of the heterojunction solar cell substrate. Here, adding a transparent conductive thin film layer on the front of the heterojunction solar cell substrate is Examples are explained in detail.

[0035] Step 2, forming a metal seed layer on a part of the transparent conductive film layer and forming a patterned mask on both sides of the metal seed layer. In the invention, a metal seed layer is firstly formed on a part of the transparent conductive film layer, and then a patterned mask is formed on both sides of the metal seed layer. Wherein, th...

specific Embodiment 2

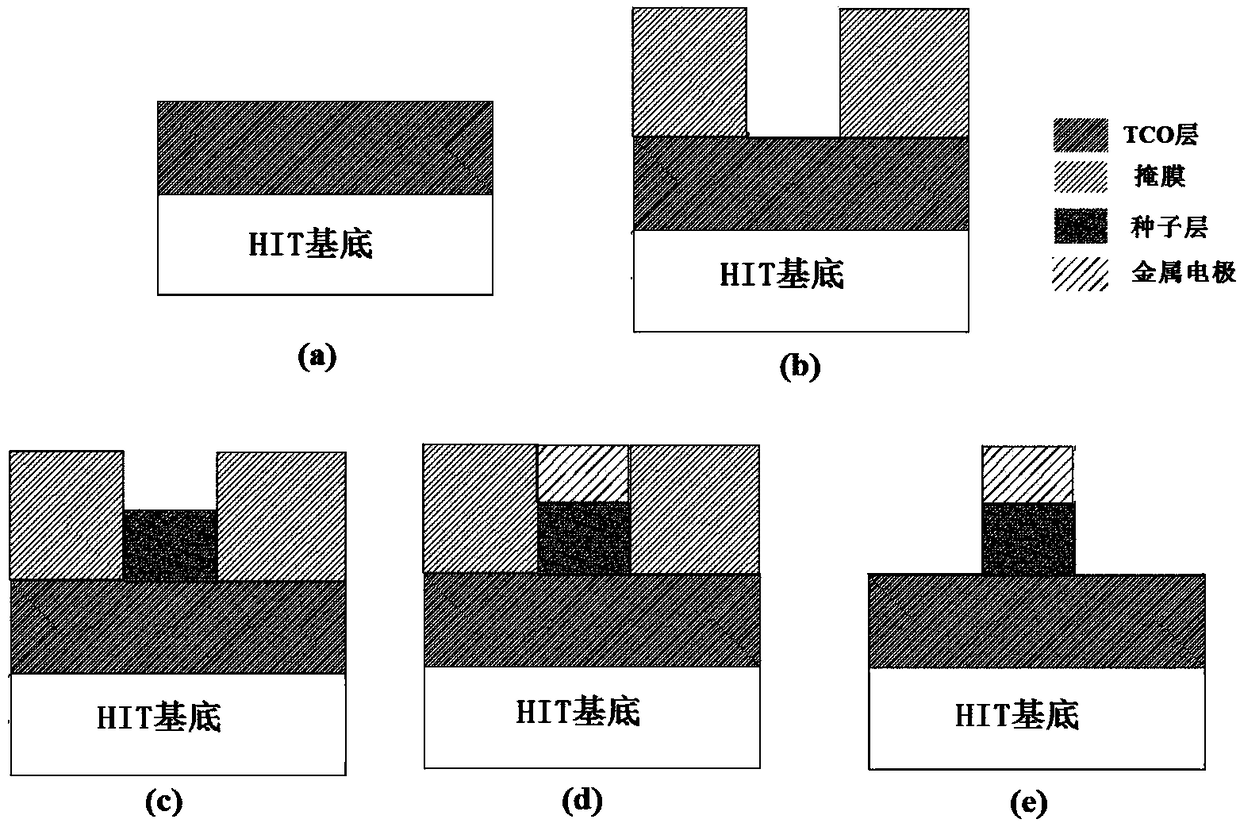

[0039] Such as figure 2 As shown, this embodiment is the same as the specific embodiment 1, except that in step 2, a patterned mask is first formed on both sides of the transparent conductive film layer, and then a metal seed layer is formed between the patterned masks.

specific Embodiment 3

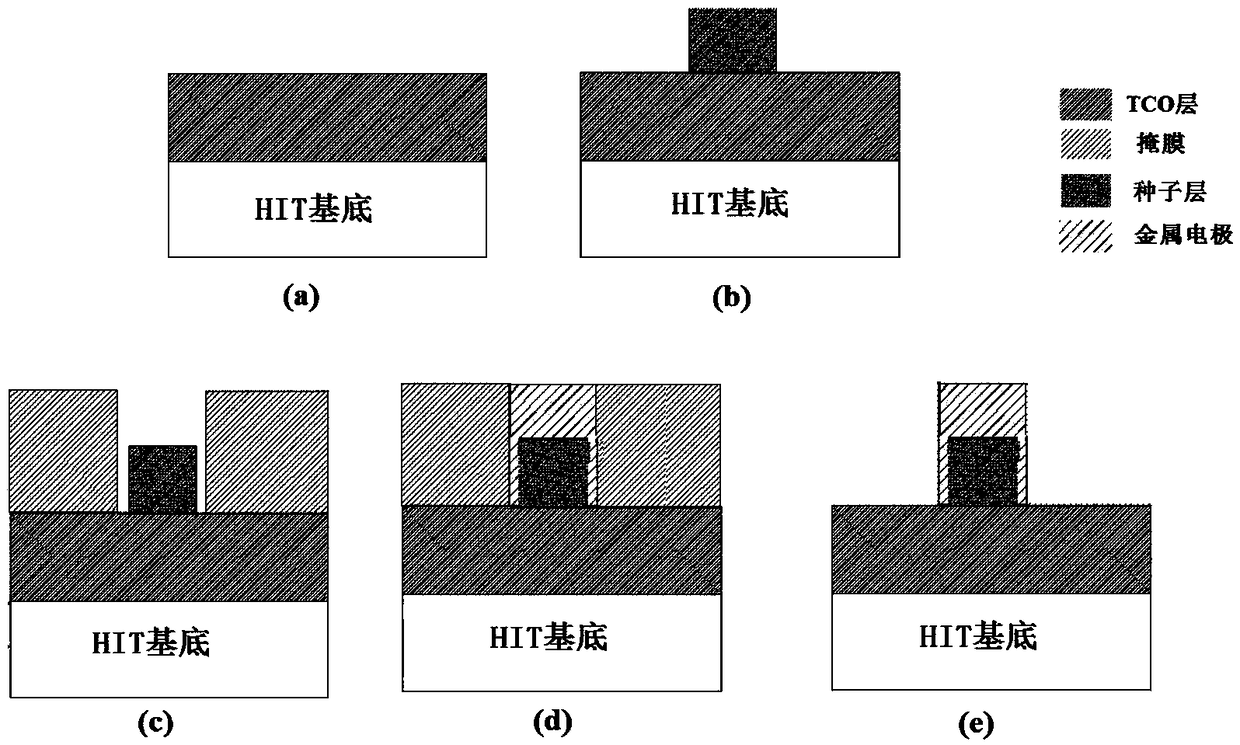

[0040] Such as image 3 Shown, a kind of heterojunction solar cell preparation method with electroplated electrode comprises the following steps:

[0041] Step 1, preparing a transparent conductive thin film layer on the substrate of the heterojunction solar cell. The heterojunction solar cell substrate can add a transparent conductive thin film layer on the front or can add a transparent conductive thin film layer on the front and back of the heterojunction solar cell substrate. Here, adding a transparent conductive thin film layer on the front of the heterojunction solar cell substrate is Examples are explained in detail.

[0042] Step 2, forming a metal seed layer on a part of the transparent conductive film layer and forming a patterned mask on both sides of the metal seed layer. In the invention, a metal seed layer is firstly formed on a part of the transparent conductive film layer, and then a patterned mask is formed on both sides of the metal seed layer. Wherein, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com