Synthesis method of pharmaceutical intermediate m-aminobenzoic acid

The technology of an aminobenzoic acid and a synthesis method is applied in the field of synthesis of a pharmaceutical intermediate m-aminobenzoic acid, and can solve the problems of complicated process and low final yield, and achieves reduction of intermediate links, shortening of reaction time, and improvement of reaction yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

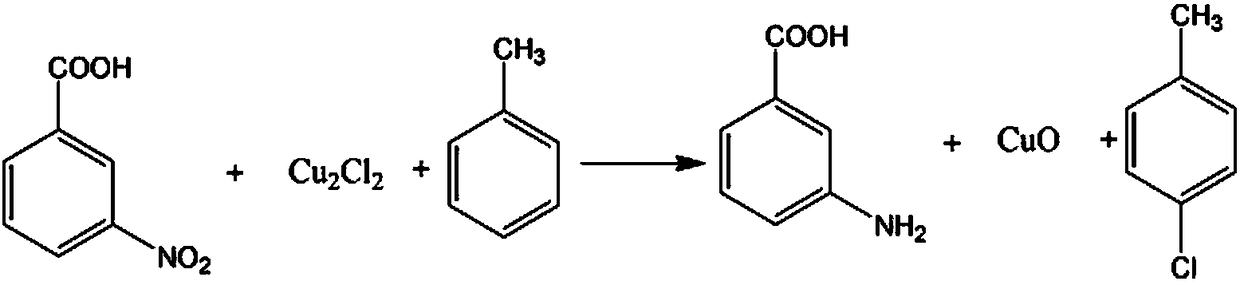

Image

Examples

example 1

[0011] Add 3 mol of cuprous chloride, 4 mol of toluene solution, and 5 mol of m-nitrobenzoic acid solution in the reaction vessel, raise the temperature of the solution to 60°C, control the stirring speed at 110rpm, keep it for 90min, and oxidize it with 10% mass fraction of hydrogen Adjust the pH of the solution to 9 with sodium solution, reduce the temperature of the solution to 5°C, and precipitate crystals, add 6L mass fraction of 30% ethanol solution for washing, mass fraction of 40% sodium chloride solution for washing, mass fraction of 50% nitromethane solution for washing , the mass fraction is 60% ethylenediamine solution washing, dehydrating with anhydrous sodium sulfate dehydrating agent, obtains 357.57g of finished m-aminobenzoic acid, yield 87%.

example 2

[0013] Add 3 mol of cuprous chloride, 4.5 mol of toluene solution, and 5 mol of m-nitrobenzoic acid solution in the reaction vessel, raise the temperature of the solution to 65°C, control the stirring speed at 120rpm, keep it for 100min, and use a mass fraction of 12% hydrogen Adjust the pH of the solution to 9.5 with sodium oxide solution, reduce the temperature of the solution to 7°C, and precipitate crystals, add 6L of 32% ethanol solution for washing, 42% of sodium chloride solution for washing, and 53% of nitromethane solution for washing Washing, washing with ethylenediamine solution with a mass fraction of 63%, and dehydrating with anhydrous magnesium sulfate dehydrating agent to obtain 374.01 g of finished m-aminobenzoic acid with a yield of 91%.

example 3

[0015] Add 3 mol of cuprous chloride, 5 mol of toluene solution, and 5 mol of m-nitrobenzoic acid solution in the reaction vessel, increase the temperature of the solution to 70 ° C, control the stirring speed at 130 rpm, keep it for 110 min, and use a mass fraction of 15% for hydrogen oxidation Adjust the pH of the solution to 10 with sodium solution, reduce the temperature of the solution to 10°C, and precipitate crystals, add 6L mass fraction of 35% ethanol solution for washing, mass fraction of 45% sodium chloride solution for washing, mass fraction of 56% nitromethane solution for washing , the mass fraction is 65% ethylenediamine solution washing, dehydrating with anhydrous sodium sulfate dehydrating agent, obtains 382.23g of finished product m-aminobenzoic acid, yield 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com