Tool for machining second-stage blade of free turbine of aero-engine

An aero-engine, free technology, applied in the direction of metal processing machinery parts, metal processing equipment, positioning devices, etc., can solve the problems of unqualified processing of the secondary blade 4, small diameter of the ball-end cutter, poor rigidity, etc., and achieve the clamping method Stabilization, reduced tool vibration, and improved machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

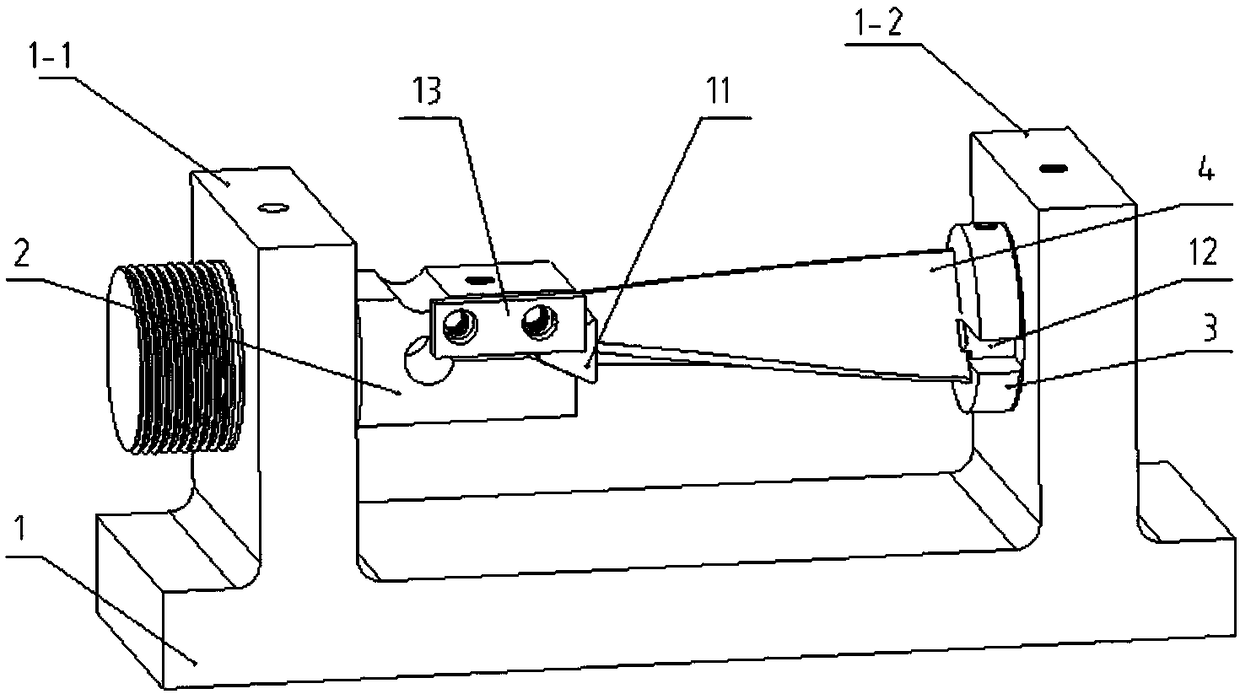

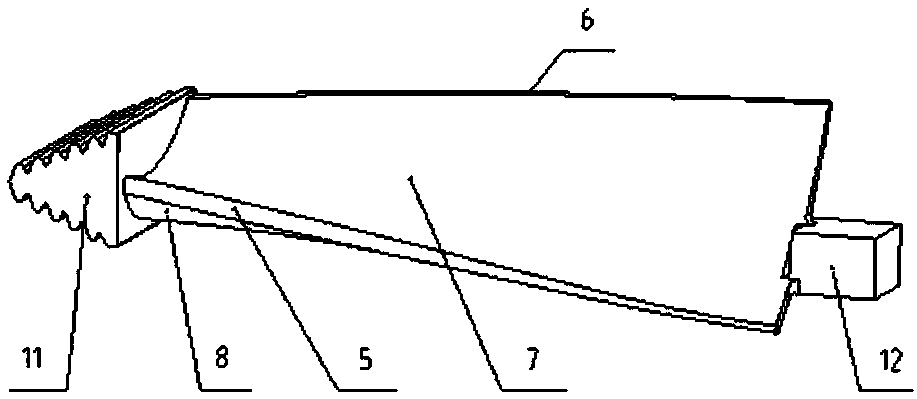

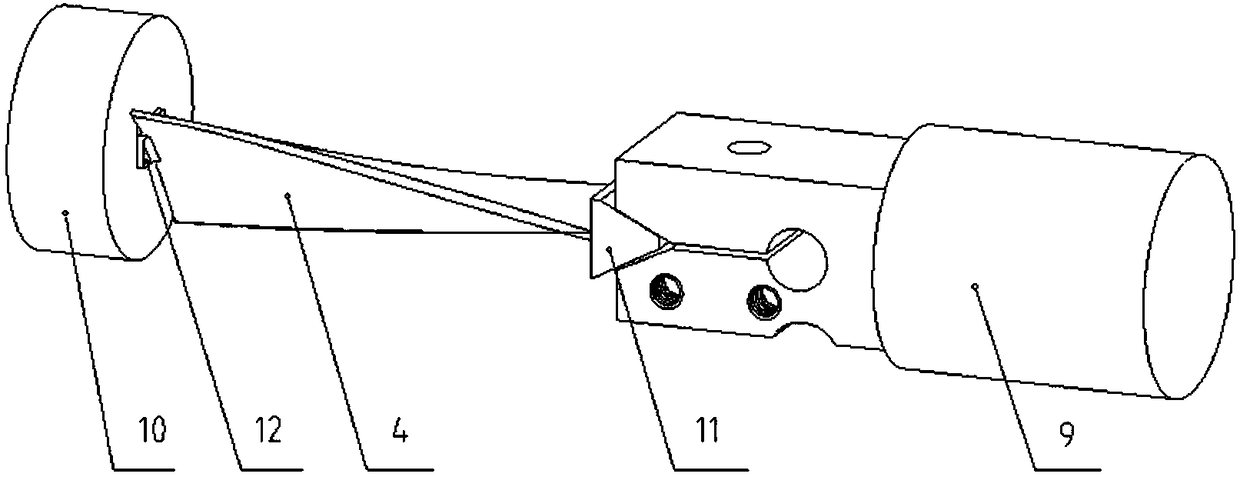

[0030] Such as figure 1 , a tooling for processing the second-stage blades of the free turbine of an aeroengine in this embodiment includes a base 1, and a vertical left support portion 1-1 and a right support portion 1 are provided on the left and right sides of the base 1 -2, a collet 2 is provided on the left supporting part, and a V-shaped tooth surface groove is provided on the right end surface of the collet 2;

[0031] A top cover 3 is provided on the inner side of the right supporting part, and a rectangular groove is provided on the left end surface of the top cover 3. The workbench 12 at the right end of the secondary blade 4 is fixedly matched with the rectangular groove, and the V-shaped teeth The tenon 11 on the left end of the surface groove and the secondary blade 4 is fixedly matched.

[0032] The bottom surface of the base 1 is flat and is attached to the worktable of the three-axis machining center. The left and right ends of the bottom of the base 1 are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com