Dry purification process for low grade bentonite

A technology of dry purification and bentonite, which is applied in chemical instruments and methods, solid separation, aluminum silicate, etc., can solve the problems of low recovery rate, limited purification effect, and small increase in montmorillonite content, and achieve an increase in recovery rate , Reduce use limitations, increase the effect of increasing the content of montmorillonite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

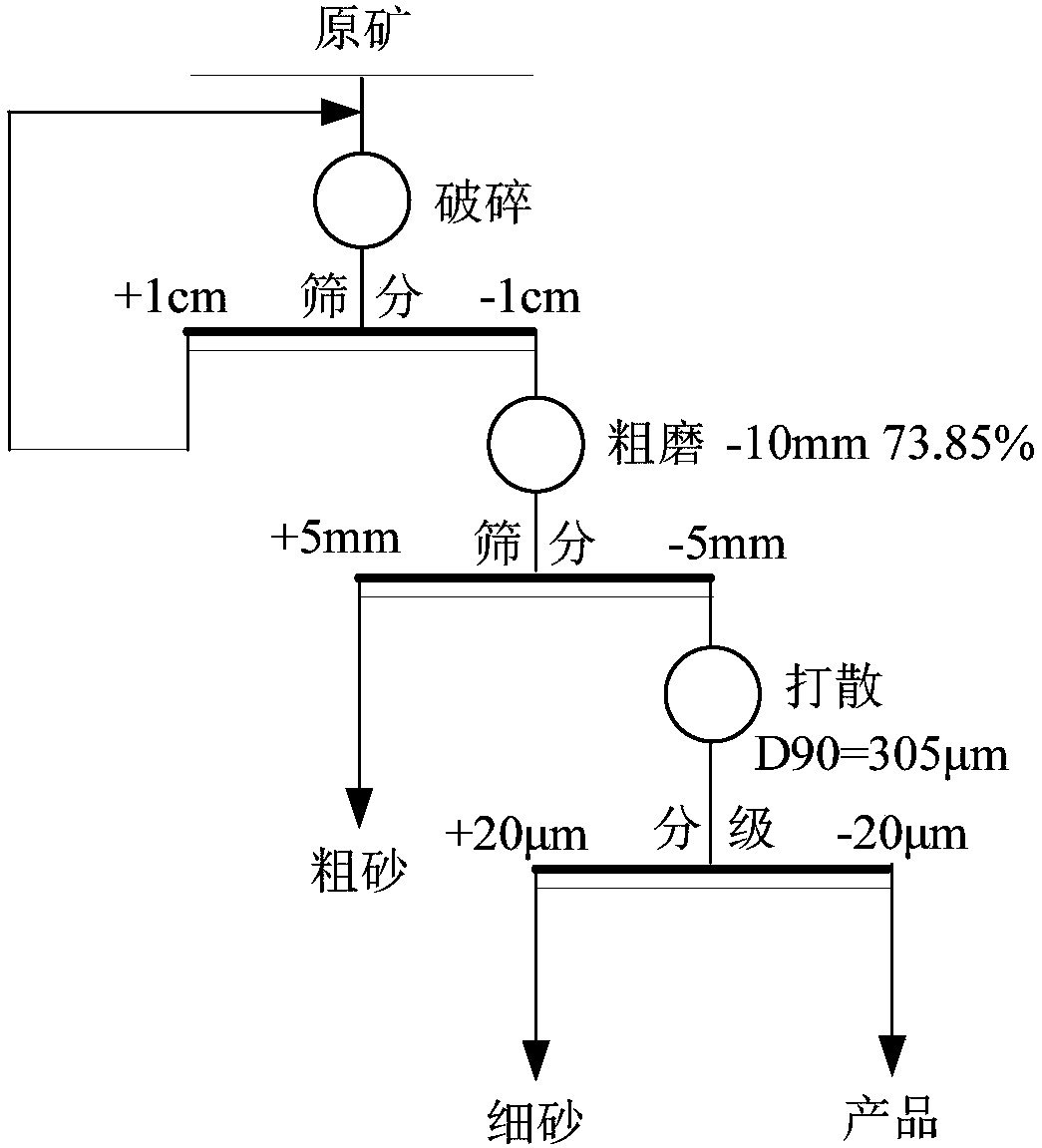

[0049] The dry purification process of the low-grade bentonite of the present embodiment, its process flow chart is shown in figure 2 , including the following steps:

[0050] 1) crushing low-grade bentonite with a montmorillonite content of 55% and a sand content of 33% to a particle size of less than 1 cm to obtain a crushed product;

[0051] 2) The crushed product is subjected to coarse grinding and grinding, the mill speed of the coarse grinding and grinding is 2500r / min, the grinding time of the flash grinding is 20s, and the weight percentage of minerals with a grinding particle size of 10mm or less is 73.85% , to obtain the grinding product;

[0052] 3) Sieve the grinding product with a sieving particle size of 5 mm, directly discharge the coarse-grained product on the sieve, and obtain the under-sieve product after sieving;

[0053] 4) Break up the under-sieve product, the speed of the breaker is 3500r / min, the time for breaking up is 3min, and the break-up particle...

Embodiment 2

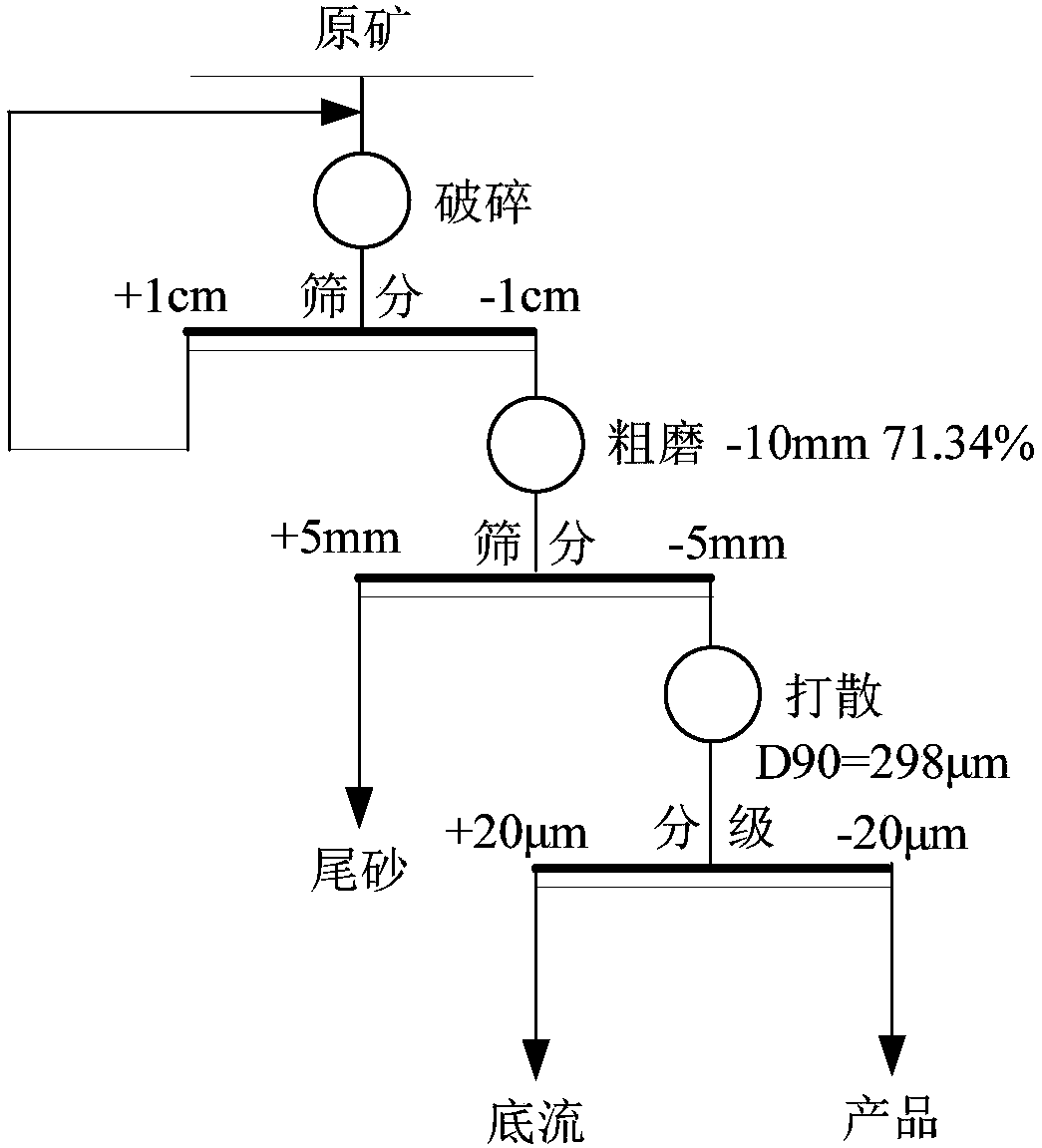

[0056] The dry purification process of the low-grade bentonite of the present embodiment, its process flow chart is shown in image 3 , including the following steps:

[0057] 1) crushing low-grade bentonite with a montmorillonite content of 48% and a sand content of 41% to a particle size of less than 1 cm to obtain a crushed product;

[0058] 2) The crushed product is subjected to coarse grinding and grinding, the mill speed of the coarse grinding and grinding is 2500r / min, the grinding time of the flash grinding is 40s, and the weight percentage of minerals with a grinding particle size of 10mm or less is 71.34% , to obtain the grinding product;

[0059] 3) Sieve the grinding product with a sieving particle size of 5 mm, directly discharge the coarse-grained product on the sieve, and obtain the under-sieve product after sieving;

[0060] 4) Break up the under-sieve product, the speed of the breaker is 3500r / min, the breakup time is 3min, the breakup particle size is D90=2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D90 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com