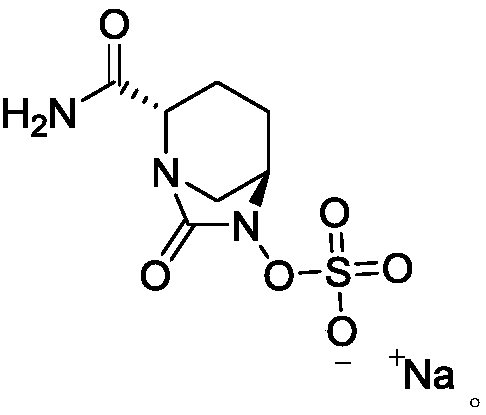

Method for preparing amorphous avibactam sodium by spray-drying

A kind of avibactam sodium, amorphous technology, applied in the field of preparation of amorphous avibactam sodium, can solve the problems of high energy consumption, long freeze-drying cycle, environmental hazards, etc., achieve low production cost, simple steps, The effect of reducing acid-alkaline wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A dichloromethane (100ml) solution of sodium isooctanoate (3.8g, 22mmol) was added dropwise to avibactam tetrabutylammonium salt (10g, 19.7mmol) in a dichloromethane solution (100ml), keeping the reaction temperature at At 20°C, the dropwise addition was completed in 20 minutes. After dripping and keeping warm for 3 hours, add 200ml of purified water for extraction, and the water phase enters the spray dryer (control the air inlet temperature at 150°C, the air outlet temperature at 80°C, and the injection volume at 75ml / min) to obtain 5.2g of solid matter. Yield 92%. The solid substance: amorphous, disorderly arrangement.

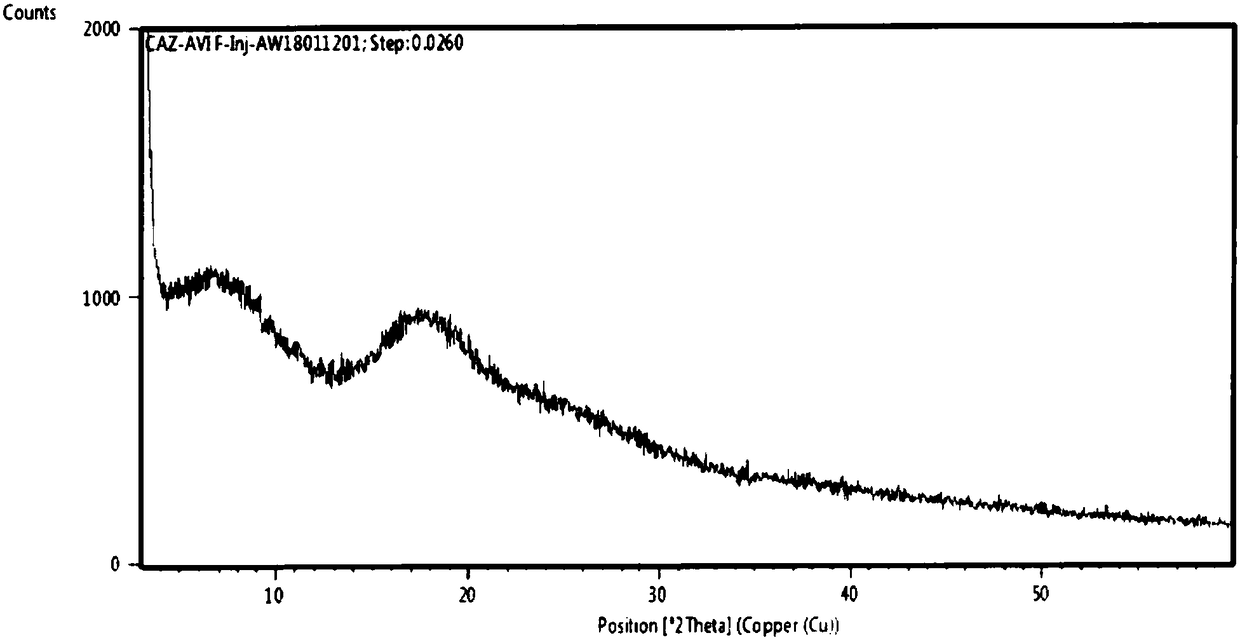

[0036] The above-mentioned solid is detected by two methods of XRD spectrum and DSC spectrum, as follows:

[0037] 1. The detection method of XRD pattern is as follows:

[0038] Instrument: PANalytical powder X-ray diffractometer;

[0039] Model: XpertPROMPD;

[0040] Test method: the target material is copper, the light pipe is set (40kv, 40mA)...

Embodiment 2

[0052] The n-butanol (200ml) solution of sodium isooctanoate (7.6g, 44mmol) is added dropwise in the n-butanol solution (200ml) of avibactam tetrabutylammonium salt (20g, 39.4mmol), keeping the reaction temperature at 20°C, 20min dropwise addition, heat preservation reaction for 3h, add 400ml of purified water for extraction, the water phase enters the spray dryer (air inlet temperature is 150°C, air outlet temperature is 80°C, injection volume is 75ml / min) to obtain solid drying The dry weight is 10.51g, and the yield is 93%. The solid substance: amorphous, disorderly arrangement.

Embodiment 3

[0054] The ethyl acetate (200ml) solution of sodium isooctanoate (7.6g, 44mmol) was added dropwise in the ethyl acetate solution (200ml) of avibactam tetrabutylammonium salt (20g, 39.4mmol), keeping the reaction temperature at 20°C, 20min dropwise addition, heat preservation reaction for 3h, add 400ml of purified water for extraction, the water phase enters the spray dryer (air inlet temperature is 150°C, air outlet temperature is 80°C, injection volume is 75ml / min) to obtain solid drying The dry weight is 10.29g, and the yield is 91%. The solid substance: amorphous, disorderly arrangement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com