Ceramic substrate continuous laser cutting device and ceramic substrate continuous laser cutting method

A technology of laser cutting and ceramic substrates, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult substrate hardness and fragile cutting, so as to solve the problem of fragmentation, improve cutting efficiency, and realize The effect of automated mechanized operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

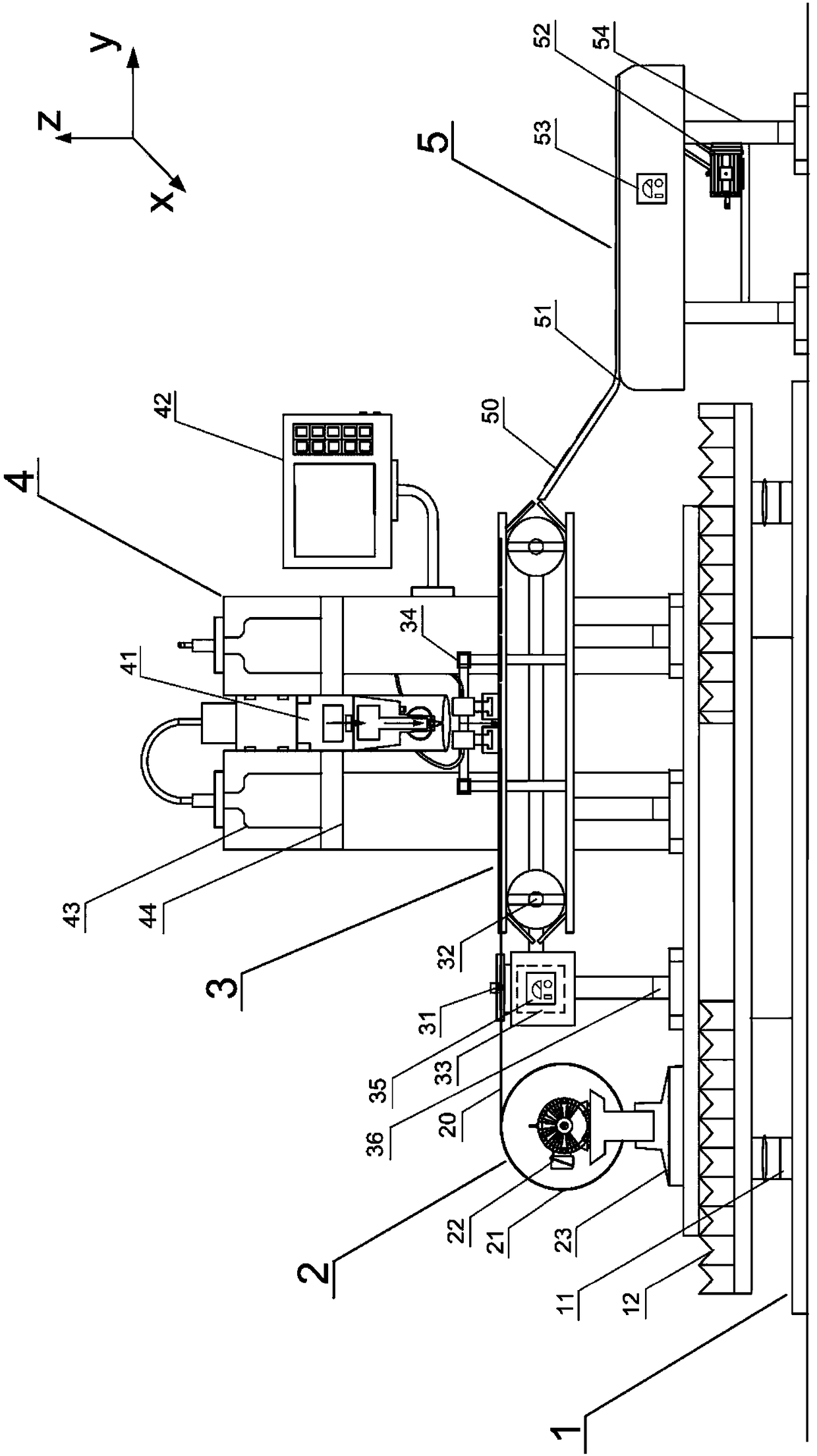

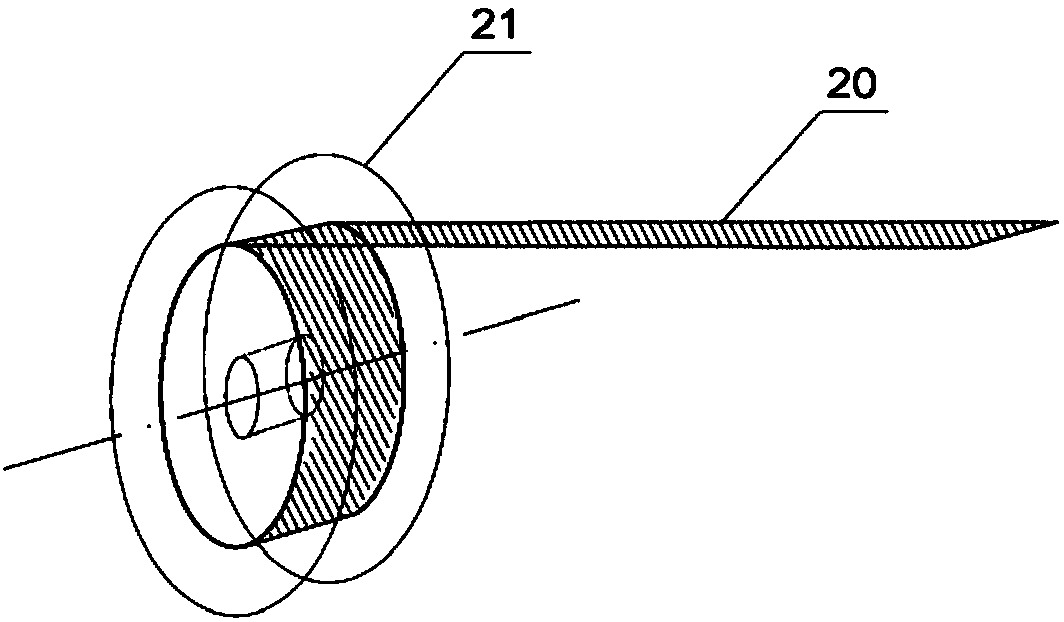

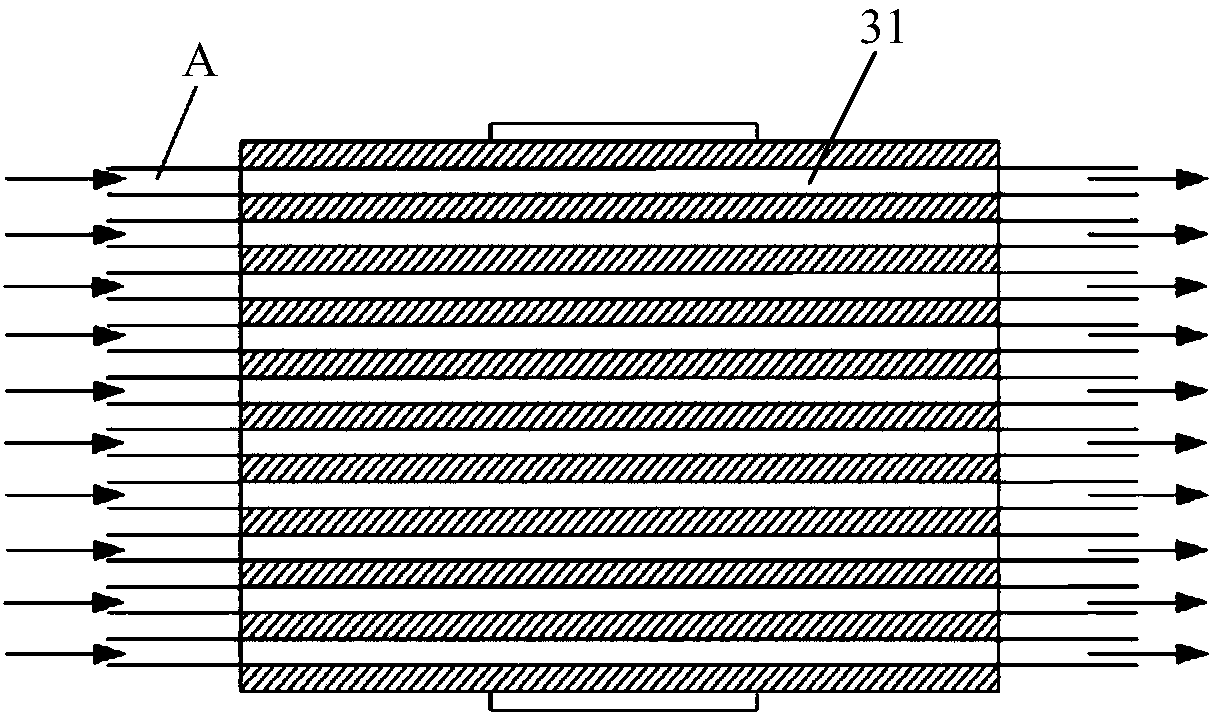

[0039] The ceramic substrate continuous laser cutting device provided by the present invention, such as Figure 1-7 As shown, it includes: a two-dimensional motion component 1 , a substrate film feeding component 2 , a cutting platform component 3 , a laser light source and a computer component 4 and a substrate discharging component 5 . The two-dimensional motion component 1 includes a mobile platform 11 that can move along the x-axis direction and a mobile platform 12 that can move along the y-axis direction. The substrate film feeding assembly 2 includes a silicon carbide thin film ceramic substrate 20 to be cut, a horizontal motor 22 that drives the substrate reel 21 to rotate, and a bracket 23 fixed on the two-dimensional motion assembly 1 . In the cutting platform assembly 3, it includes a positioning mechanism 31 for determining the position w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com