Method for treating white pollution

A solution, a technology of white pollution, applied in the field of environmental protection, to achieve the effect of reduced bonding density and full contact degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

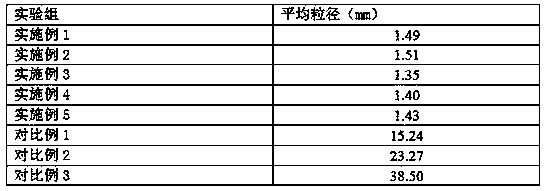

Examples

Embodiment 1

[0024] A solution to white pollution, characterized in that it comprises the following specific steps:

[0025] S1. Sieve the collected plastic raw materials, clean them, and perform mechanical destruction to reduce their volume;

[0026] S2. Put the pretreated raw materials into the soaking solution for soaking for 24 hours, and keep the soaking temperature at 37°C;

[0027] S3. Cleaning the soaked raw materials, adding them to the fermenter for fermentation and degradation;

[0028] S4. Collect the degraded mixed solution, waiting for secondary extraction and recycling.

[0029] The soaking liquid in the step S2 includes the following components in parts by weight: calcium hydroxide 7, sodium hydroxide 4, ammonium chloride 12-30, ammonium bicarbonate 15, triethanolamine 8, glycerol 4.

[0030] Further, the concentration of the soaking solution is 0.16moL / L.

[0031] The soaking solution in the present invention can be combined with the functional groups of the network ske...

Embodiment 2

[0036]A solution to white pollution, characterized in that it comprises the following specific steps:

[0037] S1. Sieve the collected plastic raw materials, clean them, and perform mechanical destruction to reduce their volume;

[0038] S2. Put the pretreated raw materials into the soaking solution for soaking for 24-72 hours, and keep the soaking temperature at 37-60°C;

[0039] S3. Cleaning the soaked raw materials, adding them to the fermenter for fermentation and degradation;

[0040] S4. Collect the degraded mixed solution, waiting for secondary extraction and recycling.

[0041] The soaking solution in the step S2 includes the following components in parts by weight: calcium hydroxide 7-19, sodium hydroxide 4-19, ammonium chloride 12-30, ammonium bicarbonate 15-18, triethanolamine 8-16 , Glycerol 4-9.

[0042] Further, the concentration of the soaking solution is 0.16moL / L-0.48moL / L.

[0043] Further, the fermentation degradation process in the step S3 is: the total...

Embodiment 3

[0047] A solution to white pollution, characterized in that it comprises the following specific steps:

[0048] S1. Sieve the collected plastic raw materials, clean them, and perform mechanical destruction to reduce their volume;

[0049] S2. Put the pretreated raw materials into the soaking solution for soaking for 48 hours, and keep the soaking temperature at 49°C;

[0050] S3. Cleaning the soaked raw materials, adding them to the fermenter for fermentation and degradation;

[0051] S4. Collect the degraded mixed solution, waiting for secondary extraction and recycling.

[0052] The soaking liquid in the step S2 includes the following components in parts by weight: calcium hydroxide 13, sodium hydroxide 12, ammonium chloride 21, ammonium bicarbonate 17, triethanolamine 12, and glycerol 7.

[0053] Further, the concentration of the soaking solution is 0.32moL / L.

[0054] Further, the fermentation degradation process in the step S3 is: the total number of colonies added is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com