Synthetic method of sulfurized isobutylene

A technology of sulfided isobutylene and synthesis method, which is applied in the direction of organic chemistry, etc., and can solve problems such as inability to proceed with the reaction, sulfur denaturation, and poor melting of sulfur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

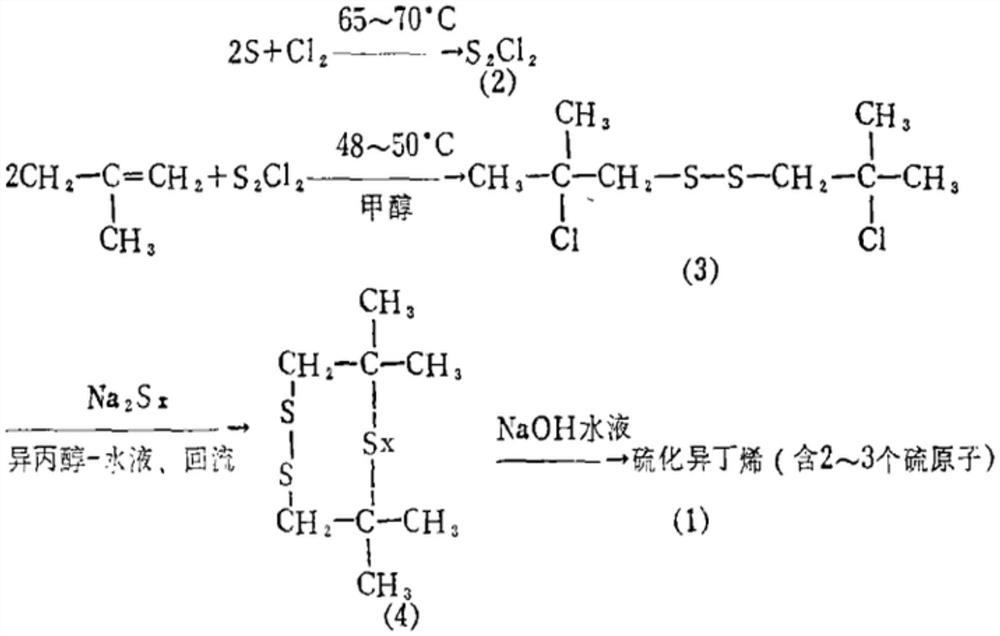

Image

Examples

preparation example Construction

[0019] The invention provides a method for synthesizing sulfurized isobutylene. The inventive method comprises the steps:

[0020] (i) Mix elemental sulfur and sulfurized isobutylene, add catalyst and heat to melt

[0021] The method for mixing sulfur and sulfurized isobutylene is not particularly limited, and may be a conventional mixing method, such as adding sulfurized isobutylene to sulfur and stirring and mixing. The applicable sulfur and sulfurized isobutylene are also not particularly limited, and may be commercially available sulfur and / or sulfurized isobutylene. In one example of the present invention, the sulfurized isobutylene is the sulfurized isobutylene prepared by the method of the present invention.

[0022] In an example of the present invention, the raw material elemental sulfur and sulfurized isobutylene are 5:1-1:1, preferably 4:1-1:1, better 3:1-1:1, and most preferably 2:1- 1:1 mass ratio for mixing to obtain mixed sulfur slurry.

[0023] The method o...

Embodiment 1

[0039] Add sulfur element and sulfurized isobutylene with a mass ratio of 1:1 into a high-temperature tank, add an organic base catalyst based on the weight of sulfur element, blow with nitrogen three to five times, heat and melt, and wait until the temperature rises to 120-200°C Use a sulfur pump to transport the material into the tubular reactor, add hydrogen sulfide and isobutylene (molar ratio 1:1.5) at the same time, control the reaction temperature at 145°C, and control the pressure at 1.54MPa, and the reaction is completed after 7 hours.

[0040] The above reaction was repeated in the same pipeline, and no pipeline blockage was found after 10 reactions. In addition, compared with the traditional high-pressure method, the pungent odor is significantly reduced.

Embodiment 2

[0042] Add sulfur element and sulfurized isobutylene in a high-temperature tank with a mass ratio of 1.5:1, add catalyst based on the weight of sulfur element, blow with nitrogen three to five times, heat and melt, and use a sulfur pump after the temperature rises to 120-200°C Transfer the material to the tubular reactor, add hydrogen sulfide and isobutylene (molar ratio: 1:1.8) at the same time, control the reaction temperature to 155°C, and control the pressure to 2.5MPa to complete the reaction after 5 hours.

[0043] The above reaction was repeated in the same pipeline, and no pipeline blockage was found after 10 reactions. In addition, compared with the traditional high-pressure method, the pungent odor is significantly reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com